12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting a seamless glow. But when you flip the switch, the lights at the end of the hall are barely flickering, while the ones near the power supply are blindingly hot. Or worse, you plug a strip directly into the wall and witness a literal explosion of sparks. The voltage you choose isn’t just a number; it is the difference between a fire hazard and a masterpiece.

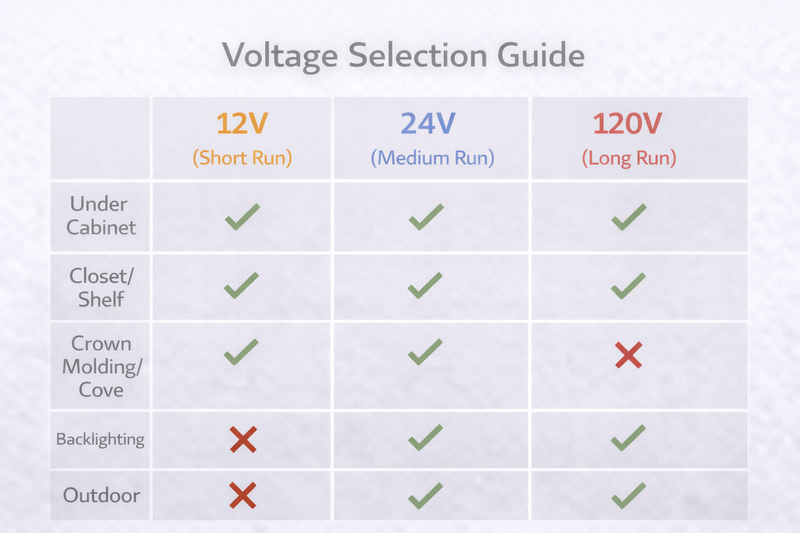

The choice depends entirely on run length and safety requirements. Choose 12V for short runs (under 5 meters) like automotive or cabinet lighting where precise cutting (every 10-25mm) is needed. Select 24V for professional home and commercial projects to minimize voltage drop over longer runs (up to 10 meters). Reserve 120V (High Voltage) strictly for massive outdoor landscaping or building outlines where you need 50+ meters on a single plug, but be aware of the safety risks.

In my years running a factory that supplies lighting designers across North America and Japan, I have seen seasoned electricians make rookie mistakes with voltage. I have seen 12V strips ruined because they were run 20 meters in a series, turning the far end into a dim orange glow. I have also seen dangerous 120V DIY setups that shocked homeowners. Today, let’s strip away the confusion. We are going to look at the physics of 12V DC, 24V DC, and 120V AC, so you never buy the wrong power supply again.

Why Is 12V DC the King of precision and Safety?

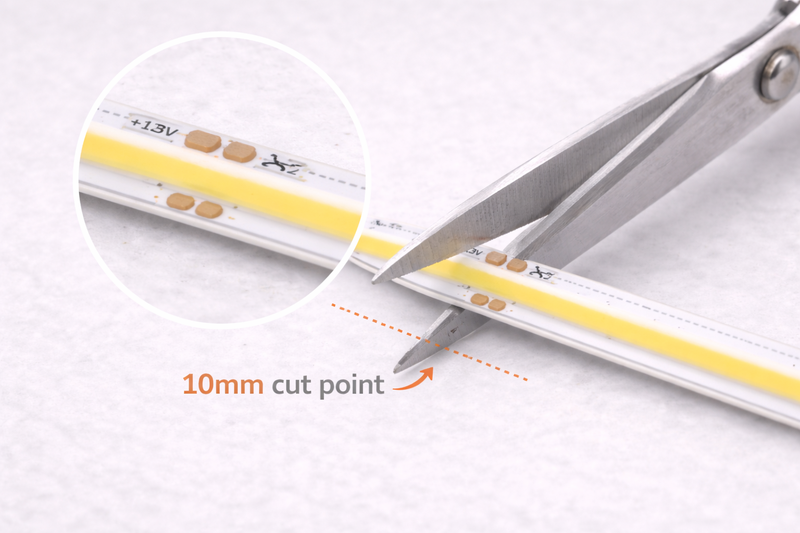

You are lighting a delicate glass display case or the inside of a car. You need to cut the light exactly at the corner, but standard strips only let you cut every 4 inches. You end up with dark spots or wire loops. The solution isn’t better scissors; it’s lower voltage.

12V LED strips offer the highest cutting precision, often allowing cuts every 10mm to 25mm. This makes them the absolute standard for intricate joinery, automotive interiors, and small-scale furniture lighting where every millimeter counts. Furthermore, 12V is the safest voltage to handle, eliminating shock hazards in wet areas like bathrooms.

Dive The Physics of the Cut Point

Why does voltage necessitate where you cut?

- The Circuitry: LEDs are typically wired in groups (series). A 12V circuit usually powers 3 LEDs in a series. A 24V circuit powers 6 or 7 LEDs. You can only cut between these groups.

- The Consequence: Because a 12V group is electrically "shorter," the cutting points are physically closer together.

Specific Use Cases for 12V:

- Automotive & Marine: Cars and boats run on 12V batteries. If you are retrofitting a camper van or lighting a yacht cabin, 12V is non-negotiable. You can wire our 12V SMD 5050 strips1 directly into the fuse box without a bulky transformer.

- Intricate Cabinetry: If you have a shelf that is exactly 482mm wide, a 24V strip with a 100mm cut point will force you to cut at 400mm, leaving 41mm of darkness on each side. A 12V COB strip2 with a 10mm cut point allows you to cut at 480mm, filling the shelf completely. Our COB HC-04-5 series even goes down to 5V for ultra-precision, but 12V is the best balance of power and precision.

The Current Drawback:

The downside of 12V is current (Amps).

- Formula: Watts = Volts × Amps.

- To get 100 Watts of light at 12V, you need roughly 8.3 Amps. That is a lot of current squeezing through thin copper.

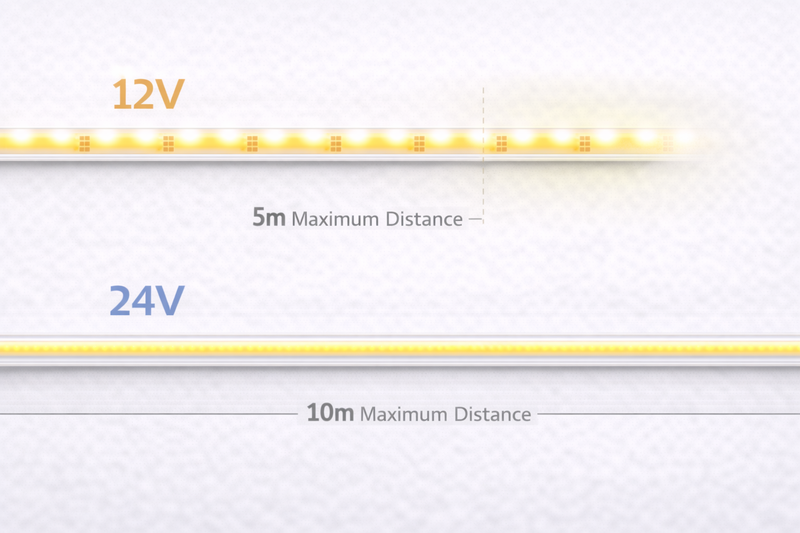

- Result: Heat. If you try to run 12V strips longer than 5 meters, the copper heats up, resistance increases, and the voltage drops. The end of the strip will look dim.

Why Is 24V DC the Professional Standard for Commercial Sourcing?

You are lighting a massive living room cove or a hotel lobby. You install 10 meters of light. You turn it on. The start is bright white, but the end is a warm, muddy yellow. The client refuses to pay. You have just fallen victim to "Voltage Drop."

24V systems carry electrical current twice as efficiently as 12V systems. By doubling the electrical "pressure," you significantly reduce the current (Amps) flowing through the copper traces. This allows for runs up to 10 meters (32 feet) in series with consistent brightness from start to finish, making 24V the default choice for general architectural lighting.

Efficiency and Copper Weight

In the B2B world, we sell 80% 24V3 strips and only 20% 12V. Here is why professionals prefer 24V.

1. Longer Runs, Fewer Power Supplies:

- With 12V, you must inject power every 5 meters. In a large room, that means running thick wires back to the transformer constantly.

- With 24V, you can often run 10 meters on a single power feed. This cuts your wiring labor in half and reduces the number of drivers you need to hide in the ceiling.

2. Better Thermal Management:

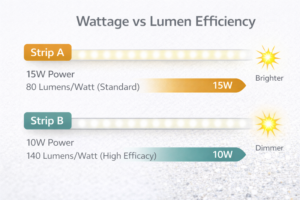

- Remember Watts = Volts × Amps?

- To get that same 100 Watts of light at 24V, you only need 4.1 Amps (half the current of 12V).

- Less current means less heat generated in the copper PCB4.

- Factory Insight: Our BG-253-3014-1200 series is a high-power strip (15W/m). We almost exclusively recommend the 24V version for this because the 12V version would get too hot and degrade the adhesive backing.

3. Brightness Consistency:

- Voltage drop is inevitable, but at 24V, the percentage drop is less noticeable.

- If a 12V strip drops 2V, it loses 16% of its power (visible dimming).

- If a 24V strip drops 2V, it loses only 8% of its power (barely visible).

- Our 24V SMD 2835 strips are designed with 3oz copper tracks to ensure that even at meter 10, the lux levels match meter 1.

The Trade-off:

The cutting unit is longer. A typical 24V strip cuts every 50mm (2 inches) or 100mm (4 inches). For hidden cove lighting, this doesn’t matter. But for visible shelves, check your measurements.

When Should You Use 120V (High Voltage) Strips?

You have a landscape project. The client wants to outline the entire roofline of a warehouse—100 meters of continuous light. If you use 24V, you will need 10 power supplies and a mess of wiring. Is there a way to plug it in once and be done?

120V (or 220V) "Driverless" strips are designed for massive distances. They connect directly to mains power and can run 50 meters (165 feet) or more on a single plug without noticeable voltage drop. However, they carry a high risk of electric shock, require heavy insulation, cannot be cut precisely, and often exhibit a visible 60Hz flicker.

Great Distance, Greater Risk

These are often called "Rope Lights" rather than strip lights because of the thick tubing required for safety.

The Major Advantage: Distance:

- Because the voltage is so high (120V), the current is tiny.

- You can run huge lengths—perimeter fencing, skyscraper outlines, stadium stairs—using just one power source at the start.

The Serious Downsides:

- Safety Hazard5: Cutting a 12V wire might spark; cutting a 120V wire can kill you. These must be installed by licensed professionals and usually require thick, ugly PVC casing to meet code.

- The "Strobe" Effect: 12V and 24V DC (Direct Current) provide constant, smooth light. 120V AC (Alternating Current) turns on and off 60 times a second. This creates a subtle flicker. While some new models have rectifiers, many cheap ones will give sensitive people headaches.

- Cutting Limitations: You can usually only cut these every 0.5 meters or 1 meter. Precision is impossible. You will have excess slack at the end of runs that you have to hide.

- No Dimming (Usually): Most standard 120V rope lights do not dim well without expensive, specialized TRIAC dimmers that often cause buzzing.

Manufacturing Reality:

In my factory, we focus on 12V and 24V low-voltage solutions6 because they offer higher quality light (CRI >90) and safety. We rarely recommend 120V strips unless it is for temporary construction site lighting or very basic outdoor holiday decor where color rendering doesn’t matter.

Can You Mix 12V and 24V in the Same Project?

You are smart. You bought 24V for the ceiling cove and 12V for the cabinets. But now you have a pile of different power supplies, and your installer just plugged the 12V strip into the 24V box. Pop. Smoke. Darkness. Mixing voltages is a logistical minefield.

While possible, mixing voltages increases complexity and failure risk. A 12V strip plugged into a 24V driver will instantly burn out. A 24V strip on a 12V driver won’t light up. For simplicity and inventory management, standardizing on 24V for the entire project is usually the best strategy, using step-down converters only if specific 12V fixtures are unavoidable.

Project Standardization Strategy

When I advise my wholesaler clients ("Tom", for example), I always tell them: Standardize your inventory.7

The Problem with Mixing:

- Human Error: On a busy job site, a tired apprentice will grab the wrong transformer. It happens every day.

- Controller Confusion: If you are using dimmers or RGB controllers, a 12V controller might look identical to a 24V8 one. If you mix them up, you blow the control unit.

Why 24V Wins the Standardization War:

- Versatility: You can use 24V for both long coves (due to low voltage drop) and short cabinets (if you accept the 50mm cut point).

- Availability: Most high-end controls (DALI, 0-10V, DMX) are native to 24V.

- Power Density: Our HC-12-24 series COB strips offer beautiful, dot-free light at 24V. They are robust enough for the main room but flexible enough for joinery.

The Exception:

If you are doing a project that involves addressable LEDs (Magic Color Chasing Lights), like our HC-05-5 Pixel series, you might be forced to use 5V or 12V.

- Pixel protocols (like WS2812B) often run on 5V.

- In this case, you must run a separate power bus. Do not try to share the 24V main line without a Buck Converter (voltage reducer).

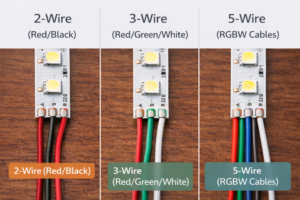

The Golden Rule:

Label your wires. If you must mix voltages, use different colored wires (e.g., Red/Black for 12V, Red/White for 24V) or label the ends immediately. It saves thousands of dollars in blown diodes.

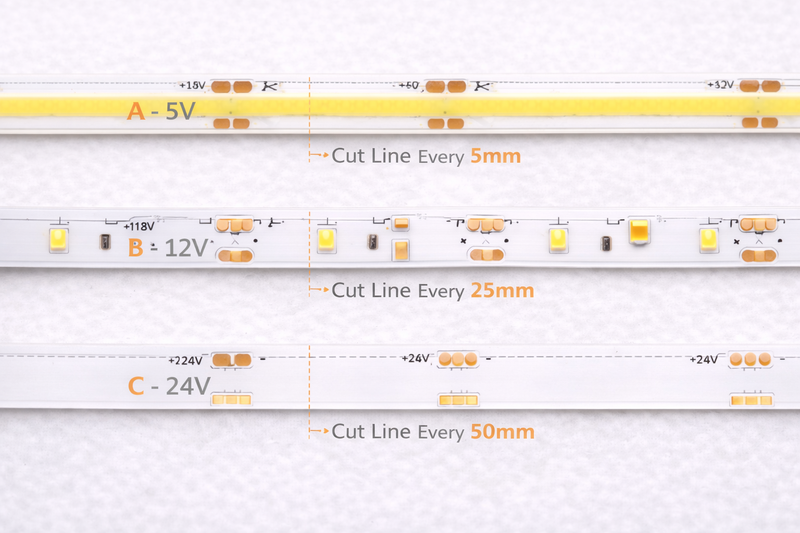

How Do "Cutting Units" Differ Between Voltages?

We touched on this, but let’s look at the actual specs. You are bidding on a job requires LED strips embedded in a marble floor. The slot is cut. It is permanent. If your light is 10mm too long, you can’t just "squeeze it in."

Voltage dictates the cutting interval. Lower voltage equals shorter cutting units. A 5V strip can be cut every LED (roughly 5-8mm). A 12V strip usually cuts every 3 LEDs (25mm). A 24V strip cuts every 6 LEDs (50-100mm). For precision inlaid work, lower voltage is the only way to ensure the light fits the channel perfectly.

The Specification Breakdown

Let’s look at the actual data from our factory production lines to give you real numbers.

5V – The Pixel Standard:

- Our HC-05-5 series runs on 5V.

- Cutting Length: Every 5mm (basically every single LED).

- Use: Digital chasing effects, PC gaming setups, incredibly tight model making.

12V – The Joinery Standard:

- Our HC-12-12 series (COB) runs on 12V.

- Cutting Length: Every 10mm to 25mm.

- Use: Kitchen cabinets, wardrobe rails, bathroom niches.

- Note: Even massive SMD 5050 chips in 12V usually cut every 50mm, but COB technology has brought this down to 10mm.

24V – The Architectural Standard:

- Our BG-252-3014 series runs on 24V.

- Cutting Length: 50mm or 100mm.

- Use: Ceiling coves, wall grazing, baseboards.

- Why: The circuit groups 6 or 7 LEDs to handle the 24 volts efficiently. You cannot physically cut inside that group without breaking the circuit.

The "Hybrid" 24V COB:

We have developed a 24V COB strip (Model HC-12-24) that maintains a relatively short cutting length (roughly 30-40mm) by using specialized circuit design. This is the best of both worlds—the long-run capability of 24V with the decent flexibility of cutting.

Conclusion

The voltage you choose dictates the success of your install.

- Choose 12V only for short runs (<5m), vehicles, or when you need extreme cutting precision (10-25mm) for custom furniture.

- Choose 24V for 95% of residential and commercial projects. It allows for long runs (10m) with minimal voltage drop, uses thinner wires, and runs cooler.

- Choose 120V only for massive outdoor perimeters where you cannot hide transformers and safety/flicker is less of a concern.

At Rhstriplighting, we build our 24V strips with thicker 3oz copper to make them the robust workhorse for your business. Stop guessing, and start specifying the right voltage for the job.

-

Explore this link to understand the versatility and applications of 12V SMD 5050 strips in various lighting projects. ↩

-

Discover the benefits of using 12V COB strips for precise lighting solutions and how they can enhance your projects. ↩

-

Explore this link to understand the advantages of 24V LED strips, including efficiency and installation benefits. ↩

-

Learn how copper PCBs enhance thermal management in LED strips, ensuring longevity and performance. ↩

-

Learn about the serious risks associated with 120V lighting, including installation requirements and safety measures to take. ↩

-

Explore this link to understand why low-voltage lighting is safer and offers better quality light, making it ideal for various applications. ↩

-

Exploring this resource will provide insights into how standardization can reduce errors and improve efficiency in inventory management. ↩

-

This link will explain the advantages of using 24V in lighting, including versatility and compatibility with high-end controls. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…

2-Wire vs 3-Wire vs 5-Wire LED Rope Lights Explained: Are You Wiring Your Project for Failure?

You have landed a lucrative commercial lighting contract, the design is approved, and the budget is set. But when the…