2-Wire vs 3-Wire vs 5-Wire LED Rope Lights Explained: Are You Wiring Your Project for Failure?

You have landed a lucrative commercial lighting contract, the design is approved, and the budget is set. But when the shipment arrives, the installation team calls you in a panic: "This strip has five wires, but the controller only has two ports." In the world of LED lighting, counting wires isn’t just about math—it’s about functionality.

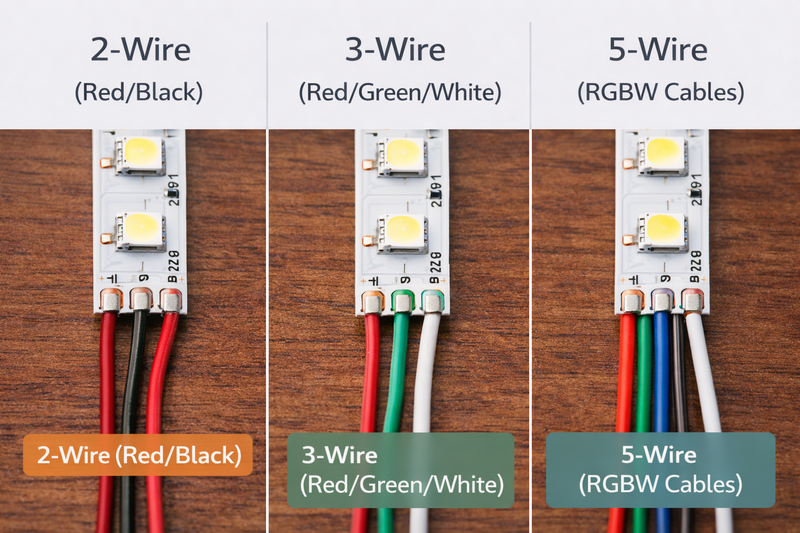

The number of wires on an LED strip dictates its control capabilities. A 2-wire system is for simple static single-color lighting; a 3-wire system typically enables dynamic addressable (IC) effects; and a 5-wire system powers complex RGBW color mixing requiring a dedicated white channel. Choosing the wrong wire configuration means either paying for features you can’t use or missing out on the effects your client demanded.

As a factory owner who has exported containers of LED strips to the US and Japan, I’ve seen this confusion derail projects constantly. Contractors often assume "more wires equals better," but that’s false. More wires equal more complexity. Let’s break down exactly what these wires do, so you can order the right product for your specific application and avoid embarrassing installation delays.

Why Is the 2-Wire System the "Workhorse" of Commercial Lighting?

In 80% of architectural projects—cove lighting in hotels, cabinet lighting in kitchens, or retail shelf displays—you don’t need fancy colors. You need reliability. This is where the 2-wire system dominates.

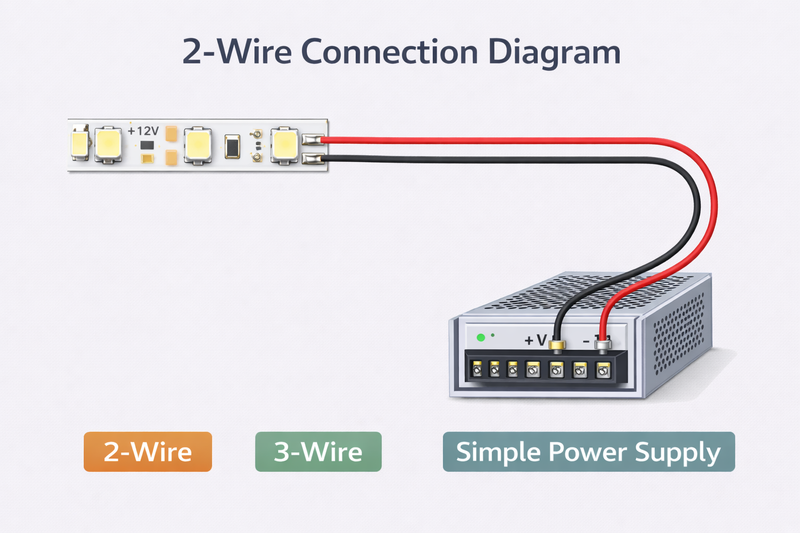

A 2-wire configuration (Positive and Negative) is the standard for static single-color LED strips. It offers the simplest installation, compatible with basic dimmers and power supplies, making it the most cost-effective and failure-proof solution for general ambient lighting where color changing is not required.

Simplicity Equals Reliability

When you see two wires—usually Red (+) and Black or White (-)—you are looking at a classic single-color circuit.

The Application:

This is your standard 3000K Warm White or 6000K Cool White strip.

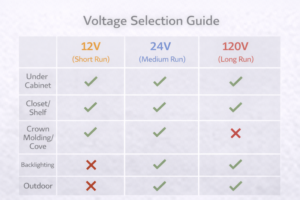

- Voltage: It works on both 12V and 24V1 systems.

- Function: It only does two things: Turn On and Turn Off. (And Dim, if you have a dimmable driver).

Why Professionals Love It:

- Lower Labor Cost: Your electrician doesn’t need a degree in DMX programming to install this. Connect Red to Red, Black to Black, and you are done.

- Longer Runs: Because the circuit is simple, we can use thick copper PCBs to minimize voltage drop. For example, our 24V single-color strips can run up to 10-15 meters on one side power feed without dimming at the end.

- High Density Options: Our 2-wire COB strips can pack 480 LEDs per meter2. Since we don’t need space for complex signal lines on the PCB, we can dedicate all the board space to LED chips and heat dissipation. This results in that seamless "neon" look that luxury hotels demand.

Factory Specs:

In our catalog, you will see 2-wire products listed with simple cut points. For a 12V COB strip, the cutting length can be as precise as 10mm or 25mm . This allows for incredible precision in joinery work.

What Is the "Mystery Wire" in a 3-Wire System?

You want movement. You want the lights to "chase" down the hallway or flow like water around a bar. A standard 2-wire strip can’t do this. A standard 4-wire RGB strip can’t do this. You need the 3-wire digital magic.

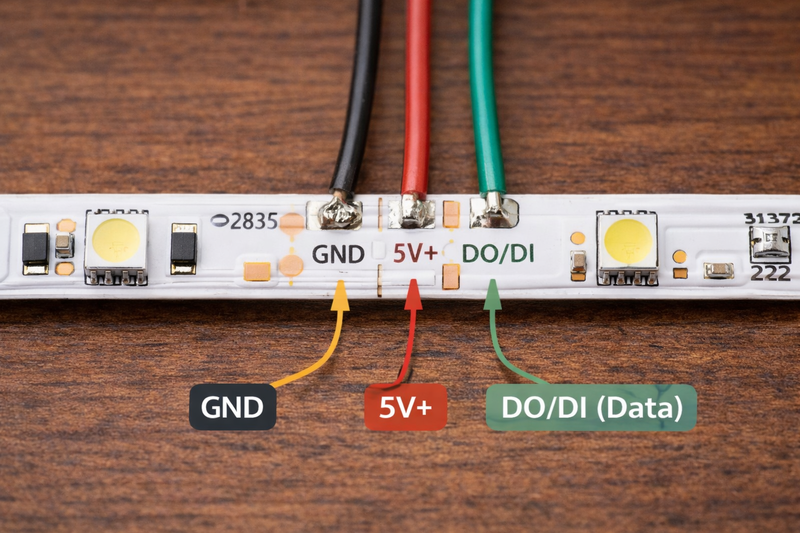

A 3-wire configuration generally indicates an Addressable (IC) LED strip, often labeled as "Magic Color" or "Pixel" tape. The wires represent Positive (+), Negative (-), and Data (DAT). This extra Data wire sends digital instructions to individual chips, enabling dynamic effects like running water, meteor trails, and complex gradients.

The Data Channel Revolution

This is where things get technical, and where many buyers get confused.

The Configuration:

A typical 3-wire Setup usually involves:

- 5V+ or 12V+: Power

- GND: Ground

- DO / DI: Data Out / Data In.

How It Works:

Unlike a standard strip where the whole roll turns on at once, a 3-wire RGB+IC3 strip communicates with specific sections of the strip.

- In our catalog, you will see specs like "Magic Color Chasing Lights" or HC-05-5-S01160-RGB+IC.

- The "IC" stands for Integrated Circuit. This chip listens to the controller via the Data wire. You can tell pixel to be Red and pixel to be Blue simultaneously.

The "Phantom" 3-Wire (Tunable White):

Note: Occasionally, a 3-wire strip can be Dynamic Tunable White (CCT)4.

- Wire 1: Positive (+)

- Wire 2: Warm White Negative (-)

- Wire 3: Cool White Negative (-)

- This allows you to mix the two channels to adjust color temperature from 2700K to 6500K. However, in the modern market, digital addressable (Data) is the most common use for the 3-wire format.

Installation Warning:

These strips represent a "Logical" installation, not just electrical.

- Direction Matters: You must connect the signal to the "Input" (DI) end. If you connect to the "Output" (DO) end, nothing happens.

- Cutting Precision: Our factory offers ultra-precise cutting lengths for these 3-wire strips, such as 12.5mm or 20mm, which is critical for making custom neon signs where the animation needs to flow smoothly to the very edge of the letter.

Why Do You Need 5 Wires for True Color Mixing?

Standard RGB lights (4-wire) create a pathetic, bluish "fake white" when you turn all colors on. If your client is a high-end restaurant or jewelry store, they will hate it. They want rich colors and a pure, crisp white.

A 5-wire system is used for RGBW (Red, Green, Blue, + White) LED strips. The fifth wire controls a dedicated white diode (either Warm or Cool White). This allows you to produce vibrant saturated colors for party modes, but switch to a clean, high-CRI white for general cleaning or daylight tasks, offering the best of both worlds.

RGBW – The Commercial Standard

For years, we sold 4-wire RGB strips. They are great for nightclubs, but terrible for illumination. Mixing Red+Green+Blue creates a light that looks white but has a terrible Color Rendering Index (CRI)5. It makes skin look grey and food look unappetizing.

The 5-Wire Breakdown:

- + (Positive 12V/24V)

- R (Red channel)

- G (Green channel)

- B (Blue channel)

- W (White channel).

Why "W" Matters:

In our catalog, these are often labeled as RGBW or RGB+W.

- Versatility: A hotel bar can use the "W" (3000K Warm White) during the day for a cozy coffee atmosphere. At night, they dim the "W" and bring up the "RGB" for a purple lounge vibe.

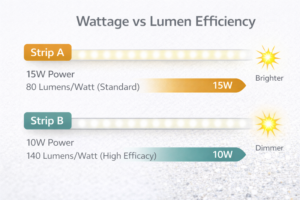

- Power Consumption: Running the dedicated White chip is more energy-efficient than running R, G, and B at 100% to try and create white.

Controller Compatibility:

This is the biggest pain point. You cannot hook a 5-wire strip into a standard 4-wire RGB controller. You need a dedicated RGBW controller6. If you try to jam the wires in, you will either lose the white channel or short the system.

The "6-Wire" Variant (RGBCCT):

Just to complicate things, there is also a 6-Wire version (RGBCCT), which has RGB + Warm White + Cool White. But for most commercial applications, the 5-Wire RGBW is the sweet spot between cost and functionality.

How Does "Board Width" Limit Your Wire Choice?

You might want a 5-wire RGBW strip, but your architect has designed a tiny, thin shelf groove. Can you physically fit a 5-wire strip into a narrow space? Usually, the answer is no.

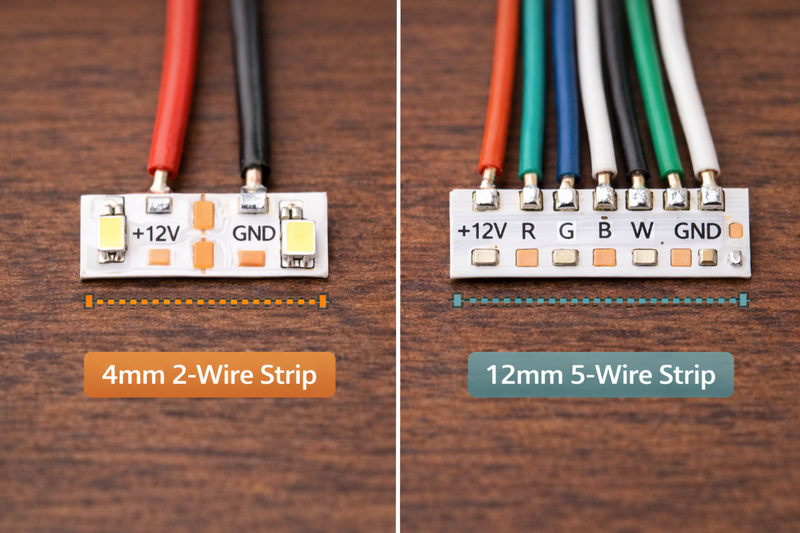

The number of wires directly influences the PCB (Printed Circuit Board) width. While 2-wire strips can be manufactured as narrow as 2.7mm or 4mm for ultra-slim joinery, multi-channel 5-wire strips require wider boards (typically 10mm or 12mm) to accommodate the extra copper tracks and larger soldering pads.

Physics vs. Design

As a manufacturer, I have to balance the electrical requirements with physical space.

The 2-Wire Nano Advantage:

Because we only need two tracks (Positive and Negative), we can shrink the board significantly.

- We produce 2-wire COB strips7 with a width of just 4mm or even 2.7mm.

- This is perfect for embedding lighting into glass shelves or intricate millwork where the fixture must be invisible.

The 5-Wire Limitation:

- To run 5 parallel circuits plus the LEDs, we need physical width.

- Most RGBW (5-wire)8 strips in our catalog are 12mm wide .

- Standard RGB (4-wire) strips are usually 10mm wide.

The Decision Matrix:

If your customer says, "I want RGBW color changing in this 5mm wide groove," you have to tell them it’s impossible. You cannot fit a 12mm wide 5-wire strip into a 5mm slot.

- Solution: You must switch them to a 2-wire single color strip (which fits) or redesign the joinery to accept a wider profile.

Connection Complexity:

Soldering 5 wires onto a 12mm board is manageable. Soldering 5 wires onto a 4mm board would be a nightmare and prone to short-circuiting. That is why high-wire-count strips will always be wider.

Conclusion

The number of wires is not just a technical detail; it is the DNA of your lighting system.

- Choose 2-Wire for reliability, thin profiles (2.7mm-4mm), and static white light.

- Choose 3-Wire when you need digital "Magic Color" chasing effects.

- Choose 5-Wire when you need professional RGBW color mixing with a dedicated white channel.

By matching the wire count to the project’s actual needs, you save money on controllers, reduce installation errors, and deliver a lighting effect that actually works.

-

Understanding the differences can help you choose the right LED system for your needs. ↩

-

Discover how high-density LED strips can enhance your lighting design and efficiency. ↩

-

Understanding RGB+IC technology is crucial for optimizing your LED strip lighting projects. ↩

-

Explore how Dynamic Tunable White can enhance your lighting design with adjustable color temperatures. ↩

-

Understanding CRI is crucial for selecting lighting that enhances colors accurately, making it essential for various applications. ↩

-

Exploring RGBW controllers will help you understand their importance in managing lighting systems effectively. ↩

-

Explore the advantages of 2-wire COB strips for compact lighting solutions, perfect for discreet installations. ↩

-

Learn about RGBW (5-wire) technology to understand its applications and limitations in modern lighting. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting…

IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…