Energy-Efficient Holiday Lighting with LED Rope Lights: Are Compounding Energy Costs Eating Your Profits?

Every January, commercial property managers and homeowners alike open their electricity bills and gasp. The cost of running extensive holiday displays for six weeks can be staggering, especially if the installation relies on outdated incandescent bulbs or inefficient first-generation LEDs. If you are a lighting contractor or distributor, you know that "energy efficiency" isn’t just a buzzword—it is the closing argument that wins you the contract.

To deliver truly energy-efficient holiday lighting solutions that do not compromise on brightness, you must transition to High-Luminous Efficiency COB LED Neon systems. By utilizing 24V DC configurations with varying efficiencies between 100-140 Lumens per Watt and specific double-sided copper PCB designs, you can reduce amperage draw significantly while maintaining the high-impact, seamless glow required for commercial displays.

In my factory, we don’t just measure brightness; we measure the ratio of light to power. We are seeing a massive shift in the US market where large-scale municipal and commercial projects are demanding specific efficacy ratings to meet green energy standards. Let’s explore how you can engineer the waste out of your holiday lighting projects.

Efficiency isn’t just about picking a "green" product; it is about understanding the physics of voltage, heat, and lumen output. When you master these variables, you can install longer runs with fewer power supplies, reducing both hardware costs and operational expenses for your clients.

Why Is Lumen Efficiency the Metric You Cannot Ignore?

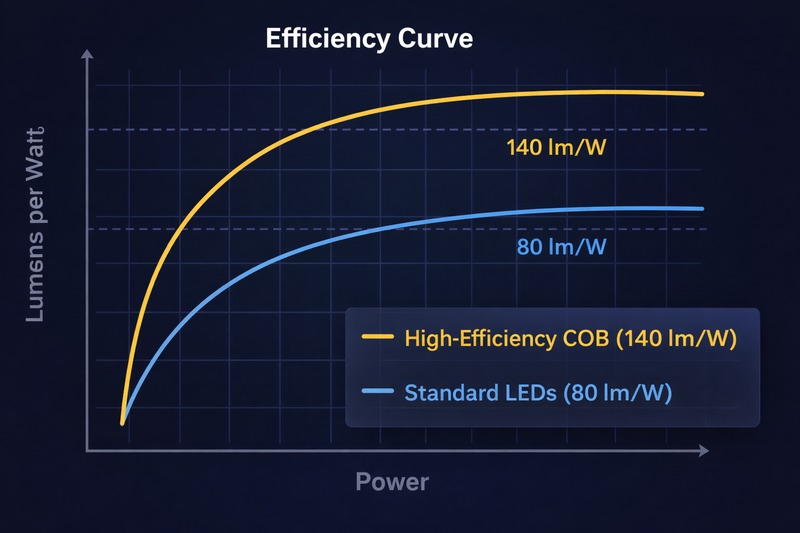

Most buyers look at "Watts per Meter" and assume lower is better. This is a mistake. A low-wattage strip might just be dim. The real metric is Lumens per Watt (Lm/W)—how much light are you getting for every unit of energy paid for?

You need to source LED strips that deliver high efficiency, ideally between 110 Lm/W and 140 Lm/W. Our latest COB technology achieves up to 140 Lumens per Watt at specific color temperatures (like 5000K), meaning you can light up a massive building facade using a fraction of the power required by standard 80 Lm/W strips.

The Economics of Efficiency

When bidding on a commercial shopping mall or city center project, the operating cost is often part of the proposal.

The Efficiency Hierarchy:

- Standard LEDs: Average around 80-90 Lm/W.

- High-End COB1: Our data shows specific efficiency tiers based on color temperature.

- Warm White (3000K): Operates around 110-120 Lm/W. This gives you that cozy, traditional holiday gold look without the heat of incandescent bulbs.

- Cool White (5000K): Can reach peaks of 130-140 Lm/W. This is incredibly efficient.

- The Math: If a project requires 100,000 lumens of light:

- Standard Strip (80lm/W): Requires 1,250 Watts.

- High-Efficacy Strip (130lm/W): Requires only 769 Watts.

- Result: That is a 38% reduction in power consumption instantly.

Heat Management:

Efficiency equals less heat. Energy that doesn’t become light becomes heat.

- Inefficient strips get hot, degrade the silicone housing, and turn yellow.

- Our IP67 480 LEDs/m strips run cool because they convert more energy into visible light . This extends the lifespan beyond 36,000 hours, meaning you aren’t replacing the installation in two years.

Voltage Impact:

Using 24V DC2 allows for lower current (Amps) compared to 12V for the same wattage.

- Lower amperage means less energy lost as heat resistance in the copper wires over long distances.

- Our 24V systems support longer runs (up to 10 meters) with stable current, further improving total system efficiency.

How Does "No Dark Area" Technology Reduce Waste?

In traditional rope lights, LEDs are spaced far apart. To get a "continuous" line of light, installers often have to overdrive the brightness (waste energy) to blind the eye into not seeing the gaps.

Switch to High-Density COB (Chip on Board) strips with 320 to 512 LEDs per meter. Because these chips create a solid, uniform phosphor line with "no dark areas" at lower brightness levels, you can actually run them at lower power settings while still achieving a visually superior, solid-neon look compared to over-driven SMD strips.

Optical Efficiency vs. Electrical Efficiency

It sounds counterintuitive, but a "brighter" looking light often uses less power if the optics are better.

The "Dot" Problem:

- Old Tech: To make a distinct "dot" light look like a line, you need diffusers that block light (absorbing 30-40% of the output) or you have to crank the power up.

- New Tech (COB): With 480 LEDs per meter or 512 LEDs per meter, the spacing is essentially zero.

- High Light Transmittance: Our COB strips feature "high light transmittance3" silicone . Because the light source is already uniform, we don’t need heavy, milky diffusers that eat up lumens. The light escapes freely.

Soft Light Advantage:

- Holiday lighting is atmospheric. The goal is "Soft Light", not industrial floodlighting.

- COB strips provide a wide 180-degree emitting angle . This spreads the light effective across the viewing surface.

- Because the light is soft and uniform, you can use a dimmer. Running an LED at 80% brightness creates a barely noticeable visual difference but drastically reduces heat and power consumption, exponentially extending the life of the double-sided copper PCB4 .

| Feature | Standard Rope Light | High-Density COB |

|---|---|---|

| LED Spacing | Large Gaps (Dots) | Zero Spacing (Line) |

| Required Brightness | High (to hide gaps) | Moderate (naturally uniform) |

| View Angle | 120 Degrees | 180 Degrees |

| Visual Effect | Pixelated | No Dark Areas |

Can You Save Energy with Precision Cutting?

Waste comes in many forms. Physical waste—cutting a 5-meter roll and throwing away 1 meter because you couldn’t cut it to fit—is also a waste of embedded energy and money.

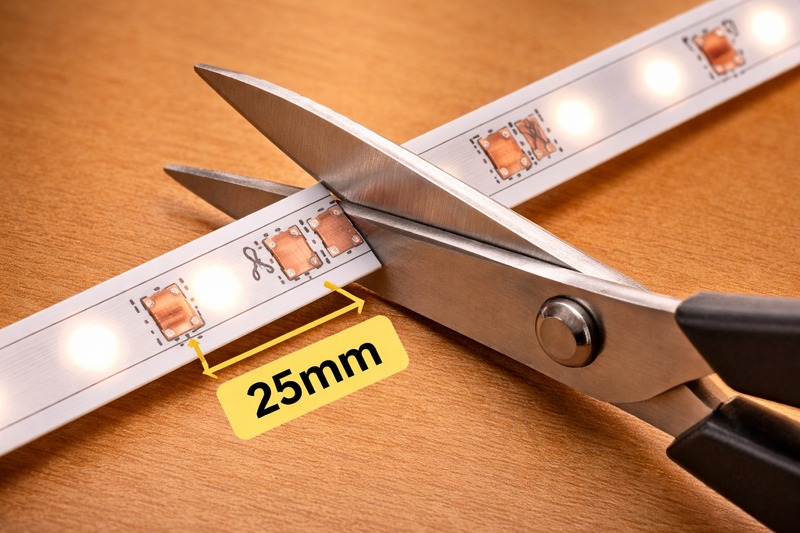

Utilize the specific "Short-Cut" capabilities of 12V and 24V COB systems. By selecting voltage platforms that allow for cut lengths as short as 10mm to 50mm, you can tailor the lighting exactly to the architectural features, ensuring you are only powering the exact length of light needed for the display, with zero electrical overlap or physical waste.

The Geometry of Savings

In a large commercial install involving hundreds of rooflines and windows, "overrun" adds up.

The Cutting Unit Math:

- 12V Systems: Our 12V COB strips often feature a cutting unit of 25mm (approx 1 inch).

- 24V Systems: Typically 50mm (approx 2 inches).

- The Scenario: You have a window frame that is 102cm wide.

- Old Strip (10cm cut point): You cut at 110cm and hide 8cm of lit strip behind the wall (wasting power) or fold it back (risk of damage).

- COB Strip (2.5cm cut point): You cut at exactly 102.5cm. You are only powering what is seen.

Voltage Scaling:

- While 12V offers tighter cutting precision, 24V is generally more efficient for long runs due to lower voltage drop.

- Power Injection: Inefficient systems need power injection every 5 meters. This requires extra copper wiring (which has its own resistance losses).

- Our 24V COB designs5 optimize the balance between cutting length (50mm) and run length (10 meters), minimizing the "copper loss" in your setup wires.

PCB Width:

- For delicate, low-power applications, use our 4mm PCB width strips. These are tiny, use less raw material (copper/silicone), and are perfect for low-wattage accent lines where a massive 12mm strip would be overkill in both size and energy draw.

How Do Smart Controls and "Magic Color" Reduce Consumption?

The most energy-efficient light is the one that is off—or at least, the one that isn’t running white light at 100% duty cycle constantly.

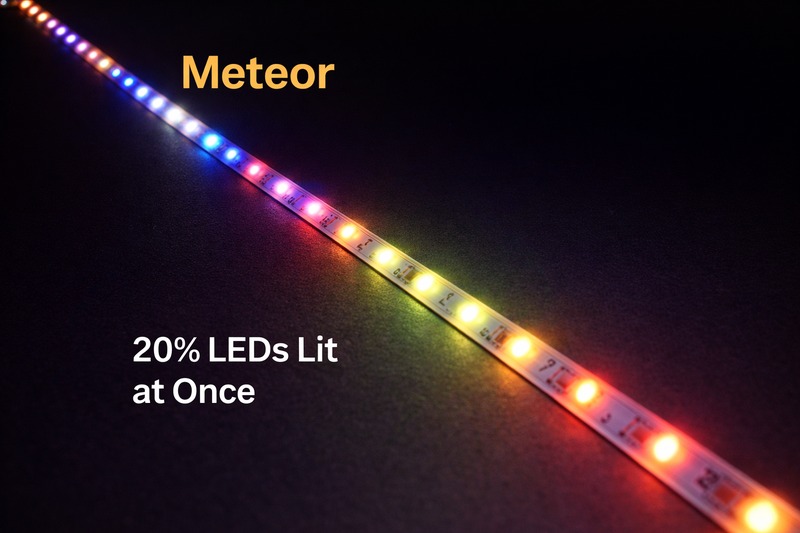

Implement "Magic Color" (RGB+IC) addressable systems. By programming dynamic scenes like "Meteor" or "Chasing," you are only illuminating a fraction of the LEDs at any given micro-second compared to a static "all-on" display. Furthermore, using smart ICs allows you to schedule dimming and color shifts that naturally consume less power than static white.

The Duty Cycle Secret

"Magic Color" isn’t just for show; it’s an energy hack.

Static vs. Dynamic Power:

- Static White: To make white on an RGB chip, Red, Green, and Blue are all ON. This is maximum power draw (e.g., 16W – 24W per meter).

- Chasing Effects: With WS2811 or Native ICs, you typically run patterns. A "Chase" pattern might have 10 pixels on, followed by 10 pixels off.

- The Result: The average power consumption6 drops by 40-60% because half the LEDs are off at any given moment.

The Technology:

- We offer 720 LEDs/m RGB+IC7 strips. This density allows for incredibly smooth motion.

- Even though the rated power is high (24W/m max), the actual usage in a dynamic mode is much lower.

- Zone Control: Use the IC addressability (pixels every 50mm or 100mm)to turn off sections of the building that aren’t visible at certain times, without needing physical switches.

Spectral Efficiency:

- Red light uses less voltage than Blue or Green. A "Candy Cane" design (Red/White) uses less power than a "Frozen" design (White/Blue). You can guide clients toward energy-efficient color palettes using the RGB+IC capabilities.

| Mode | Active LEDs | Relative Power Consumption |

|---|---|---|

| Static White (RGB Mixed) | 100% (R+G+B) | 100% (High) |

| Static Red | 33% (Red Only) | ~30% |

| Meteor Chase | ~20% (Moving) | ~20-25% (Low) |

| Breathing Effect | Variable (0-100%) | ~50% (Average) |

Does Safety Voltage Correlate with Efficiency?

Many installers assume "High Voltage" (120V) is better for long runs, but it comes with severe safety risks and regulation costs. Low voltage systems are safer and can be just as efficient if engineered correctly.

Stick to low-voltage 12V or 24V DC systems. Not only does this eliminate the risk of electric shock for public-facing holiday displays, but modern 24V bus-designs utilize double-sided copper PCBs to ensure that power is delivered efficiently to the chips without dangerous heat buildup, complying with strict IP65/IP67 waterproofing standards for outdoor energy safety.

Safety Is Efficiency

Accidents are the biggest waste of all. But beyond that, low voltage systems generally allow for better thermal control.

Thermal Runaway Prevention:

- High voltage (110V/220V) strips often use resistors that dissipate massive amounts of heat to drop the voltage for the LEDs.

- 24V Systems7: Our 24V COB strips match the forward voltage of the LED series strings more closely.

- Material Science: We use FPC with double-sided copper.

- Copper is a great conductor of both electricity and heat.

- This design minimizes "Voltage Drop" resistance heating.

- It pulls heat away from the chip, keeping the Luminous Efficiency8 high (remember, hot LEDs are dim/inefficient LEDs).

Waterproofing and Insulation:

- Energy is wasted when water creates short circuits.

- We offer IP67 (Hollow Extrusion) and IP68 (Solid Extrusion).

- Solid Silicone: Fully encases the strip. It provides thermal mass to soak up heat and prevents any leakage current that would trip expensive GFCI breakers.

- Sealing: Proper sealing with our end caps is vital. A short circuit is 100% waste (and a fire hazard).

Amperage Management:

- While 12V is great for small lengths, 24V is the commercial standard.

- Halving the amperage (by doubling voltage from 12 to 24) reduces the $I^2R$ losses (power lost to resistance) by a factor of 4. This is basic physics that saves you money on every foot of wire.

Conclusion

Energy-efficient holiday lighting is no longer just about buying "LEDs" and hoping for the best. It requires specific sourcing and engineering. By selecting High Efficacy COB Strips (up to 140 Lm/W) to get more light for less power, utilizing 24V Double-Sided Copper PCBs for efficient transmission, leveraging "No Dark Area" optics to lower required brightness, and using Magic Color (RGB+IC) to reduce duty cycles, you can slash operation costs. Don’t let the utility company take your holiday profits; engineer your display for efficiency.

-

Explore the advantages of High-End COB lighting for efficiency and cost savings in your projects. ↩

-

Learn how 24V DC systems enhance efficiency and reduce energy loss in lighting installations. ↩

-

Understanding high light transmittance can help you choose more efficient lighting solutions that save energy and enhance brightness. ↩

-

Exploring the advantages of double-sided copper PCBs can provide insights into improved thermal management and longevity of LED lights. ↩

-

Explore this link to understand how 24V COB designs can enhance efficiency and reduce energy loss in your lighting projects. ↩

-

Learn about power consumption in LED lighting to optimize energy use and reduce costs. ↩

-

Explore this link to understand how 24V systems enhance efficiency and reduce energy waste in LED applications. ↩ ↩

-

Learn about the impact of temperature on luminous efficiency to optimize your LED performance and energy savings. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

Event and Wedding LED Rope Lighting: Are Your Lights Ruining the “Big Day”?

Picture the scene: A bride spent thousands on her floral arrangements. The photographer is lined up for the perfect shot.…

Retail Display LED Rope Lighting: Is Your Lighting Scaring Away Customers?

We have all had that experience: walking into a retail store where the lighting feels harsh, clinical, or uneven. The…

Restaurant and Bar LED Rope Lighting Design Ideas: Is Your Ambience Killing Your Profits?

It is the oldest rule in the hospitality playbook: people don’t just pay for the food; they pay for the…