Fence and Railing LED Rope Light Installation Ideas: How to Achieve a Premium Linear Glow?

You invest thousands in cedar fencing, glass balustrades, or custom ironwork, yet at night, your perimeter disappears into the black void. Most contractors slap on cheap solar post caps that cast a weak, blueish glow, ruining the aesthetic you worked so hard to build.

To truly elevate your hardscape, you must integrate high-density linear LED lighting directly into the rail or fence structure. By utilizing narrow PCB COB strips with IP67 hollow silicone extrusion, you create a seamless, "dot-free" line of light that hides within the architecture, providing safety and ambiance without the visual clutter of bulky fixtures.

In my years exporting to the US market, I have seen too many high-end decks ruined by "spotty" lighting. When the light source is at eye level—like on a banister or fence top—imperfections are unforgiving. Let’s explore the professional methods for illuminating these challenging linear structures.

Why Is "Dot-Free" COB Technology Essential for Handrails?

When you install a light strip under a handrail, the LEDs are often reflected on the glass below or are visible when walking up the stairs. Standard LED tape creates a "polka dot" reflection that looks cheap and unfinished.

You must switch to COB (Chip on Board) technology for any application where the strip is visible or close to a reflective surface. With densities reaching 512 LEDs per meter, COB strips eliminate dark spots entirely, creating a fluid, solid ribbon of light that mimics neon, ensuring your railing looks like a cohesive architectural element.

The Science of High Density

In the past, we relied on SMD5050 chips which had gaps between them. Even with a diffuser, you could see the "hot spots." For a fence or railing, this is unacceptable because the eye is drawn to the anomaly rather than the path.

The COB Revolution:

In our factory, we manufacture COB strips that mount the chips directly to the circuit board.

- Zero Glare: We produce models with 320, 480, and even 512 LEDs per meter. Despite this incredible density, the light is soft.

- Reflective Surfaces: If you are lighting a glass railing or a stainless steel cable railing, this is non-negotiable. An old-school strip will look like a string of Christmas lights reflecting off the metal. A COB strip looks like a solid laser beam.

- Cutting Precision: Railings are precise. You cannot have 4 inches of darkness at the end of a handrail. Our COB strips offer cut points as small as 50mm (2 inches) or even 25mm (1 inch) on specific voltage models. This allows you to trim the light exactly to the post, maintaining a custom-fitted look.

Technical Installation Constraint:

While COB is flexible, it has limits. Our engineering data emphasizes a bending diameter of R > 15mm. When installing on a fence corner, do not force the strip into a sharp 90-degree crease. This will snap the internal circuitry. Instead, use a "soft corner" technique or a corner connector to bridge the gap.

| Feature | Standard Strip | High-Density COB | Benefit |

|---|---|---|---|

| LED Density | 60 – 120 LEDs/m | 480 – 512 LEDs/m | No visible dots, perfect uniformity |

| Reflection | Distinct "beads" | Solid Line | Premium look on glass/metal |

| Cut Length1 | Every 4-6 inches | Every 1-2 inches | Fits railing length perfectly |

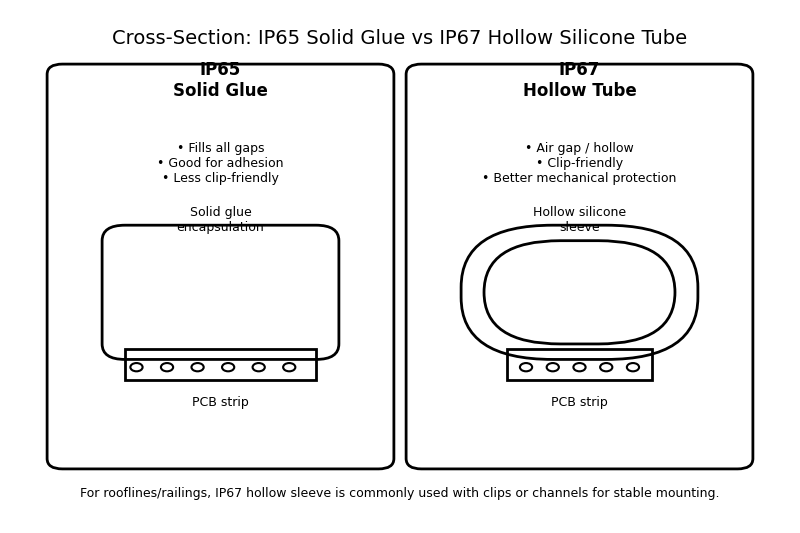

Why IP67 Hollow Extrusion Beats IP65 Glue for Outdoor Rails?

Fences and railings are exposed to the harshest elements: freezing rain, baking UV rays, and direct hose water. Choosing the wrong waterproof rating is the number one reason for failure within six months.

Avoid IP65 "glue-dropped" strips for permanent outdoor installs; they yellow and crack under UV exposure. Instead, specify IP67 Hollow Silicone Extrusion. This technology uses a clear silicone sleeve that protects the LEDs from humidity and rain while allowing the strip to "breathe" thermally, preventing overheating inside narrow railing channels.

The Material Battle

I often have to correct US buyers who think "IP65 is good enough" because it is cheaper. For an indoor kitchen cabinet, yes. For a $50,000 deck project? Absolutely not.

The Problem with IP65 (Glue/Potting):

IP65 usually involves dropping a layer of epoxy or silicone glue on top of the PCB.

- Thermal Expansion: The metal railing heats up in the sun. The strip expands. The glue hardens and cracks over time, letting water touch the chips.

- Discoloration: The potting compound often turns yellow/brown after one summer of UV radiation, altering your light color from a crisp white to a dirty urine color.

The Solution: IP67 Hollow Extrusion2:

We manufacture a rectangular silicone tube that surrounds the LED tape.

- Lightweight: Unlike IP68 (which is filled solid), IP67 hollow is lighter. This is crucial when adhering a strip upside down under a handrail. Heavy strips invariably fall off when the adhesive gets warm.

- Thermal Management3: The air gap inside the hollow tube acts as a buffer. It allows the high-power LEDs (often 10W-15W per meter) to dissipate heat more effectively than if they were suffocated in solid glue.

- Protection: It handles rain and splashes perfectly. Unless you plan to submerge your fence in a swimming pool (which requires IP68), IP67 is the superior engineering choice for railings.

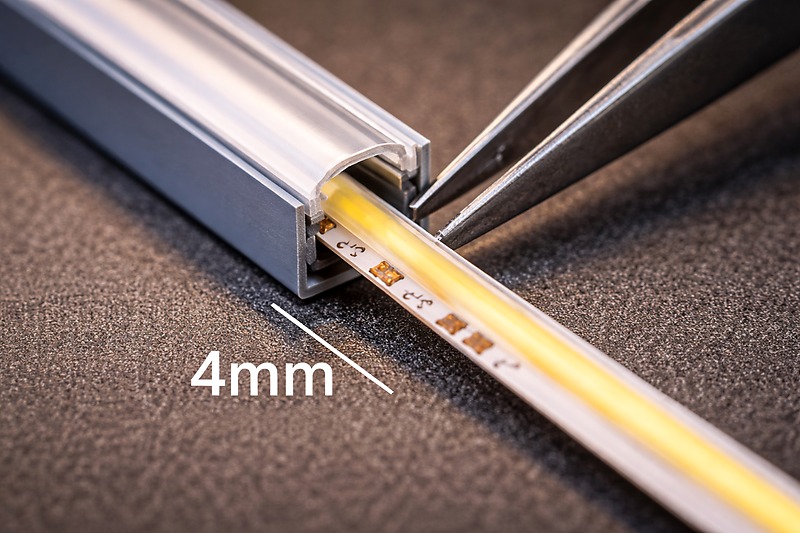

Can You Hide Lights in Thin Metal Railings?

Modern aluminum and steel railing systems are sleek and minimalist. They often feature undersized channels that cannot accommodate a standard 10mm or 12mm wide LED strip. Installing a bulky strip ruins the profile.

Source "Nano" or Narrow-PCB COB strips designed specifically for architectural slots. We manufacture ultra-slim waterproof options with PCB widths as narrow as 4mm or 5mm, allowing high-output lighting to fit seamlessly into the tightest railing grooves without compromising waterproof integrity.

Dimensions Matter

Standard LED strips are 10mm or 12mm wide. When you add a waterproof sleeve, they become 12mm or 14mm. Many custom iron handrails or pre-fabricated aluminum extrusions creates channels that are only 6mm to 8mm wide.

The "Invisible" Solution:

We produce specialized 4mm and 5mm width4 strips for this exact problem.

- The 4mm COB: This is a game-changer for fabricators. Even with an IP67 waterproof sleeve, the total width remains under 6mm. You can route a tiny channel in the bottom of a wood handrail or use existing channels in aluminum systems.

- No Compromise on Power: You might think a thinner strip means less light. Not necessarily. Our narrow series still pushes out significant lumens, ensuring the pathway is lit, not just marked.

- Installation Tip: When working with these narrow strips, be extremely careful with connectors. The solder pads are tiny. I always recommend ordering these with factory-soldered leads at the exact lengths you need to avoid trying to solder 4mm wide pads on a windy job site.

Warning on Sourcing:

If you search generically, you will find "narrow strips" that are not waterproof (IP20). You must specifically verify that the factory can produce the 4mm width in an IP67 grade5, often achieved through a very specialized thin-wall silicone extrusion.

| Strip Type | PCB Width | Waterproof Width | Fits Standard Rail? | Fits Slim Rail? |

|---|---|---|---|---|

| Standard 5050 | 10mm | ~12.5mm | Yes | No |

| Standard COB | 8mm | ~10mm | Yes | Tight |

| Nano COB | 4mm / 5mm | ~6mm | Yes | Perfect Fit |

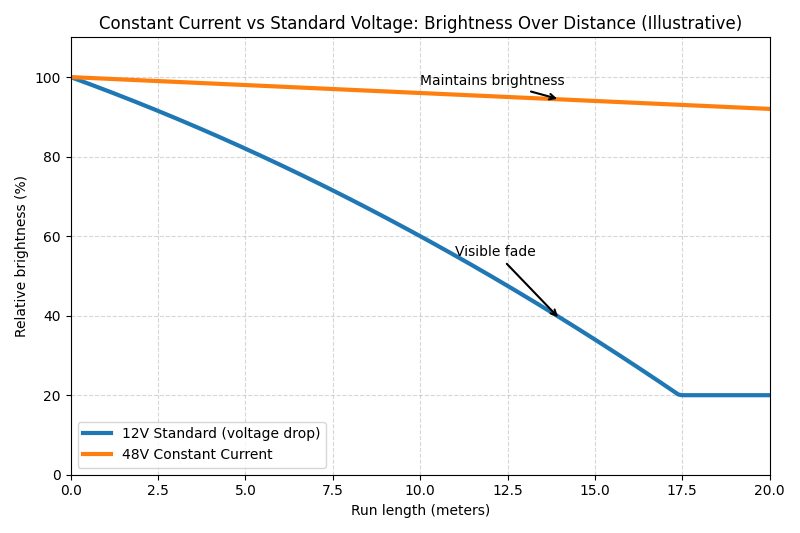

How Do You Handle Voltage Drop on Long Perimeter Fences?

A backyard fence can easily run 100 feet or more. If you use standard 12V LED tape, the light will look bright at the power source and dim to a dull orange at the far end. Running 120V mains voltage is dangerous and requires expensive conduit.

Utilize 24V Constant Current (CC) LED strips for perimeter runs. Unlike standard resistors, Constant Current IC chips ensure uniform brightness across ultra-long runs—up to 20 or 30 meters (65-100 feet) from a single power feed—reducing the need for complex trenching and multiple power supplies.

The Wiring Nightmare Solver

Nobody wants to dig a ditch. If you use standard low-voltage strips, you technically need to inject power every 16 feet (5 meters). For a 100-foot fence, that means running a thick parallel main wire and splicing into the strip 6 times. It’s labor-intensive and prone to failure points.

The Constant Current Architecture6:

We engineer distinct "Long Run" strips.

- Extended Lengths: We can supply reels of 15 meters, 20 meters, or even 30 meters (approx 100 ft).

- Visual Uniformity: A built-in IC chip regulates the current at every LED group. The first LED and the last LED (100 feet away) have the exact same brightness.

- Efficiency: Higher voltage systems (like 24V or even 36V/48V specialized architectural strips) suffer less from resistance.

Application Strategy:

- For the Fence: Install the power supply (driver) in the garage or a waterproof box near the house. Run a single low-voltage cable to the start of the fence. Run the 30m Constant Current strip along the rail. Done.

- Power Calculation: Be careful. A 30-meter run at 10W per meter is 300 Watts. You need a hefty, high-quality waterproof power supply (like a Mean Well HLG series) to handle that load confidently without overheating.

Pro-Tip: Standard voltage (like 12V) is fine for short stair railings (3-4 feet). But for anything wrapping around a deck or property line, 24V Constant Current7 is the only professional choice.

Which Color Temperature Matches Your Material?

Lighting a redwood fence is different from lighting a glass and steel balcony. The wrong color temperature can make wood look gray or steel look rusty.

Match your Kelvin rating to the architectural material. Use 2700K-3000K Warm White to enhance the rich grain of timber and stone, use 4000K Natural White for glass and grey composites, or choose RGB+IC "Chasing" strips for commercial bars and entertainment zones.

The Aesthetics of Material

Light is paint. You are painting the structure with photons.

- Wood (Cedar, Redwood, Pressure Treated): You must use 2700K or 3000K. Wood has warm, red/orange undertones. If you use a cool white (6000K) light, the blue spectrum cancels out the red in the wood, making your expensive cedar fence look like dead, gray driftwood. 3000K reinforces the natural warmth.

- Modern Composites (Trex, Azek – Greys and Blacks): Warm light can make grey composite look "muddy." For modern grey decks or black aluminum railings, 4000K (Natural White)8 is the weapon of choice. It is crisp, clean, and true to color.

- Stainless Steel & Glass: These materials have no inherent color. They reflect the light source. 4000K to 6000K creates a sparkling, "diamond" effect on glass edges. 3000K can make glass look smoky or dirty.

The "Party" Option (RGB+IC):

For commercial clients (restaurants, bars) or homeowners who love to host, we offer RGB+IC (Pixel) strips.

- Magic Color: Unlike standard RGB (where the whole strip changes color at once), IC chips allow for "chasing" effects.

- Animation: You can have a "flowing water" effect running along the handrail, guiding guests toward the pool area. This is achieved with standard voltage (5V, 12V, or 24V) pixel strips.

- Warning: These require a data controller. The wiring is slightly more complex (3 or 4 wires). Ensure your controller is waterproof if located outside.

| Material | Recommended CCT | Why? |

|---|---|---|

| Wood | 2000K – 3000K | Enhances grain, warmth, and richness |

| Grey Composite | 4000K | Keeps the grey clean, avoids muddy look |

| Glass / Steel | 4000K – 6000K | Maximizes sparkle and modern feel |

| Commercial Bar | RGB+IC | Dynamic movement, branding colors |

Conclusion

Your fence and railing lighting should be felt, not seen. By moving away from visible dots and standard voltages, and instead specifying High-Density COB, IP67 Hollow Silicone, Narrow PCBs for slim rails, and Constant Current for long perimeter runs, you transition from a DIY look to a professional architectural finish. Lighting is the final layer of your design—make sure it is as durable and precise as the structure itself.

-

Learn about the importance of cut length in LED strip lighting for achieving a seamless and professional finish. ↩

-

Explore this link to understand why IP67 Hollow Extrusion is a superior choice for outdoor LED applications, ensuring durability and performance. ↩

-

Learn about thermal management’s critical role in LED performance and longevity, which is essential for any lighting project. ↩

-

Explore this link to understand how 4mm and 5mm width LED strips can solve space issues while providing ample lighting. ↩

-

Learn about IP67 grade to ensure your LED strips are waterproof and suitable for various applications. ↩

-

Explore this link to understand how Constant Current Architecture enhances LED performance and efficiency. ↩

-

Discover why 24V Constant Current is the best choice for outdoor lighting applications, ensuring reliability and brightness. ↩

-

Explore how 4000K lighting enhances modern materials like composites and stainless steel, ensuring true color representation. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

Event and Wedding LED Rope Lighting: Are Your Lights Ruining the “Big Day”?

Picture the scene: A bride spent thousands on her floral arrangements. The photographer is lined up for the perfect shot.…

Retail Display LED Rope Lighting: Is Your Lighting Scaring Away Customers?

We have all had that experience: walking into a retail store where the lighting feels harsh, clinical, or uneven. The…

Restaurant and Bar LED Rope Lighting Design Ideas: Is Your Ambience Killing Your Profits?

It is the oldest rule in the hospitality playbook: people don’t just pay for the food; they pay for the…