Holiday Decorating with LED Rope Lights: All Seasons Guide – One Install, Infinite Holidays?

We have all been there. It is the first weekend of January, freezing cold, and you are standing on a shaky ladder trying to pry frozen plastic clips off your roofline. The "festive" joy of hanging Christmas lights evaporates the moment you have to take them down.

To stop this annual cycle of labor and waste, you need to transition to a permanent, all-season LED Rope Light system. By utilizing IP67 Silicone Neon Flex with RGB+IC (Magic Color) technology, you can install lighting once that serves as elegant warm white architectural lighting efficiently for 300 days a year, and transforms into dynamic seasonal colors for Christmas, Halloween, and the Fourth of July at the touch of a button.

In my role manufacturing and exporting LED solutions to the US market, the fastest-growing sector isn’t industrial lighting—it’s "Permanent Holiday Lighting." Contractors are realizing that homeowners don’t just want Christmas lights; they want a year-round asset. Let’s break down how to source the right specs to make this a reality.

Can One Light Strip Really Handle Every Season?

The biggest hesitation I hear from buyers is, "Jeremy, I don’t want my house to look like a nightclub every day." They assume that if they buy color-changing lights, they sacrifice the classy, warm look of traditional landscape lighting.

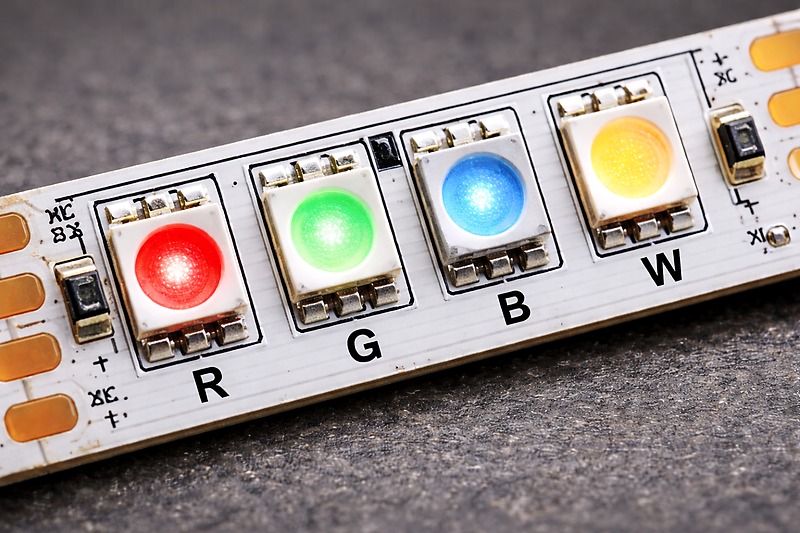

The solution is to specify RGB+W or RGB+IC strips that contain dedicated high-CRI white diodes. Unlike standard RGB strips that mix colors to create a bluish "fake" white, advanced chips (like WS2814 or specialized COB RGB) offer a pure 3000K warm white mode for daily use, ensuring your property looks sophisticated year-round until you decide to activate the "party" modes.

The Spectrum of Versatility

If you are selling a permanent solution, versatility is your primary value proposition. You are selling one hardware installation that solves five different problems.

The Architectural Mode (Daily Use):

For 10 months of the year, the lights should highlight the architecture.

- Color Temperature: You must have access to 2700K or 3000K1. Our SMD and COB data indicate that these temperatures are critical for residential warmth. Avoid 6000K for daily use unless you are lighting a commercial pharmacy.

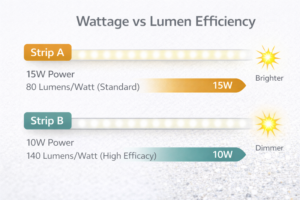

- Lumen Output: Look for efficiency. Our high-end architectural strips push 100-110 Lumens per watt. This ensures the building is securely lit without running up the electric bill.

The Holiday Mode (Seasonal Use):

This is where RGB+IC (Magic Color) comes into play.

- July 4th: You don’t just want red, white, and blue static lights. You want them to chase or flow like a flag waving. This requires IC chips (like WS2811 or UCS2904) embedded in the strip.

- Halloween: Switch the palette to Purple and Orange. With digital control, you can create "spooky" flickering effects.

- Christmas: The classic Red and Green. But with addressable LEDs, you can create a "Candy Cane" pattern where every 3rd light is white, then red, roaming around the roofline.

Sourcing Tip: When ordering, explicitly ask for "RGBW" (Red, Green, Blue + White). If you only order "RGB," your "white" setting will be a mix of all three colors, which often looks pink or blue and degrades over time.

Why Do "All-Season" Lights Often Fail After Winter?

Leaving plastic lights out year-round exposes them to the brutal combination of summer UV rays and winter freezing cycles. Standard PVC rope lights turn brittle and crack, allowing water to destroy the circuit.

You must upgrade from standard PVC or Epoxy (IP65) to IP67 Hollow Silicone Extrusion. Silicone is chemically stable and UV resistant, meaning it won’t yellow or crack in the sun, while the "hollow" design creates an air buffer that protects internal components from thermal expansion stress during freeze-thaw cycles.

Material Science for Longevity

If you install a permanent system, "permanent" needs to mean 5 to 10 years, not 9 months. The failure point is rarely the LED; it is the housing.

The "Potting" Trap (IP65):

Many cheap "outdoor" strips use a potting method—dropping a layer of glue over the LEDs.

- Yellowing: Under UV light, PU and Epoxy glues turn yellow/brown. This changes your crisp 3000K light into a dirty, muddy color within one summer.

- Thermal Stress: When the aluminum channel or gutter expands in the heat, the glue is rigid. It pulls the LED off the solder pad. Game over.

The Silicone Advantage (IP67):

We manufacture high-end ropes using food-grade silicone extrusion.

- Hollow Chamber2: Our IP67 Hollow Extrusion design places the strip inside a rectangular silicone tube without filling it solid. This air gap is crucial. It allows the heat from the high-power LEDs (often 10W-15W per meter) to dissipate properly.

- Bend Radius: The datasheets for our COB products emphasize a bending diameter of R > 15mm. Silicone allows this flexibility without snapping, unlike PVC which stiffens in the cold.

- Waterproof Integrity3: Because it is a unified sleeve, there are no seams for water to enter, provided the end caps are sealed with dielectric grease and silicone glue.

| Feature | PVC / Epoxy (Standard) | Hollow Silicone (Premium) |

|---|---|---|

| UV Resistance | Poor (Yellows/Cracks) | Excellent (Stable) |

| Low Temp Flex | Brittle < 0°C | Flexible > -40°C |

| Heat Dissipation | Trapped heat | Air Gap Cooling |

| Warranty | 1 Year | 3-5 Years |

How Do You Achieve a "Clean" Look Without Dots?

Nothing says "cheap christmas decoration" like seeing individual bright dots reflecting off a window or gutter. For a permanent architectural install, the light source must be continuous and uniform.

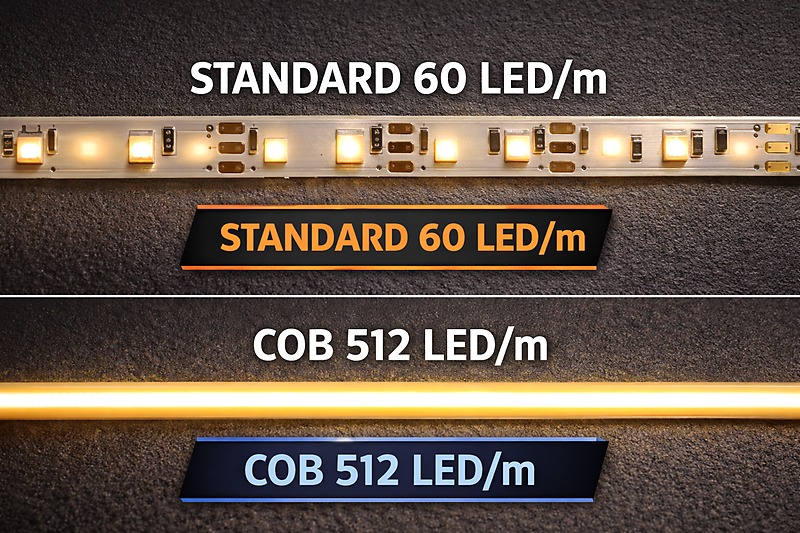

Switch to COB (Chip-On-Board) technology. With incredibly high densities of 480 or even 512 LEDs per meter, COB strips minimize the dark space between chips to effectively zero, creating a solid, laser-like line of light that mimics traditional glass neon.

The Density Revolution

In the old days of SMD5050 chips, we had 60 LEDs per meter. That is one LED every 0.65 inches. That is a lot of dark space.

The COB Spec:

Our modern COB lines rewrite the rules.

- 480 / 512 LEDs/m: We pack 512 chips into every meter4. That is virtually a continuous phosphor surface.

- No Diffuser Needed? Even without a thick milky cover, COB looks consistent. But when you put COB inside our silicone neon tube, the result is flawless. It looks like a glowing line drawn in the air.

- Reflective Surfaces: If you are installing lights under a shiny aluminum soffit or near windows, COB is non-negotiable. Standard LED dots reflect as "dots," ruining the effect. COB reflects as a smooth bar of light5.

Precision Cutting:

Another hidden benefit of high density is the cut length.

- Standard Strip: Can be cut every 4 inches (100mm). This is annoying when you reach the end of a 10-foot, 2-inch gutter.

- COB Strip: Our 24V COB strips can be cut every 50mm (2 inches), or even 25mm on specific 12V models. This allows for essentially custom tailoring on site. You can trim the light to fit the architectural features perfectly.

How Do You Handle Power for a Whole House Perimeter?

Running "All Season" lights usually means covering the entire roofline—often 100 to 200 feet. Voltage drop with standard strips is a nightmare, leading to dim, orange-tinted lights at the back of the house.

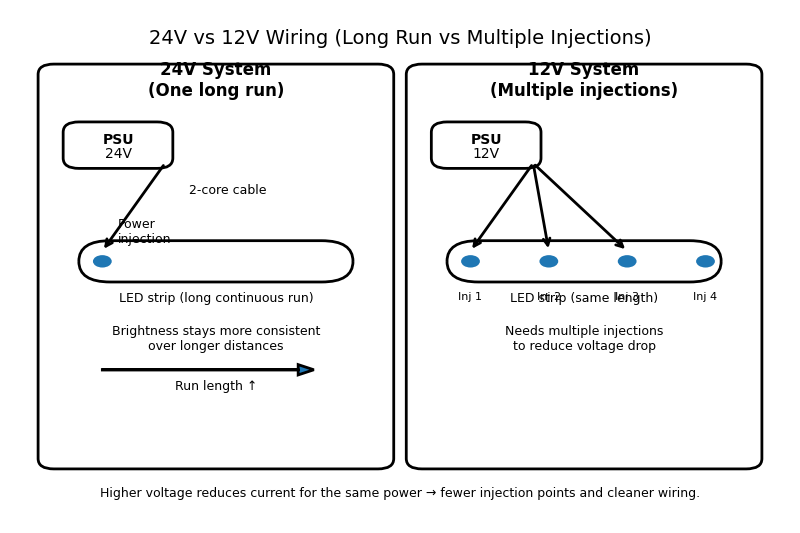

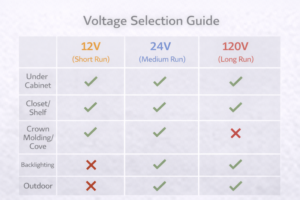

Utilize 24V Constant Current "Group Control" or High-Voltage Strips. By doubling the voltage from 12V to 24V, you reduce current/heat and can run longer lengths. For extremely large estates, explore Constant Current IC designs that ensure the first LED and the 500th LED have the exact same brightness.

The Electrical Reality

You cannot cheat physics. Voltage drop happens when electrical resistance in the copper PCB degrades the power over distance.

Why 24V is the Professional Standard:

- Run Length: A standard 12V strip might only run 5 meters (16 feet) before fading. A 24V strip6 can easily run 10 meters (33 feet) without noticeable drop.

- Current Draw: Pushing 100 Watts at 12V requires roughly 8.3 Amps. At 24V, it requires only 4.1 Amps. Lower Amps means less heat and thinner wires.

The "Group Control" Strategy:

For our addressable holiday lights (RGB+IC), we often use "Group Control" (e.g., WS2811 chip controlling 3 or 6 LEDs at once).

- Benefits: This runs on 24V directly.

- Efficiency: It is far more stable than 5V single-pixel systems.

- Effect: While you lose a tiny bit of resolution (controlling 3 inches at a time instead of 0.5 inches), for a roofline viewed from the street, nobody can tell the difference. But the installation becomes 50% easier because you need fewer power injection points.

Recommendation: For a standard suburban home, stick to 24V. Ensure your power supply (Driver)7 is sized at 120% of the total load. If your lights draw 200W, buy a 240W or 300W driver (like Mean Well HLG series) to keep it running cool for years.

Can You Install These in Narrow Channels?

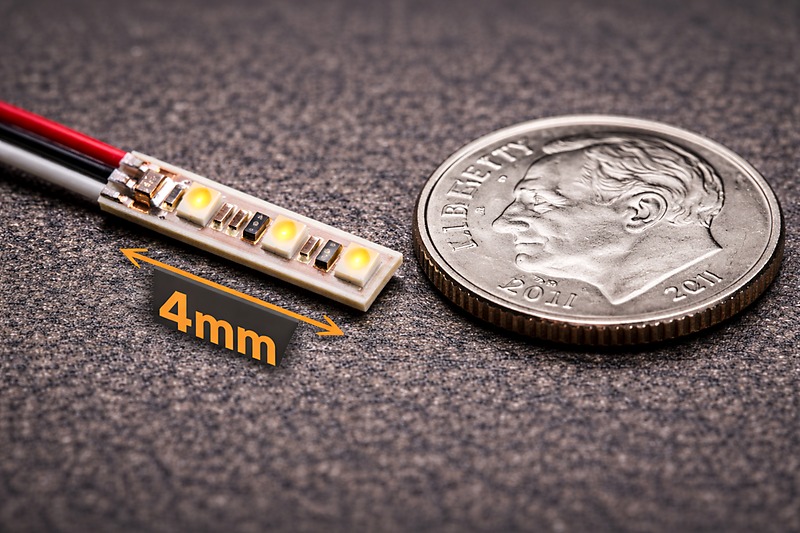

Some homeowners want the lights to be invisible during the day. This requires hiding the strips in narrow aluminum channels or fascia grooves where standard strips won’t fit.

Source "Nano" or Narrow-PCB COB strips. We manufacture waterproof IP67 strips with PCB widths as narrow as 4mm or 5mm. These ultra-slim profiles can fit into the tiniest architectural grooves, remaining completely hidden when off, but delivering full brightness when on.

Minimalist Design

The best "All Season" lighting is lighting you don’t see during the day.

The 4mm Solution:

Our catalog features 4mm PCB Width8 COB strips.

- The Fit: Standard strips are 10mm or 12mm wide (plus silicone sleeve = 14mm). Our Nano strips, even with the IP67 silicone coating, remain incredibly slim (approx 6mm total width).

- Application: These are perfect for routing into the bottom of a wooden handrail, or tucking behind the small lip of a metal gutter.

- Performance: Despite the size, they pump out significant light (often 5 Watts per meter9). They provide a subtle, elegant accent line rather than a floodlight.

Handling Warning:

Working with 4mm strips requires finesse. The solder pads are tiny.

- Order Custom Lengths: Do not try to solder these on a windy ladder. Measure your runs and order the factory to solder the lead wires for you.

- Connectors: Standard "clip-on" connectors almost never work reliably with 4mm strips. Soldered connections are the only way to guarantee a permanent, weather-tight seal.

| Strip Type | PCB Width | Total Waterproof Width | Best Use |

|---|---|---|---|

| Standard RGBW | 12mm | 14-15mm | Rooflines, large fascias |

| Standard COB | 8-10mm | 10-12mm | Under-cabinet, soffits |

| Nano COB | 4mm | ~6mm | Hidden grooves, railings |

Conclusion

The era of hanging lights in November and removing them in January is over. By strategically sourcing IP67 Silicone for weatherproofing, RGB+W/IC for hybrid daily/holiday use, High-Density COB for aesthetics, and 24V systems for manageable power runs, you create a property that is always ready to celebrate, yet elegantly illuminated every other night of the year. Invest in the infrastructure once, and enjoy the show forever.

-

Understanding the significance of these color temperatures can enhance your lighting design, ensuring warmth and comfort in residential spaces. ↩

-

Explore how a Hollow Chamber design enhances heat dissipation and longevity in LED systems. ↩

-

Learn about the importance of Waterproof Integrity in ensuring durability and performance of LED lights. ↩

-

Explore this link to understand how 512 chips enhance lighting efficiency and aesthetics in modern applications. ↩

-

Discover why COB’s smooth light reflection is crucial for achieving seamless lighting effects in various environments. ↩

-

Explore the benefits of 24V strips for lighting, including longer run lengths and reduced heat generation. ↩

-

Learn how to select the appropriate power supply for LED lights to ensure efficiency and longevity. ↩

-

Explore this link to understand how 4mm PCB Width can enhance your lighting projects with its compact design and efficiency. ↩

-

Discover why 5 Watts per meter is significant for lighting performance and how it can impact your design choices. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting…

IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…