Hotel and Hospitality LED Rope Lighting: Is Your Lighting Chasing Guests Away?

A guest walks into your hotel lobby. The design is modern, the furniture is Italian, but the cove lighting is spotting, uneven, and creates a cheap, flickering reflection on the marble floor. In that split second, their perception of your brand drops from "Luxury" to "Budget." Lighting is not just a utility in hospitality; it is the primary mood setter that justifies your room rate.

To maintain a five-star atmosphere and reduce maintenance costs, hospitality projects must transition to Dot-Free COB LED strips for seamless integration, utilize Ra90+ High CRI chips to make food and decor distinct, and mandate IP68 Solid Extrusion silicone for outdoor areas. These specs ensure the lighting disappears into the architecture while delivering a consistent, high-end experience.

As a factory owner who supplies projects from Las Vegas to Singapore, I see the same mistake repeated constantly: contractors cutting costs on the LED tape, only to spend triple that amount replacing it six months later. Let’s look at the specific manufacturing standards you need to demand to ensure your hospitality lighting survives the real world.

Why Is the "Dot-Free" Aesthetic Critical for High-End Interiors?

In the past, hotel designers had to hide LED strips deep inside coves to mask the ugly "dots" of light. But modern joinery features shallow profiles—under stair treads, inside wardrobes, and behind bathroom mirrors. There is nowhere to hide.

The industry standard has shifted to Chip-on-Board (COB) technology. With densities ranging from 320 to 512 LEDs per meter, COB strips provide a continuous phosphor coating that acts as a unified light source. This eliminates pixelation completely, allowing for installation in visible, shallow channels without needing deep diffusers.

The Engineering of "Invisible" Light

When we talk about "luxury" in lighting, we are actually talking about uniformity. The human eye is incredibly good at spotting patterns. If you use a traditional SMD 5050 strip with 60 LEDs per meter, your guest’s eye will subconsciously track the dark gaps between the light chips. This creates visual "noise."

The Density Revolution:

Our factory charts show a massive shift. Old specifications called for 60 or 120 chips per meter. Our modern COB High-Density Flexible Strips1 pack 320, 480, or even 512 LEDs per meter. Ideally, the chip gap is so small that it is invisible to the naked eye.

- Phosphor Coverage: Unlike SMD where the yellow phosphor is only on the tiny chip, COB strips cover the entire array in a continuous line of phosphor silicone. This diffuses the light at the source.

- The Result: You get a "Neon-like" effect but in a flexible, adhesive format. For a hotel reception desk made of glossy stone, this is non-negotiable. You want a smooth wash of light, not a "pearl necklace" reflection interfering with the stone’s texture.

CRI and The Restaurant Experience:

Hospitality is also about dining. Have you ever looked at a steak or a salad in a cafeteria and thought it looked unappetizing? That is often due to low CRI (Color Rendering Index).

- Standard LEDs often have a CRI of 70 or 80. They desaturate colors, making reds look brown and greens look grey.

- We manufacture our hospitality-grade strips with CRI>90 (Ra90)2. This contains the "R9" red spectrum imperative for rendering skin tones (guests look healthy) and food (meals look fresh). If your hotel restaurant charges premium prices, you cannot afford cheap, low-CRI light.

Will Your Outdoor Pool Lighting Surrey the Seasons?

Outdoor bars, pool decks, and facade lighting face the harshest lineup: UV rays, chlorinated water, and temperature swings. The most common failure I see in hotels is "waterproof" lights filling with condensation after one season.

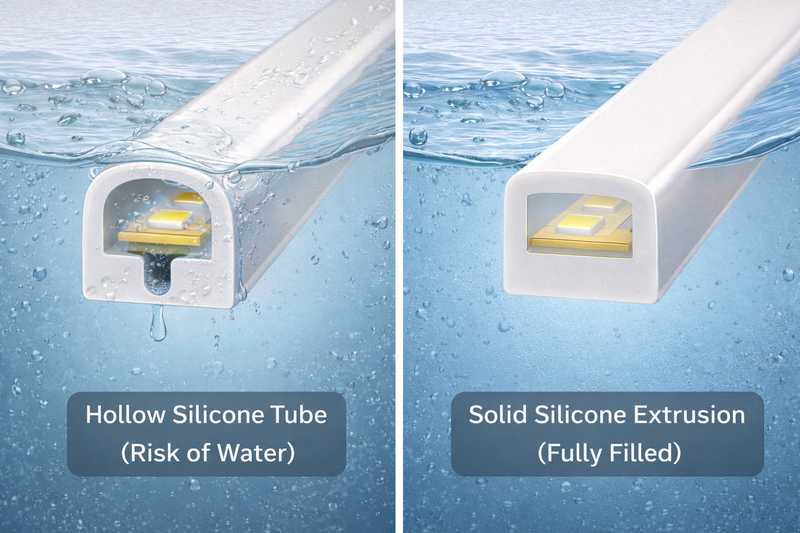

Stop specifying standard IP67 "Hollow Tube" silicone strips. For long-term reliability, you must use IP68 Solid Extrusion technology. This process completely encapsulates the LEDs and PCB in solid silicone, leaving no air gaps for condensation to form, ensuring the lights remain operational even when submerged or exposed to heavy storms.

The Physics of Condensation Failure

"Waterproof" is a tricky word on datasheets. A Certificate of Compliance might say IP67, but it doesn’t tell you how it achieved that rating.

The Hollow Tube Trap (IP67):

Many budget suppliers use a hollow silicone sleeve. They slide the LED strip inside and seal the ends with glue.

- The Failure Mode: Air is trapped inside the tube. During the day, the sun heats the air, expanding it. At night, or when cold pool water hits it, the air contracts, creating a vacuum. This vacuum sucks moisture in through microscopic gaps in the end caps. Once water is inside, it stays there, corroding the copper PCB.

The Solid Extrusion Solution (IP68)3:

Our IP68 Solid Extrusion process creates a solid brick of light.

- How it works: We co-extrude the silicone over the LED board while it is liquid. It fills every gap between the resistors and chips. There is literally zero air space inside the strip.

- Chemical Resistance: We use food-grade silicone that is resistant to yellowing from UV light and hardening from chlorine saline exposure.

- This is the only viable option for "Underwater lighting engineering" or coastal hotel balconies where salt spray is a daily reality. It costs slightly more upfront but saves thousands in labor costs because you aren’t replacing the system next year.

How Do You Light Delicate Millwork Without Bulky Fixtures?

Interior architects are pushing for minimalism. They want light coming from thin floating shelves, around mirrors, or inside narrow reveal details. Standard 10mm or 12mm wide LED strips are often too wide for these delicate applications.

The answer lies in "Nano" LED strips with ultra-narrow PCB widths of 4mm or even 2.7mm. These microscopic strips fit into routed channels that are barely wider than a saw blade, allowing millworkers to integrate lighting into furniture and architectural details where traditional lighting was previously impossible.

Thinking Small for Big Impact

In luxury hospitality design, the best lighting is the kind you don’t see. The fixture should be invisible; only the effect should remain.

The 2.7mm Breakthrough:

For years, the standard width for an LED strip was 10mm. That dictated the size of the aluminum channels (usually 14-16mm wide).

- The Problem: If a designer wants a thin, floating glass shelf or a delicate brass accent, a 16mm aluminum bar looks clunky and ruins the aesthetic.

- The Solution: Our factory produces 2.7mm COB strips4. To put that in perspective, that is the width of two credit cards stacked together.

- Application: This allows carpenters to use a simple router bit to cut a 3mm groove directly into the wood. You stick the light in, and it sits flush. No aluminum profile is needed if the wattage is managed correctly (usually roughly 5W-10W per meter allows for decent heat dissipation on wood, though metal is always preferred).

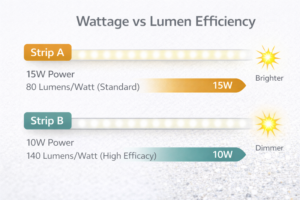

Heat and Efficiency:

You might worry that such a small strip would overheat.

- We utilize Flip-Chip technology5 for these nano strips. By removing the gold wire bonding and flipping the chip directly onto the PCB, we improve thermal transfer.

- However, for commercial hotel applications where lights run 24/7, I always advise keeping the wattage lower (around 5W or 10W) for these tiny strips or mounting them on a concealed metal heat sink tape. This ensures the "Lumen Maintenance" stays high for the 5-7 year renovation cycle typical in hotels.

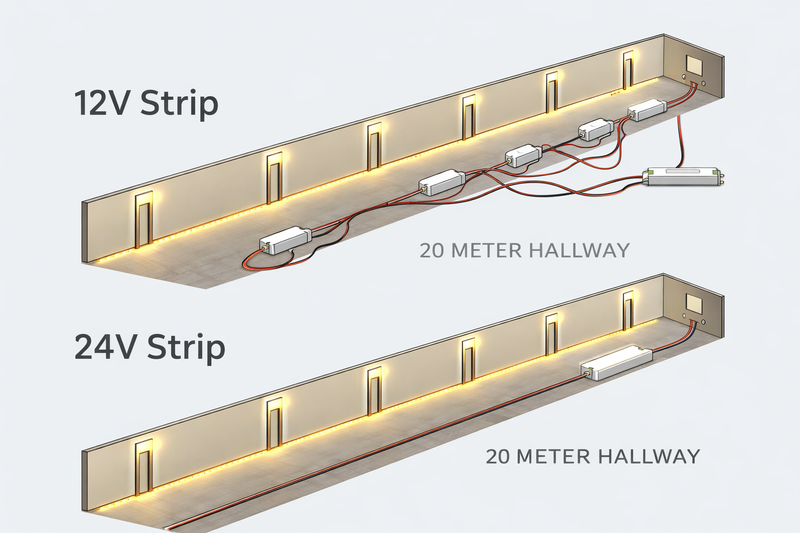

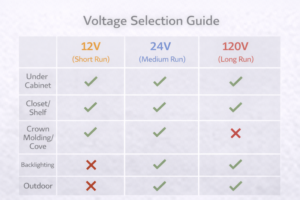

Can You Reduce Wiring Labor in Long Corridors?

Hotel corridors are notoriously difficult to light. They involve long, continuous runs of cove lighting—often 50 meters or more. Using standard 12V strips requires power injections every 5 meters, leading to a nightmare of messy cabling and transformers hidden in the ceiling.

Switch to 24V Constant Voltage or even Constant Current LED systems. By doubling the voltage, you reduce current draw, allowing for runs of 10 to 15 meters from a single power feed without visible voltage drop (dimming at the end), significantly cutting down electrician labor hours and simplifying the ceiling layout.

The Economics of Installation

As a buyer, you look at the price per meter of the strip. But your contractor looks at the "installed cost."

The Voltage Drop Problem:

- Physics: As electricity travels down a copper strip, it encounters resistance. In a 12V system, the voltage might drop to 10V after 5 meters.

- Visual Result: The start of the hallway is bright white; the end of the 5-meter section looks dim and yellow. This is unacceptable for a hotel.

- Old Fix: The electrician has to run parallel "home run" wires to inject power every 5 meters. This takes time and copper wire is expensive.

The 24V and Double PCB Advantage:

- Higher Voltage: Our 24V COB strips6 push the electricity further. You can reliably run 10 meters with one power feed.

- Double-Sided Copper: We specify 2oz or 3oz Double-Sided FPC (Flexible Printed Circuit)7 copper boards. Think of this as a wider highway for the electrons. It reduces resistance.

- Labor Savings: If a hotel has 20 floors, and each floor has a 50-meter corridor, switching from 5m runs to 10m runs cuts the number of required power soldering points in half. That saves hundreds of hours of labor across the whole project.

Consistency is Key:

Furthermore, we use one-bin sorting (SDCM < 3). This means the 3000K warm white in the lobby matches the 3000K in the penthouse. Nothing looks worse than a hallway where one strip is "pinkish white" and the next is "greenish white."

How Do You Adapt Spaces from "Business" to "Party"?

Modern hotels are multi-use. The rooftop lounge serves breakfast at 7 AM and cocktails at 10 PM. Static white lighting cannot support both moods. You need dynamic control without turning the place into a tacky disco.

Implement Digital RGB+IC strips (Addressable Lighting) combined with smart controllers. This technology allows you to segment the lighting, creating subtle "flowing" effects or slow color transitions that can shift the energy of a room from a bright, productive workspace to a moody, energetic lounge automatically.

Intelligent Atmosphere Management

Lighting automation is the frontier of hospitality. It is not just about "On/Off" anymore; it is about "Scene Setting."

RGB+IC (Independent Control):

Standard color-changing strips (RGB) change the whole roll to one color.

- The Upgrade: Our RGB+IC COB strips contain an Integrated Circuit chip. This allows you to control specific segments (pixels) of the strip individually.

- The Effect: You can program a "Magic Color" chasing effect. Imagine a subtle wave of amber light slowly moving down the bar counter. It directs guest attention and creates movement.

Customization for Signage:

Hotels often need custom neon signage ("The Rooftop," "Bar Open").

- Making these with standard digital strips is hard because the cut points are too far apart.

- Our specialized 12V RGB+IC COB strips feature a cutting unit of just 12.5mm. This extreme precision allows sign makers to cut the strip exactly to the shape of the letter, ensuring the dynamic light effect flows perfectly to the tip of the font without dark spots.

Durability in Dynamic Environments:

We integrate UCS2904 or WS2811 protocols which are widely compatible with major control systems used in hotels (like DMX or Dali via decoders). This ensures your fancy lights actually talk to the hotel’s central control panel reliably.

| Feature | Standard RGB | RGB+IC (Addressable) |

|---|---|---|

| Mood | Static Color Wash | Dynamic / Flowing Motion |

| Control | Global (Whole Room) | Pixel Level (Granular) |

| Best For | Ambient Cove Fill | Bar Fronts, Signage, Features |

| Cut Length | Often 50mm-100mm | High Precision (12.5mm) |

Conclusion

Hospitality lighting is an investment in guest experience. Cheap, dotted, or failing lights signal "neglect" to your customers. By specifying High-Density COB for seamless luxury, IP68 Solid Silicone for worry-free outdoor areas, and 24V High-CRI systems for efficient, beautiful interiors, you protect your property’s image and your bottom line. Do not let your lighting be the reason a guest chooses the hotel across the street next time.

-

Explore this link to understand how COB technology enhances lighting quality and uniformity, crucial for luxury settings. ↩

-

Learn why a high Color Rendering Index is essential for creating appealing dining experiences and enhancing guest satisfaction. ↩

-

Exploring the benefits of the Solid Extrusion Solution can reveal why it’s a superior choice for long-lasting waterproofing. ↩

-

Explore how 2.7mm COB strips can revolutionize your lighting design with their sleek profile and efficiency. ↩

-

Learn about Flip-Chip technology and its advantages in enhancing thermal transfer and efficiency in LED lighting. ↩

-

Explore the advantages of 24V COB strips for efficient lighting solutions and reduced voltage drop. ↩

-

Learn how Double-Sided FPC enhances electrical performance and reduces resistance in lighting systems. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting…

IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…