How Can You Winterize Your LED Strip Installations to Prevent Failure During the Big Freeze?

You have installed thousands of dollars worth of lighting this summer, but as temperatures plummet, you are worried. One cracked casing or frozen connector can cause a system-wide failure, leading to angry clients and expensive emergency service calls in the snow.

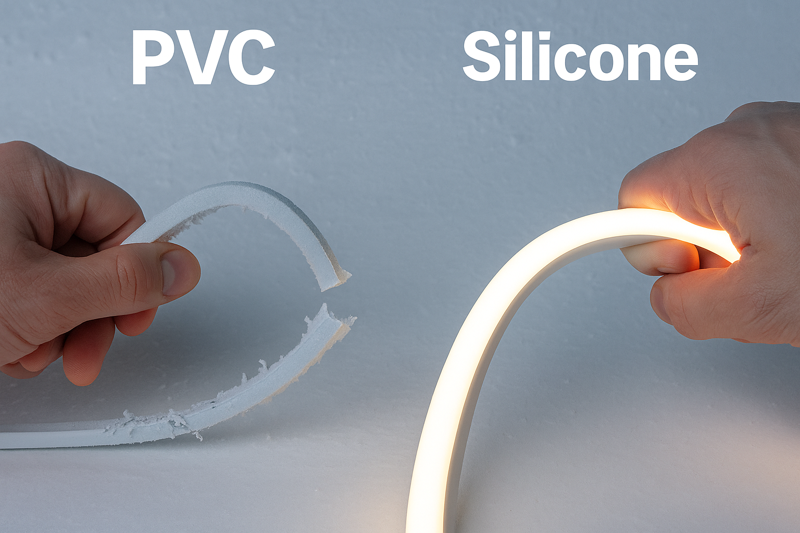

To winterize outdoor LED strips, you must inspect all seals for UV damage, upgrade PVC casings to freeze-proof IP68 Silicone, and seal every connection point with dielectric grease and adhesive-lined heat shrink to prevent expanding ice from popping the circuits open.

As a manufacturer supplying clients in Canada and the Northern US, I know that cold is not the enemy of the LED chip itself—LEDs actually run more efficiently in the cold. The enemy is the material housing them. Plastic contraction and ice expansion are the two forces that destroy outdoor lighting. By taking proactive steps now to "harden" your installations using the industrial-grade materials I produce (like solid silicone extrusion), you can turn a potential warranty nightmare into a reliable, year-round asset for your clients. Here is your professional checklist.

Why Must You Replace PVC Casings with Silicone Before the First Snow?

If your installations use standard LED strips with a PVC (Polyvinyl Chloride) coating, you are sitting on a ticking time bomb. PVC becomes brittle at freezing temperatures.

You need to switch to IP68 Solid Silicone Extrusion strips. Unlike PVC, which hardens and cracks when the temperature drops below 32°F (0°C), food-grade silicone remains soft and flexible down to -40°F, ensuring the waterproof seal never breaks even during shifting ice storms.

This is the most common reason for what I call "The February Failure." In the summer, PVC is fine. But after a season of UV exposure, it weakens. When the first deep freeze hits, the material shrinks. If the strip is mounted to a rigid surface (like a wooden fence or aluminum channel), the shrinking PVC snaps because it lacks elasticity. Once it cracks, melted snow enters, freezes again inside the strip, and destroys the circuit.

In my factory, we use Dual-Color Silicone Extrusion (like in our HC-Neon Series). This material does not cure or harden in the cold. It moves with the temperature changes. If you have clients with old PVC strips, offer them a "Winter Upgrade" now before the snow buries the evidence.

The Physics of Thermal Contraction

To act as a true consultant to your clients, you need to explain the science of why materials fail.

1. The Coefficient of Thermal Expansion (CTE)1

Every material expands when hot and shrinks when cold. The copper PCB inside the strip, the aluminum mounting channel, and the plastic cover all shrink at different rates.

- The Mismatch: If the casing shrinks faster than the copper board inside, it puts tension on the solder joints. Eventually, a resistor pops off.

- The Silicone Solution: Our IP68 Silicone is molded directly over the PCB (Solid Extrusion). There is no air gap. The silicone acts like a shock absorber, holding the components in place even as dimensions shift slightly.

2. UV Degradation Accelerates Winter Failure2

Winter sun is harsh. Reflection off the snow doubles the UV radiation.

- Yellowing: Cheap epoxy coatings turn yellow and rigid.

- The Fix: Our silicone is UV-stabilized. It stays clear. This is crucial because a yellowed strip absorbs more heat from the sun, causing rapid temperature swings (hot day, freezing night) that cycle-stress the electronics.

3. Adhesive Failure

3M tape is useless in winter. The cold hardens the glue, and the strip falls off the wall.

- The Fix: Never verify an installation is "winter-ready" if it relies only on tape. You must use mechanical clips or screw-mounted aluminum channels. Mechanical fasteners don’t care about the temperature.

| Material | Freezing Point Behavior | Winter Risk Level | Recommendation |

|---|---|---|---|

| Epoxy (IP65) | Hardens excessively, cracks immediately | CRITICAL | Remove immediately; indoor use only. |

| PVC Tube (IP67) | Becomes brittle; prone to impact shattering | HIGH | Risky for areas with hail or falling ice. |

| Silicone (IP68) | Retains flexibility and elasticity | LOW | The Industry Standard for winter climates. |

How Do You Stop "Ice Expansion" from Destroying Your Connectors?

The strip might be waterproof, but the connection point is usually not. Water is one of the distinct substances that expands when it freezes (by about 9%).

You must waterproof connections using a "Double-Seal" method: fill the connector body with dielectric grease before closing, and seal the entire exterior with adhesive-lined (marine grade) heat shrink tubing. This eliminates air pockets where water could pool and freeze.

A drop of water inside a connector is harmless in July. In January, that drop freezes and expands with enough force to push the metal pins apart or crack the plastic housing. This breaks the electrical continuity.

For my wholesale clients, I always recommend xConnect or Ray Wu style waterproof pigtails, but even those aren’t perfect. The "Double-Seal" is your insurance:

- Dielectric Grease: It displaces water. If water can’t get in, it can’t freeze.

- Adhesive Heat Shrink: Standard heat shrink is just a sleeve. Adhesive-lined heat shrink melts a layer of glue inside. When it cools, it bonds to the wire jacket, creating a hermetic seal that is impossible for water to penetrate.

Power Supply Cold Starts

The final piece of the puzzle is the engine: the Power Supply Unit (PSU)3.

1. The "Cold Start" Issue

Most electronics hate heat, but power supplies can struggle in extreme cold too. Electrolytic capacitors (the liquid-filled batteries inside the PSU) can freeze or lose capacitance at -20°F.

- The Symptom: You turn the lights on, and they flicker or strobe for 5 minutes before stabilizing. This is the PSU trying to "warm up."

- The Solution: Use purely electronic (solid state) waterproof drivers like the Mean Well XLG series4 or our factory-grade Rainproof Metal PSUs. Avoid cheap plastic "brick" adapters outdoors; they are not insulated enough.

2. Snow Burial Depth

Heat melts snow.

- The Problem: If you mount a PSU on the ground, the heat it generates will melt the snow around it. When you turn it off, that water freezes into a block of ice encasing the PSU.

- The Fix: Always mount power supplies at least 2 feet above the expected snow line, preferably under the soffit or in a NEMA-rated enclosure box5.

3. Voltage Drop in Cold

There is a myth that you need more voltage in winter. Actually, copper becomes a better conductor in the cold (resistance drops).

- The Warning: However, batteries (if you use solar) lose 50% of their capacity. If you are wired to mains power (120V to 24V), you are fine. But ensure your voltage regulator is adjustable. I recommend checking the voltage output at the end of the line now. If it’s barely 22V on a 24V system in summer, it might fluctuate in winter. Bump up the PSU output to 24.5V to be safe.

| Component | Winter Threat | The preventative Fix |

|---|---|---|

| Connector | Ice expansion disconnects pins | Dielectric Grease + Adhesive Heat Shrink6 |

| Power Supply | Capacitor freeze / Ice encasement | Mount above snow line; upgrade to Metal Case. |

| End Caps | Sealant fails, allowing moisture in | Reseal with clear Silicone RTV glue now. |

| Controller | WiFi signal drops in heavy snow | Move closer to access point or hardwire data. |

Conclusion

Winterizing is about managing materials. By trading brittle PVC for IP68 Silicone and mechanically sealing every connection against ice expansion, you ensure your installations survive the freeze, protecting both your reputation and your bottom line.

-

Understanding CTE is crucial for predicting material behavior under temperature changes, ensuring better design and durability. ↩

-

Exploring this topic reveals how UV exposure can compromise material integrity, helping you choose better solutions for harsh environments. ↩

-

Understanding the PSU is crucial for troubleshooting and optimizing your electronics, especially in extreme conditions. ↩

-

Explore the advantages of the Mean Well XLG series for reliable performance in harsh environments. ↩

-

Learn about NEMA-rated enclosures to protect your power supplies from environmental hazards. ↩

-

Discover how these materials enhance the durability and reliability of your electrical connections in cold weather. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…