How Do You Choose a Truly Weatherproof LED Strip for Outdoor Projects?

You installed a beautiful linear lighting system on a building’s facade. For six months, it looked incredible. Then, after one harsh season of sun and rain, sections start to fail. The material is yellowing and cracking, and water has clearly gotten inside, leaving you with a costly and embarrassing failure to fix for your client.

To choose a truly weatherproof LED strip, you must look beyond a simple "waterproof" label. Select the correct IP rating (IP65, IP67, or IP68) for the specific level of water exposure, and critically, ensure the waterproofing material is high-quality, UV-stable silicone, not cheaper epoxy or PU resin that will yellow and fail.

As a manufacturer who has seen a lot of product failures, I can tell you that the outdoor environment is the ultimate test of quality. The most common mistake I see professionals make is assuming any strip with a high IP rating is suitable for any outdoor job. The reality is that the method and material used to achieve that rating are what separate a product that lasts one year from one that lasts ten. For a detail-oriented buyer like Tom, understanding these nuances is the key to avoiding project callbacks, protecting his reputation, and delivering the robust, long-lasting solutions his high-end clients expect. Let’s explore what really makes an LED strip survive and thrive outdoors.

What Do IP Ratings Really Mean for Outdoor LED Strips?

You’re looking at a spec sheet, and you see codes like IP65, IP67, and IP68. They all say "waterproof," but they are for different products at different prices. If you pick the wrong one, you either pay for protection you don’t need or, worse, specify a product that is guaranteed to fail in its environment.

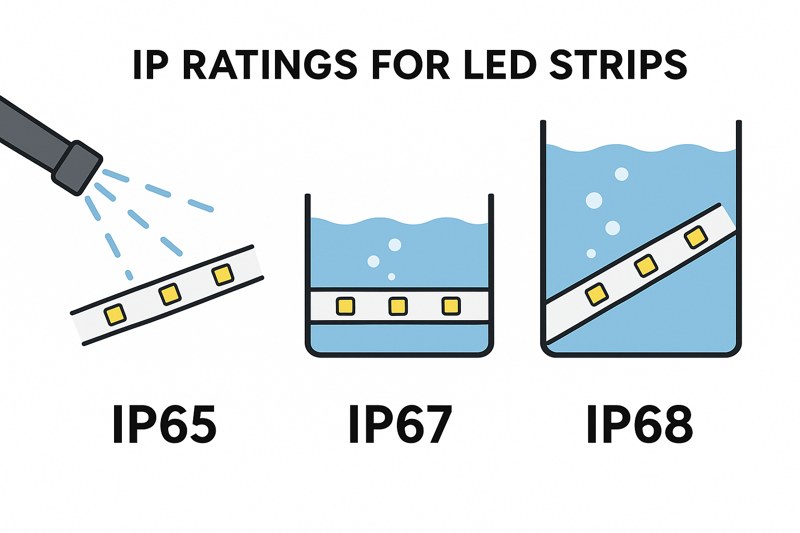

An IP (Ingress Protection) rating is a universal standard that defines how well a product is sealed against solids (like dust) and liquids (like water). For outdoor lighting, IP65 is splash-proof, IP67 can be temporarily submerged, and IP68 is for continuous underwater use. Choosing the correct one is the first step to ensuring reliability.

This two-digit code is the language of durability. It takes the guesswork out of specifying products for tough environments. The first digit refers to protection against solid objects, and the second digit refers to protection against water. For professional outdoor LED lighting, you should only consider products where the first digit is a ‘6’. This means the strip is completely dust-tight, preventing any dirt, dust, or sand from getting inside and damaging the electronics. The second digit is where you need to pay close attention, as it must be carefully matched to the project’s specific location and exposure to the elements. Over-specifying can waste budget, but under-specifying is a recipe for disaster.

A Deeper Dive into IP Ratings and Applications

Understanding this simple code is a fundamental skill for any lighting professional. It allows you to specify with precision and justify your product choices to clients.

-

Breaking Down the IP Code:

Let’s look at the numbers.- First Digit (Solids): For our purposes, we are only concerned with 6.

[IP6X](https://keystonecompliance.com/ip5x-ip6x-dust/)[^1]means the product is fully protected against dust ingress. This is vital for outdoor installations where wind can carry fine particles that can cause short circuits over time. - Second Digit (Liquids): This is the critical variable.

IPX5: Protection against water jets. The product can withstand being sprayed with water from any direction.[IPX7](https://hzo.com/blog/what-does-waterproof-actually-mean-seriously)[^2]: Protection against temporary immersion. The product can be fully submerged in water up to 1 meter deep for a limited time (typically 30 minutes).IPX8: Protection against continuous immersion. The product is sealed for long-term use underwater, at depths specified by the manufacturer (e.g., up to 3 meters).

- First Digit (Solids): For our purposes, we are only concerned with 6.

-

Matching the Rating to the Real World:

The key is to analyze the installation environment honestly. Where will the strip actually live? This is how I advise my clients to choose.

| Application Location | Potential Water Exposure | Required IP Rating | Rationale |

|---|---|---|---|

| Under a Roof Soffit or Covered Porch | Wind-driven rain, splashes, high humidity | IP651 | The strip is shielded from direct downpours but needs protection from angled spray and moisture. IP67 is overkill. |

| Landscape Lighting (Paths, Gardens) | Sprinklers, heavy rain, puddles | IP67 | The strip may sit in temporary puddles after a storm or get directly hit by irrigation systems. It needs to survive brief submersion. |

| In-ground Uplighting (Driveways) | Heavy rain, standing water, pressure washing | IP67 or IP68 | Must withstand temporary flooding and high-pressure cleaning. IP682 is safer if drainage is poor. |

| Inside a Fountain, Pond, or Pool (Step Lighting) | Continuous submersion in treated water | IP68 | The product is permanently underwater. It must have a robust, fully sealed construction to prevent any water ingress over years of use. |

Why is the Waterproofing Material More Important Than the IP Rating?

You specified two different IP67 strips for two similar projects. A year later, one is still perfect, but the other has turned a sickly yellow color, become stiff and brittle, and has water inside. You checked the spec sheet—both were IP67. What went wrong?

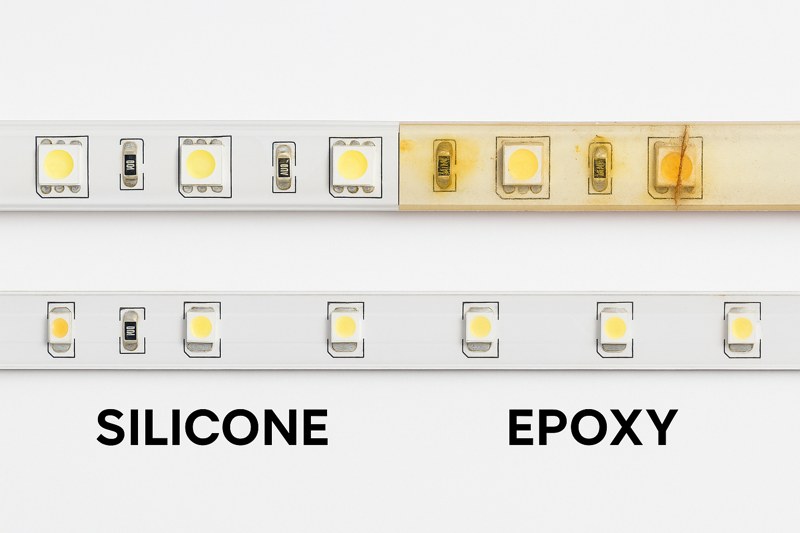

The waterproofing material is the true indicator of long-term quality. Premium strips use silicone extrusion, which is naturally UV-resistant, flexible, and chemically stable. Cheaper strips use a clear PU glue or epoxy coating which degrades in sunlight, turning yellow, cracking, and causing the IP rating to fail.

This is the insider knowledge that separates experienced professionals from amateurs. An IP rating is a measure of a product’s sealing capability when it is new. It says nothing about how that product will perform after a year of being bombarded by UV radiation, heat, and cold. The choice of jacketing material is what determines the long-term viability of the IP rating. As a manufacturer, we can produce a cheap IP67 strip using epoxy resin that will pass the test in the lab, but I would never sell it to a professional like Tom for a serious outdoor project. It is my responsibility to provide a solution that protects his reputation as much as it protects the LEDs.

A Deeper Dive into Material Science

The chemistry of the protective layer is everything. Let’s compare the two main methods used to waterproof an LED strip.

-

The Inferior Method: PU/Epoxy Coating3

This is the cheapest and most common method. A standard non-waterproof LED strip is simply placed in a mold, and a polyurethane (PU) "glue" or epoxy resin is poured over the top surface. It’s fast and inexpensive.- The Failures: Epoxy and PU have a fundamental weakness: they have terrible UV stability4. Sunlight, especially in places like the southern US, breaks down the polymer chains. This causes it to rapidly turn yellow, which ruins the color temperature of the light. The material also becomes hard and brittle. As it expands and contracts with daily temperature changes, microscopic cracks form, allowing moisture to seep in. The IP rating5 is effectively destroyed within a year or two.

-

The Professional Method: Silicone Extrusion6

This is a true manufacturing process. The LED strip is fed through a machine that wraps it in a jacket of high-grade silicone, which is then heat-cured.- The Advantages: Silicone is a superior material in every way for outdoor applications. It is inherently resistant to UV radiation, so it will not yellow or become brittle. It remains flexible across a huge temperature range (-40°C to over 100°C), so it won’t crack during thermal cycling. It also has better chemical resistance. The extrusion process creates a seamless, bonded jacket around the entire strip, providing a much more robust and permanent seal than a simple coating. This is the only method that ensures the product will still meet its IP rating after five years in the field.

| Feature | Epoxy/PU Resin Coating | Full Silicone Extrusion/Jacket |

|---|---|---|

| UV Resistance | Poor. Turns yellow within 1-2 years, altering CCT. | Excellent. Remains optically clear and stable for many years. |

| Flexibility & Durability | Becomes hard and brittle, leading to cracks. | Excellent. Stays permanently flexible, preventing seal breakage. |

| Manufacturing Process | Simple pouring and curing. Low cost. | Industrial extrusion process. Higher cost. |

| Long-Term Seal | Unreliable. Prone to developing micro-cracks. | Highly reliable. Creates a seamless, durable, and permanent seal. |

| Professional Verdict | Unsuitable for permanent, high-quality outdoor projects. | The mandatory choice for professionals who value reliability and reputation. |

How Do You Create a Fully Waterproof Outdoor Lighting System?

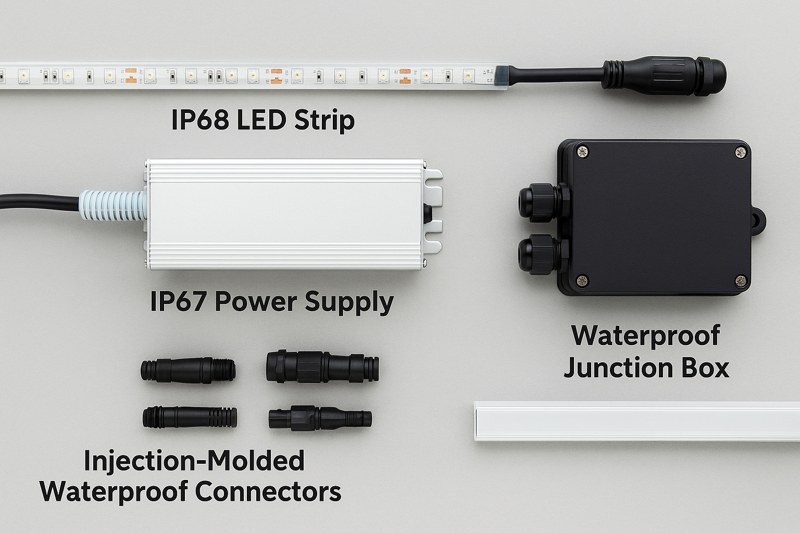

You’ve selected a top-tier, IP68 silicone-extruded LED strip. But a lighting system is more than just the strip. If your connectors fail or your power supply is exposed, the entire project is compromised. How do you ensure every single component is as tough as the strip itself?

A truly waterproof system requires every component to be IP67-rated or higher. This includes using factory-soldered, injection-molded waterproof connectors, IP67-rated power supplies, and sealing all connections within waterproof junction boxes. The system is only as strong as its weakest link.

This is where a "one-station solution" becomes invaluable. Sourcing individual parts from different suppliers is a huge risk. You might get a great strip, but if the connectors you buy separately aren’t properly rated or designed to work with it, you are creating a point of failure. I always tell my clients that we need to think about the entire chain of components, from the power outlet to the last LED. Every connection is a potential entry point for water. By planning a complete, end-to-end waterproof system, you move from installing a product to engineering a permanent solution.

A Deeper Dive into System Components

Let’s build a truly robust outdoor system from the ground up, ensuring every connection point is secure.

-

Connections: The #1 Point of Failure

This is where most DIY and inexperienced installations go wrong. Cutting a waterproof strip and soldering wires in the field is very difficult to re-seal properly.- Field-Installed Connectors: Avoid the clamp-style "solderless" connectors for outdoor use. They are not reliable and provide, at best, a water-resistant seal that will fail.

- Heat Shrink & Silicone7: While better, using heat shrink tubing filled with silicone sealant requires skill and is still less reliable than a factory-made connection.

- Injection-Molded Connectors8: This is the professional standard. We take the cut ends of the strip at the factory, solder the cables on, and then use a high-pressure machine to inject molten plastic around the joint, creating a single, perfectly sealed, IP67/68-rated connector. Always order your strips in the custom lengths you need with the connectors pre-installed at the factory.

-

Power Supplies: The Heart of the System

The power supply (or driver) must also be rated for the environment. Sticking a standard, non-rated power supply in a "water-resistant" box is not good enough.- IP67 Power Supplies9: These are fully sealed, metal-cased units designed to withstand direct exposure to rain. They are the only choice for outdoor installations where the driver cannot be located indoors. Ensure it has waterproof cable glands for all input and output connections. They are built to be tough and manage heat effectively even when fully sealed.

| Component | Standard (Incorrect) Approach | Professional (Correct) IP67+ Solution |

|---|---|---|

| LED Strip | Any strip labeled "waterproof." | Silicone-extruded strip10 with the correct IP rating (65/67/68) for the job. |

| Connections | Cut/solder in the field, use clamp connectors, or basic heat shrink. | Factory-installed, injection-molded waterproof connectors. |

| Power Supply | Standard indoor power supply placed in a junction box. | A fully-rated IP67 waterproof power supply. |

| Wiring | All connections exposed or in non-rated boxes. | All wire-to-wire connections made inside an IP67-rated junction box. |

| Result | A system with multiple, predictable points of failure. | An end-to-end, fully sealed system engineered for long-term reliability. |

Conclusion

For successful outdoor lighting, first choose the right IP rating for the location. Second, and most importantly, insist on a silicone-extruded strip to guarantee long-term UV stability. Finally, complete the project by using a system of fully waterproof connectors and power supplies.

-

Learn why IP65 is essential for protecting outdoor lighting from moisture and ensuring longevity. ↩

-

Discover the benefits of IP68 for underwater lighting, ensuring it remains functional and safe in submerged conditions. ↩

-

Understanding the drawbacks of PU/Epoxy Coating can help you make informed decisions about waterproofing methods. ↩

-

Learn about UV stability and its critical role in the longevity of waterproofing materials. ↩

-

Discover the significance of IP ratings in ensuring the reliability and safety of LED lighting solutions. ↩

-

Explore the benefits of Silicone Extrusion to see why it’s the go-to choice for durable waterproofing solutions. ↩

-

Discover the effectiveness of heat shrink and silicone in protecting connections from moisture and environmental damage. ↩

-

Learn about the advantages of injection-molded connectors for creating durable and waterproof connections. ↩

-

Explore this link to understand how IP67 power supplies ensure reliability and safety in outdoor systems. ↩

-

Find out why silicone-extruded strips are essential for ensuring long-lasting performance in outdoor lighting systems. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…