How Do You Choose Outdoor LED Strips That Actually Survive the Winter?

You installed beautiful outdoor LED lighting for a client in the fall. After the first big snowstorm, they call you, angry. Half the lights are flickering, and some sections are completely dead. Now you have an unhappy client and a costly repair job in freezing weather.

To truly winter-proof an installation, you must use LED strips with an IP67 or IP68 rating, which are fully waterproof. Also, ensure the strip has a wide operating temperature range and is made with durable materials like silicone that won’t crack in the cold.

As a manufacturer providing LED strips for clients in North America and Northern Europe, I know that "weather-resistant" is not enough. Winter is the ultimate test. Water ingress, freezing temperatures, and UV exposure can destroy a low-quality product in a single season. For a business owner like Tom, selling a genuinely winter-proof system builds a reputation for reliability. It’s about choosing the right specifications from the start to avoid those dreaded winter service calls. Let’s break down exactly what to look for, from the materials we use in the factory to the certifications that prove our quality.

What Does the "IP Rating" Really Mean for Winter?

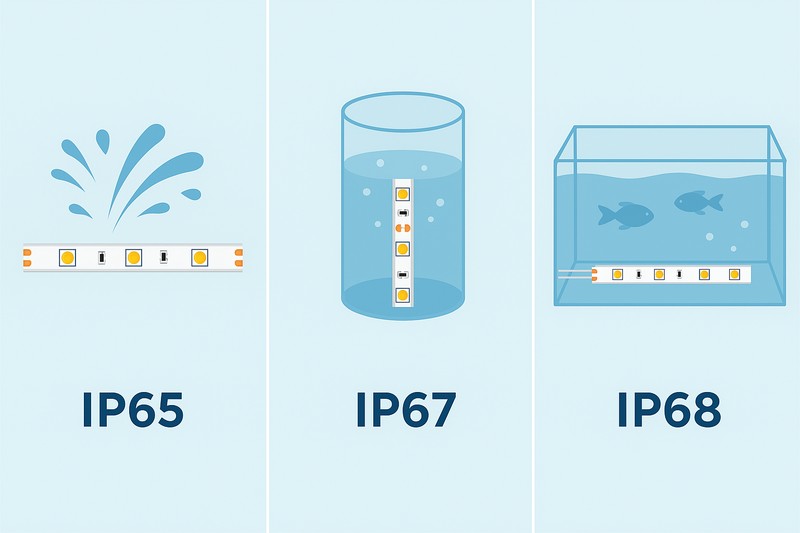

You see different IP ratings like IP65, IP67, and IP68. They all sound "waterproof," but you’re not sure which one you can trust when it’s buried in snow and ice.

The IP (Ingress Protection) rating is the single most important factor. IP65 is only water-resistant and will fail in winter. IP67 is fully waterproof against temporary immersion, and IP68 is for continuous submersion, making them the only reliable choices for harsh winter conditions.

From a factory perspective, the difference between these ratings isn’t just a number; it’s a completely different manufacturing process and level of quality control. An IP65 strip is typically coated with a thin layer of sprayed-on silicone or a basic epoxy resin. The standardized test for IP65 involves spraying it with water jets from any direction, but with no significant pressure and for a limited time. It’s designed to handle rain and splashes, not submersion. When snow piles up on a roofline, melts during a sunny afternoon, and then refreezes at night, it creates pools of standing water and ice dams. This scenario will easily defeat an IP65 coating, as water seeps into micro-cracks or imperfectly sealed ends and destroys the circuitry.

In contrast, IP67 and IP68 strips are fully encased. We use a process called co-extrusion, where the flexible circuit board is fed through a machine and a solid, seamless tube of high-grade silicone is formed around it. The IP67 test is demanding: the product must be fully submerged in 1 meter of water for 30 minutes with no leakage. This gives you and your client peace of mind that the product can easily handle being trapped under an ice dam for days. The end caps are also critical. A cheap IP67 strip might just have glued-on caps, which is a major weak point. We use injection-molded caps that are filled with silicone adhesive and chemically fused to the main body, creating a single, solid, truly waterproof unit. For your clients, this level of manufacturing detail is the true difference between a light that lasts one season and one that lasts for years.

IP Ratings for Outdoor Winter Use

| IP Rating | Level of Protection | Recommended Winter Use Case | My Professional Advice |

|---|---|---|---|

| IP65 | Water-Resistant. Protects from water jets. | Not Recommended. Suitable only for very sheltered locations like a covered porch soffit. | I strongly advise against using IP65 where it can be directly exposed to snow and ice. It will fail. |

| IP671 | Waterproof. Protects from temporary immersion (up to 1m). | Excellent. Perfect for rooflines, decks, railings, and landscape lighting. The professional standard. | This is the go-to choice for 95% of reliable outdoor winter installations. |

| IP682 | Waterproof. Protects from continuous submersion (>1m). | Best. Necessary for in-ground applications, pools, or areas with frequent standing water. | Use this when you need the ultimate level of protection. It’s a sign of a truly premium installation. |

How Does Extreme Cold Affect the LED Strip Materials?

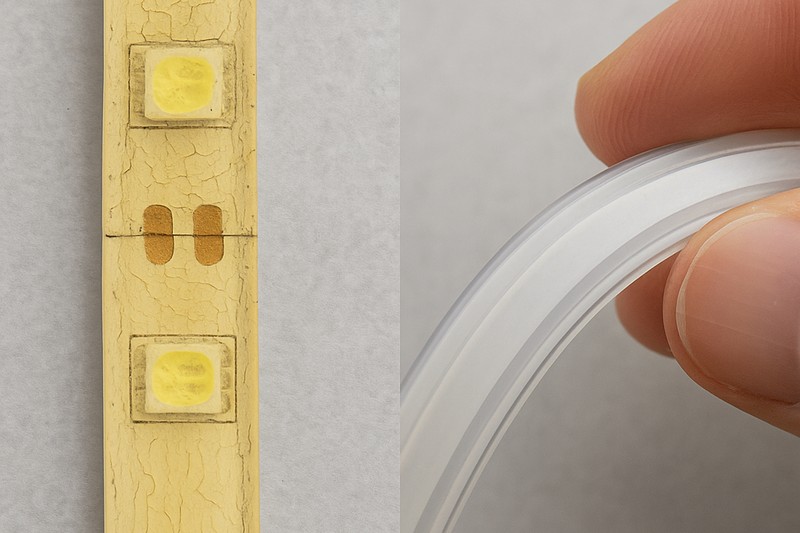

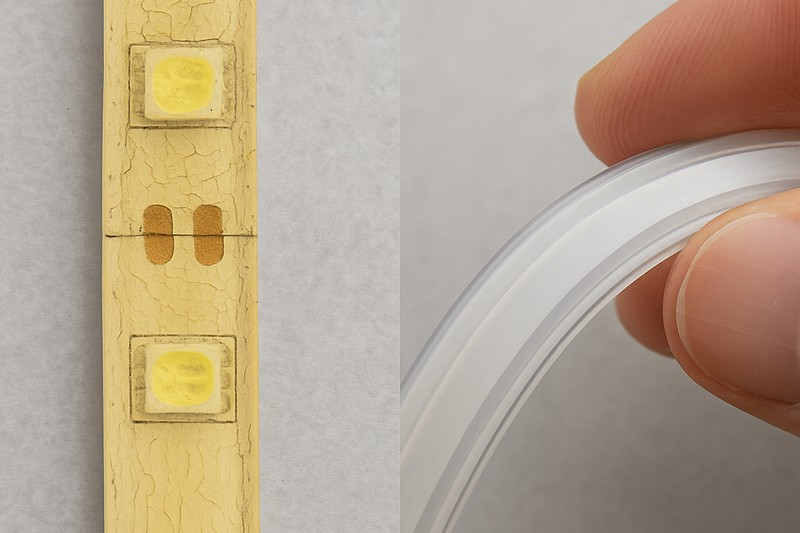

Beyond water, you have another enemy in winter: the cold itself. Freezing temperatures can make plastics brittle and cause materials to contract and crack, breaking the waterproof seal.

The encasement material is critical. Low-quality plastics like PVC or epoxy will become brittle and crack in freezing temperatures. High-grade silicone, however, remains flexible even in extreme cold, maintaining its waterproof seal and protecting the circuitry.

This is a key detail that separates a professional-grade product from a cheap one. When I consult with a buyer like Tom, I always highlight the materials science behind our products. Epoxy coatings and cheap Polyurethane (PU) glues have a very poor thermal coefficient; they expand and contract at a different rate than the PCB and mounting surface. In the cold, they become extremely rigid. The natural thermal expansion of a building’s roofline can cause them to develop micro-cracks. These cracks are death sentences for the strip. Once moisture gets in and freezes, the ice expands and rips the crack wider, guaranteeing failure.

Furthermore, these cheaper materials suffer from severe UV degradation. Even the winter sun will cause them to yellow and become hazy within a single year, which drastically reduces the light output and ruins the aesthetic. High-grade silicone is a superior polymer because it has an excellent operating temperature range, often from -40°C to over 80°C, and it remains flexible throughout. Our silicone includes special UV-inhibiting additives to prevent yellowing for years. Another hidden factor is the Printed Circuit Board (PCB) inside. Cheaper strips use a thin, single-layer PCB. In severe cold, this can become brittle. We insist on using a thicker, more robust flexible PCB with 2-ounce or even 4-ounce copper. This thicker copper provides better heat dissipation in the summer and, crucially, greater structural integrity during the freeze-thaw cycles of winter, preventing the copper traces themselves from cracking under thermal stress.

Winter-Proof Material Checklist

| Component | Bad Material (Will Fail) | Good Material (Will Survive) | Why It Matters |

|---|---|---|---|

| Main Casing | Epoxy, PVC, PU Glue | High-Grade Silicone with UV inhibitors3 | Silicone stays flexible in the cold; others crack and yellow. |

| End Caps | Simple plastic caps, hot glue seal | Injection-molded, silicone-fused caps | A weak end cap is the easiest entry point for moisture. |

| Circuit Board | Thin, single-layer PCB (1oz copper) | Thick, 2-ounce or 4-ounce copper PCB4 | A robust PCB is less prone to cracking from thermal stress. |

What Certifications Actually Matter for Outdoor Winter Use?

You found a supplier with great prices for IP67 strips. But how do you know their claims are real? A fake certificate could mean a failed building inspection or a dangerous liability for your client.

For North American markets, look for UL or ETL listings. These certifications are non-negotiable for safety. They prove a third-party lab has tested the product for electrical shock and fire hazards, which are critical in wet, winter conditions.

As a factory owner, I understand that certifications are a major concern for experienced buyers. It’s easy for a supplier to claim their product is "UL-compliant," but this is a meaningless marketing term. What matters is a "UL Listed" or "ETL Listed" mark, which means the product itself, from the strip to the power supply, has been submitted to and passed rigorous testing by an independent Nationally Recognized Testing Laboratory (NRTL). These tests are not just about waterproofing. They simulate fault conditions, like power surges, and test the flammability of the materials to ensure they won’t start or spread a fire. In the wet and unpredictable conditions of winter, using a non-certified power supply or strip is a significant fire and electric shock risk.

A common pain point for importers is falsified certificates. Any professional buyer should take the extra step to verify a supplier’s claims. You can ask for the UL or ETL file number. Then, you can go to the official UL Follow-Up Services website or Intertek’s ETL directory online and search for that number. This will show you exactly which company holds the certification and which specific product models are covered. If the supplier can’t provide a valid file number, consider it a major red flag. For projects that require inspection, the electrical inspector will look for these marks. Failing an inspection because you used a non-certified product is a costly and embarrassing mistake that can destroy a project’s timeline and your reputation. Insisting on genuine certifications is a core part of professional risk management.

Do You Need Special Connectors and Power Supplies for Winter?

You’ve chosen a tough, certified IP67 silicone strip, but it’s useless if the connections and the power supply fail from moisture. How do you protect the entire system?

Yes, the entire system must be waterproof. Use IP67-rated solderless connectors or, for the most reliable connection, create a soldered connection and seal it with adhesive-lined heat shrink tubing. The power supply must also be IP67-rated and UL/ETL listed.

An LED lighting system is only as strong as its weakest link. A common and costly mistake is to pair a high-quality IP67 strip with cheap, non-waterproof "clamp-style" connectors. These offer zero protection. Water will inevitably wick into the connection through capillary action, and when combined with the low-voltage electricity, it creates the perfect conditions for galvanic corrosion. The copper contacts will turn green and black, creating high resistance, causing the lights to flicker, dim, and ultimately fail. The only truly professional methods are robust. The first is to use specially designed IP67-rated connectors, which have rubber gaskets and a screw-down design. The second, and the method I recommend for maximum, permanent reliability, is to solder the wires directly to the strip’s copper pads. Then, you slide a piece of dual-wall, adhesive-lined heat shrink tubing over the joint. This tubing has an inner layer of thermoplastic adhesive. When you heat it, it not only shrinks to form a tight jacket but also melts the inner glue, which flows to create a permanent, 100% waterproof seal.

The same logic applies to the power supply. An IP67-rated driver is essential, but it also needs to be placed correctly—not just left on the ground where it can be buried in snow or sit in a frozen puddle. All 120V/240V connections must be made inside a proper NEMA-rated waterproof electrical junction box to prevent catastrophic failure and ensure safety code compliance.

Does Snow and Ice Buildup Affect the Light’s Performance?

Your client is worried that after a heavy snowfall, the lights on their roof will be completely buried. Will this damage the strip or significantly reduce the brightness?

Snow and ice will reduce the visible light output, but they will not damage a proper IP67 or IP68 strip. The heat generated by the LEDs themselves is usually enough to melt a thin layer of snow or ice directly around the strip, helping it remain visible.

This is a common concern we hear, but it’s one where physics is on our side. A fully sealed IP67 or IP68 strip is completely protected from the moisture. In fact, being buried in snow can be beneficial for the long-term health of the LED chips. Cold is an excellent heat sink, so the snow actively pulls heat away from the LEDs, running them at a cooler junction temperature, which extends their lifespan and maintains their brightness over the years. The primary concern is light output. While a foot of dense snow will block the light entirely, lighter snowfall often creates a beautiful, glowing effect as the light diffuses through the crystals.

More importantly, let’s consider the aesthetics, an area where lighting designers can add huge value. The reflective nature of snow is a powerful tool. You may not need an ultra-high lumen strip because the snow will amplify the light you have, creating a bright, even illumination across the landscape. The color temperature (CCT) is also critical. A warmer CCT (like 2700K or 3000K) against a cold, blue-toned snowy landscape creates a stunningly cozy and inviting atmosphere, like a warm cabin. A cooler CCT (4000K-5000K) can look crisp, modern, and clean, but can also feel stark if not used thoughtfully. Even an energy-efficient LED strip (e.g., 10-15 watts per meter) produces a small but consistent amount of heat. This warmth is usually enough to melt the snow in direct contact with the strip’s surface, allowing the light to shine out consistently.

Conclusion

Don’t compromise on winter installations. Choose LED strips with a minimum IP67 rating, high-grade silicone, and verified UL/ETL certifications. A system is only as durable as its connections and power supply.

-

Explore this link to understand why IP67 is the professional standard for outdoor winter use, ensuring reliability and safety. ↩

-

Discover the importance of IP68 for in-ground and high-water areas, ensuring your installations withstand harsh winter conditions. ↩

-

Discover how High-Grade Silicone with UV inhibitors can enhance durability and flexibility in cold weather applications. ↩

-

Learn why using a thicker copper PCB can significantly improve the reliability and longevity of electronic devices. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…