How Do You Properly Protect Outdoor LED Strips from Rain, Snow, and Sun?

You’ve designed a stunning outdoor lighting project. The client is thrilled. But a nagging fear remains: will it survive the first year of harsh weather? A single failure from rain, snow, or sun can ruin the entire effect and your reputation along with it.

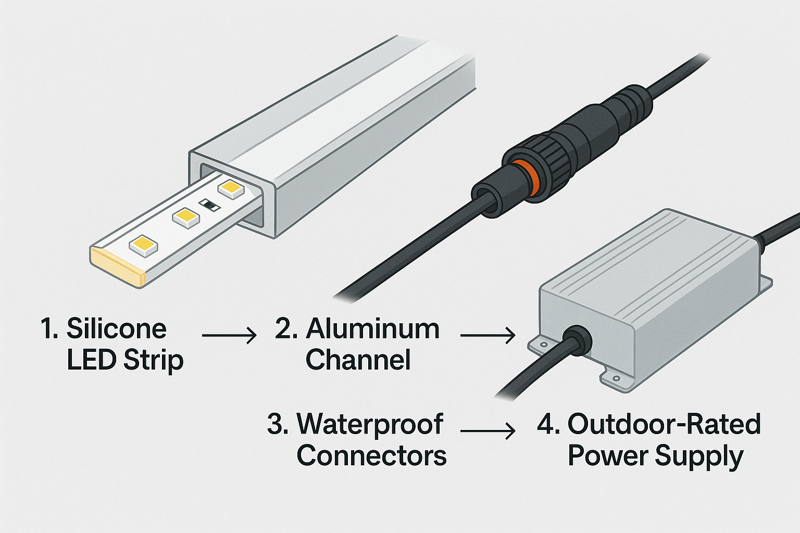

Proper protection is a three-part system: a high IP rating (IP67 or IP68) for water defense, a UV-immune silicone housing to resist sun damage, and professional installation with heat sinks and waterproof connectors to ensure long-term reliability.

As a manufacturer, I can tell you that the single biggest mistake people make is thinking that a "waterproof" or IP rating alone is enough. That rating is only a starting point. Real-world protection means building a system that can defend against all environmental attacks at once. A strip must not only block water but also resist being broken down by sunlight and temperature extremes, all while effectively managing its own heat. This guide breaks down the complete protection strategy, just as we would when engineering a product for a high-stakes commercial project.

Is a High IP Rating Enough to Stop Rain and Snow?

You carefully selected an IP67-rated strip, confident it would be safe from water. But after a season of heavy rain and snow, sections are flickering and failing. You’re left wondering how the "waterproof" light failed.

An IP rating only measures water resistance on day one, under lab conditions. It does not account for material degradation. If the strip’s protective housing cracks or becomes brittle from sun or cold, the IP rating is instantly void, allowing water inside.

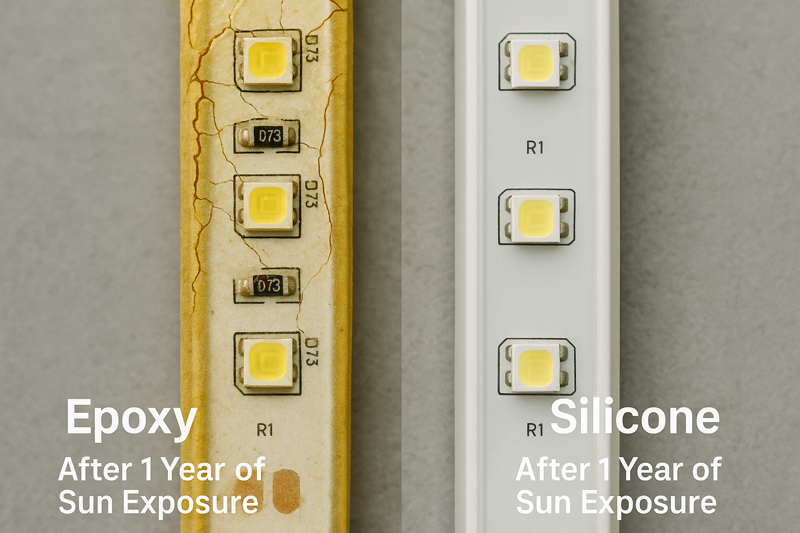

Every day, I talk to clients who have been burned by this. They bought a product that met the spec on paper, but failed in the field. The truth is, a high IP rating on a product made with cheap materials (like epoxy) is a lie. That epoxy will crack after a few months of sun exposure, creating a highway for water to enter. The IP rating only matters if the material housing the electronics can maintain its physical integrity for years. This is why material choice is more important than the initial IP test. A product must stay waterproof.

A Deeper Dive into True Water Protection

Let’s break down what the IP numbers mean and why they are only a piece of the puzzle.

-

Decoding IP Ratings: What IP671 and IP68 Really Mean

The IP (Ingress Protection) code is a standard that tells you the level of protection against solids and liquids.

- First Digit (Solids): For outdoor strips, you should only accept a ‘6’. This signifies the enclosure is "dust-tight," offering complete protection against any solid particle contact.

- Second Digit (Liquids): This is where it gets more nuanced.

- IPX5: Protects against low-pressure water jets from any direction. This is often sold as "weatherproof" but is not sufficient for ground-level or exposed installations. It is not submersible.

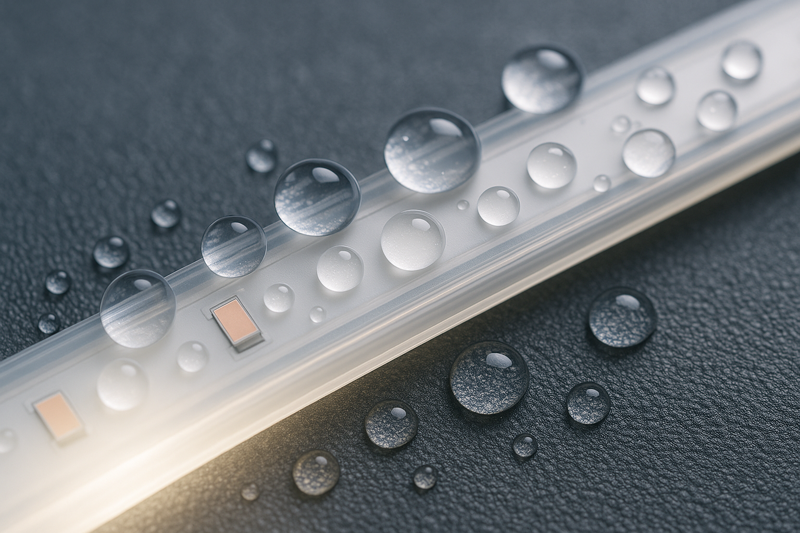

- IPX7: Protects against temporary immersion in water up to 1 meter deep for 30 minutes. This is a strong standard for most outdoor applications.

- IPX8: Protects against continuous immersion in water under conditions specified by the manufacturer. This is critical. An IP68 rating2 is not universal; you must ask the manufacturer, "To what depth and for how long did you test?" We test our IP68 strips to rigorous standards because we know they are used in demanding environments.

-

Why Material Integrity3 is the Real Key

The physical housing is the gatekeeper of the IP rating. If the gate breaks, the rating is meaningless.

- Epoxy’s False Promise: An IP67 epoxy strip passes the test when new. But after one season of sun and temperature changes, it becomes a brittle, cracked shell. Rain and melting snow seep into these cracks, trapping moisture and corroding the circuit board.

- Silicone’s Lasting Seal4: A high-quality silicone housing is inherently immune to UV and remains flexible in extreme cold. It does not crack or become brittle. Therefore, an IP67 silicone strip from day one is still an IP67 silicone strip on day 3,000. It’s the only material that can reliably maintain its waterproof seal for the life of the product.

| IP Rating | Protection Against Solids | Protection Against Liquids | Professional Verdict |

|---|---|---|---|

| IP65 | Dust-Tight | Low-pressure water jets. | Only for sheltered locations (e.g., covered porch). |

| IP67 | Dust-Tight | Temporary immersion (1 meter, 30 mins). | Excellent standard for most outdoor use. |

| IP68 | Dust-Tight | Continuous immersion (depth defined by manufacturer). | Required for pools, ponds, and very wet areas. |

How Does the Sun Secretly Destroy Your Outdoor Lighting?

Your installation survived the winter storms, but after a hot, sunny summer, the lights look terrible. The once-clear coating is now yellow and cloudy, and the light output is noticeably dimmer and off-color.

Sunlight, specifically its ultraviolet (UV) radiation, is a silent killer. It breaks down the polymer bonds in inferior plastics like epoxy and PVC, causing them to yellow, crack, and become brittle. Only inherently UV-immune materials like silicone can withstand long-term sun exposure.

From a material science perspective, this is not a surprise; it’s a chemical certainty. When a low-cost manufacturer chooses epoxy or standard PVC, they are knowingly building a product that will self-destruct under the sun. At our factory, we refuse to use these materials for outdoor products. The UV damage is not just cosmetic. The yellowing can absorb up to 50% of the light output, and the cracks it creates are what ultimately lead to water damage and total failure. For a professional like Tom who needs an installation to look good for years, choosing a UV-stable material is non-negotiable.

A Deeper Dive into UV and Thermal Protection

Let’s explore how the sun attacks a strip in two ways: with UV radiation5 and with pure heat.

-

The Invisible Attack: UV Degradation

UV radiation is high-energy light that physically breaks apart the molecular chains that make up plastics.

- Epoxy and PVC: These materials have carbon-based molecular backbones that are highly susceptible to being broken by UV energy. The result is photodegradation. You see this as a change from clear to yellow or brown, a loss of flexibility, and eventually, surface cracking and disintegration. Manufacturers might add UV inhibitors, but these are sacrificial—they absorb the UV and degrade instead of the plastic, and they eventually run out, leaving the material vulnerable.

- Silicone: Silicone6 has a completely different chemical structure with a silicon-oxygen backbone. The bonds are much stronger and are not broken by the energy of solar UV. This means silicone is naturally immune to UV degradation. It doesn’t need inhibitors. It will not yellow, crack, or become brittle from sun exposure. Its protection is permanent.

-

The Overheating Threat: Thermal Management

The sun also beats down on the strip, adding a significant heat load to the heat already generated by the LEDs themselves.

- Heat is the Enemy: Excess heat is the #1 cause of reduced LED lifespan7 (lumen depreciation). It can also cause undesirable color shifts and, in extreme cases, damage the PCB or solder joints.

- The Aluminum Channel Solution8: This is where the installation method becomes a key part of sun protection. Mounting the strip in an aluminum channel is critical. The aluminum acts as a heat sink, pulling heat away from the sensitive LED chips and dissipating it into the air. This keeps the LEDs running cool, even on a hot, sunny day, preserving their lifespan and light quality. Mounting a high-power strip directly to a surface like wood or stone, which are insulators, traps heat and guarantees premature aging.

What is the "Complete System" for All-Weather Protection?

You’ve chosen a superior silicone IP67 strip and aluminum channels. Are you fully protected? Or are there still weak links that could cause a failure in the field?

The "Complete System" addresses every potential failure point. It combines a high-quality silicone strip and aluminum channel with two other critical components: a stable, outdoor-rated power supply and 100% waterproof connections. The entire chain must be weatherproof.

Understanding the IP67 rating is crucial for selecting the right waterproof products for outdoor use. ↩ Learn how an IP68 rating ensures reliable performance in extreme conditions, essential for outdoor lighting. ↩ Discover the importance of material integrity in maintaining waterproof ratings over time. ↩ Explore why silicone offers superior durability and flexibility for waterproof applications compared to epoxy. ↩ Understanding UV radiation’s impact on materials can help you choose the right products for durability. ↩ Explore the unique properties of silicone that make it a superior choice for UV protection. ↩ Learn about the key factors that influence LED lifespan to ensure optimal performance and longevity. ↩ Discover how using an aluminum channel can enhance LED performance and extend their lifespan. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…