How Long Do Outdoor LED Strip Lights Actually Last?

You promise your client a state-of-the-art lighting system that will last for years. But deep down, you’re worried. You’ve seen other jobs with lights that fail after one season, and you can’t afford the callback or the damage to your reputation.

A high-quality, professionally installed outdoor LED strip should last for 30,000 to 50,000 hours, which is typically 5 to 10 years of regular use. However, this is only achievable when using strips with superior components, silicone housings, and proper heat dissipation. Cheaper strips often fail completely in just 1-2 years.

As a manufacturer, I deal with lifespan numbers every day. But the numbers we use for engineering are very different from the numbers used in marketing. The truth is, the 50,000-hour figure you see everywhere is not a guarantee; it’s a best-case scenario. The actual, real-world lifespan of your installation depends entirely on the quality of the product you choose and how you install it. Understanding what makes a strip last is the key to protecting your work and your profits. Let’s break down the factors that really matter.

Why is the "50,000-Hour" Rating Often Misleading?

You purchase a product with a "50,000-hour lifespan" proudly printed on the box. You install it, but two years later, it’s flickering or dead. You feel like you were lied to, and you don’t know who to trust.

The 50,000-hour rating (L70) only measures how long it takes for the LED chip to dim to 70% of its original brightness under perfect laboratory conditions. It does not measure or predict catastrophic failure from cracked housings, water damage, or solder joint breaks, which are the real reasons most strips fail prematurely.

This is the biggest misunderstanding in the lighting industry, and it causes endless frustration for contractors. The L70 rating is a useful metric for comparing the quality of one LED chip to another, but it has very little to do with the lifespan of the entire outdoor strip light system. The LED chip itself is an incredibly robust piece of technology; it’s almost never the first thing to fail. The weak link is always the support structure around it: the protective coating, the circuit board, and the solder joints. A cheap strip fails not because the LEDs have dimmed, but because the entire product has fallen apart.

A Deeper Dive into Lifespan Metrics

Let’s look at what that 50,000-hour number really means and why it doesn’t apply to the real world of outdoor installations.

-

What is L70 B501?

The full technical term is often L70 B50.

- L70: This means the point in time when the light output has degraded to 70% of its initial brightness. Our eyes can’t perceive a significant drop in brightness until it reaches about this point.

- B50: This means that in a large batch of tested LEDs, 50% of them will have met or exceeded the L70 lifespan. This means 50% will fail to meet it! Sometimes you see B10, which means only 10% fail to meet the L70 rating, which is a higher quality standard.

-

The "Perfect Conditions" Lie

This L70 rating is determined by testing the bare LED chip in a highly controlled laboratory environment.

- Constant Temperature: The test is run at a fixed, ideal ambient temperature (e.g., 25°C). It does not account for the brutal thermal cycling2 of a hot day followed by a cold night.

- Perfect Power: The LEDs are powered by a perfectly regulated, laboratory-grade power supply with no voltage spikes or fluctuations.

- No Environmental Stress: The bare chip is not exposed to UV radiation, humidity, water, vibration, or physical impact.

In the real world, the product is exposed to all of these stresses at once. The sun’s UV radiation attacks the housing. Rain and humidity try to get inside. The temperature swings from freezing to blistering, stressing the solder joints. The power supply might not be perfect. This is why a cheap epoxy-coated strip with a "50,000-hour" LED inside it will still fail in 18 months. The LED chip is fine, but the system built around it has disintegrated. As a professional, you must ignore the marketing headline and instead evaluate the quality of the materials and construction of the entire product.

How Does the Protective Housing Determine Real-World Lifespan?

You did your research and selected an IP67-rated strip, so you know it’s protected from water. But after a year, it has yellowed and become brittle, and now water is getting in anyway. What went wrong with the "waterproof" rating?

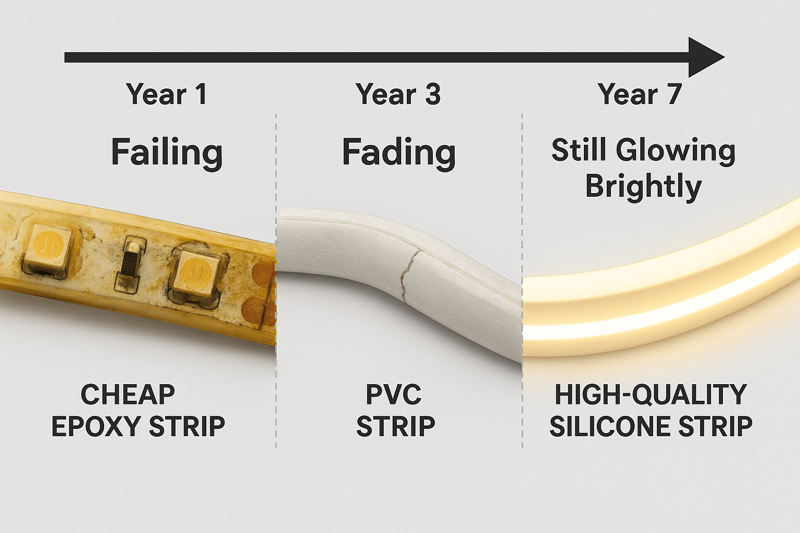

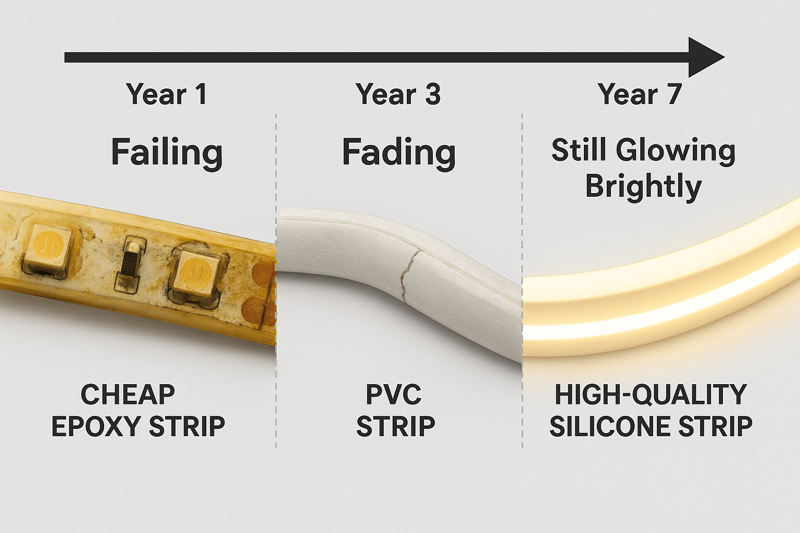

The IP rating is only valid on day one. The lifespan of the waterproofing depends entirely on the housing material. An epoxy or PVC housing will degrade in sunlight and cold, cracking within 1-4 years and allowing water in. Only a high-quality silicone housing will maintain its integrity and its IP rating for 5-10+ years.

At my factory, this is the most important distinction we make for outdoor products. The choice of housing material is the choice of lifespan. A cheap material is a ticking time bomb that guarantees the failure of the entire strip, no matter how good the LEDs are inside. Thinking about this in terms of a failure timeline makes it very clear. A product is only as strong as its weakest link, and for outdoor strips, the housing is almost always the weakest link.

A Deeper Dive into the Lifespan of Each Material

Let’s project the realistic lifespan you can expect based on the an outdoor strip’s housing material.

-

Epoxy Resin Coating3 (Lifespan: 1-2 Years)

This is the lowest-cost option and has the shortest life.

- Year 1: Noticeable yellowing will occur within the first 6-12 months, especially in sunny climates. This yellowing not only looks bad but it can reduce light output by 20-30%. The material will have lost its flexibility and become hard.

- Year 2: The daily cycle of thermal expansion and contraction4 will cause the now-brittle epoxy to form micro-cracks. Water will penetrate these cracks, bypassing the IP rating. Corrosion will begin on the PCB, leading to flickering sections and complete failure. This is its end of life.

-

PVC Jacket5 (Lifespan: 2-4 Years)

This is a step up in physical toughness, but has its own critical environmental flaws.

- Years 1-2: The PVC will perform reasonably well, though some fading or "chalking" from UV exposure may begin to appear. Its light transmission remains fairly stable.

- The First Cold Winter: The real test is cold. Below freezing, PVC becomes rigid. If it’s a particularly cold winter (below -15°C), or if the strip is disturbed or bent while cold, it can crack. A single crack destroys its waterproof integrity and leads to failure.

- Years 3-4: If it survives the cold, continued UV exposure will make it less flexible and more discolored. Its lifespan is limited by either UV degradation or cold-weather cracking. It’s an unreliable choice for a four-season climate.

-

Silicone Extrusion6 (Lifespan: 5-10+ Years)

This is the professional standard for a reason.

- Years 1-5: The silicone housing will show virtually no signs of degradation. It remains perfectly clear and fully flexible. It is immune to UV radiation, so it will not yellow or cloud over. It remains pliable in extreme cold, so it will not crack. The IP rating is completely maintained.

- Years 5-10+: During this period, the electronic components are the only limiting factor. The LEDs will slowly dim according to their L70 rating. Eventually, after many years, a resistor or solder joint might fail from fatigue. But the housing itself will not fail. The strip lives out its full, intended electronic lifespan because it is properly protected.

Does Installation Method Affect the Lifespan of LED Strips?

You’ve done everything right. You bought a premium, silicone-extruded IP67 LED strip. But after a few years, you notice it’s visibly dimmer than when you installed it. What could be causing this premature aging?

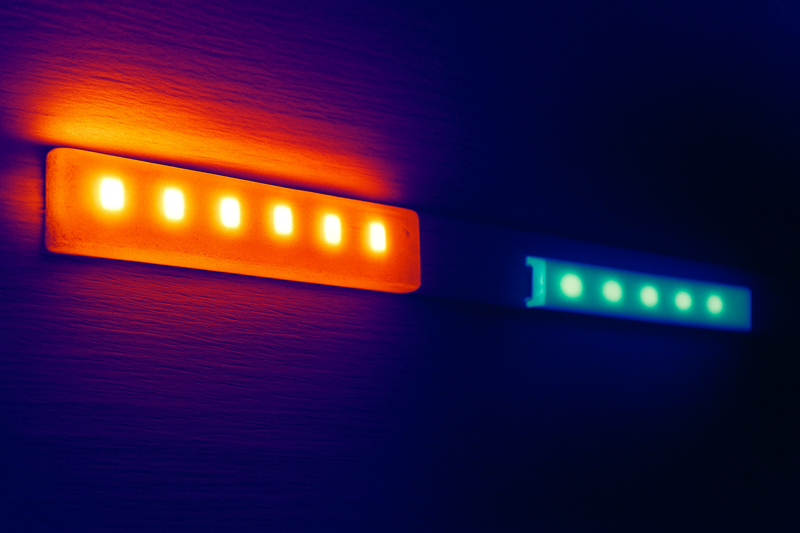

Yes, installation is a critical factor. Heat is the primary enemy of an LED’s long-term brightness. Installing an LED strip without a metal heat sink, like an aluminum channel, can trap heat and cut the effective L70 lifespan in half or even more.

This is a step that many people unfortunately see as optional. They see the aluminum channel as just a cosmetic accessory for creating a clean line of light. But from an engineering perspective, its primary role for high-power strips is thermal management. The "50,000-hour" rating is based on the LED operating at a specific, cool temperature. Every degree you go over that temperature drastically accelerates the aging process of the LED chip. Failing to use a heat sink is like choosing to shorten the life of your investment.

A Deeper Dive into How Installation Determines Lifespan

Let’s explore the practical impact of heat and other installation factors on a strip’s longevity.

-

The Science of Heat and Lumen Depreciation

The lifespan of an LED is inversely proportional to its operating temperature.

- The Rule of Thumb: For every 10°C increase in the LED’s junction temperature7, its expected lifespan is cut by roughly 50%.

- Real-World Example: Let’s say you have a 50,000-hour (L70) strip.

- Installed correctly in an aluminum channel, it runs at an optimal 45°C. It will likely achieve its full 50,000-hour life.

- Installed directly onto a wooden surface (which is a thermal insulator), it might run at 65°C. That’s a 20°C increase. Its expected lifespan isn’t 50,000 hours anymore. It’s closer to 12,500 hours (50,000 -> 25,000 -> 12,500). You have quartered the effective life of the product simply by trapping heat.

-

It’s Not Just About Dimming

Extreme heat also causes other failures that can kill a strip long before it dims.

- Color Shift8: Heat damages the phosphors on white LEDs, causing their color temperature to shift, usually becoming yellower. Your cool white can turn into a dingy warm white.

- Component Failure: The other electronic components on the circuit board—resistors, capacitors, driver ICs—also have their lifespans shortened by heat. Excessive heat can cause solder joints to fatigue and crack much faster, leading to a dead section.

-

Other Installation Factors

- Power Supply: Using a cheap, unregulated power supply that delivers "dirty" or fluctuating voltage will stress and destroy LEDs. Always use a high-quality, Class 2 power supply9 rated for the correct voltage.

- Connections: The points where you connect strips to wires are potential failure points. All outdoor connections must be made 100% waterproof using methods like solder-sealed connectors10, RTV silicone-filled caps, and marine-grade heat shrink tubing. A single bad connection can let water into the whole system.

Conclusion

The actual lifespan of an outdoor LED strip is not a single number. It is a direct result of professional choices: specifying quality silicone, installing with aluminum channels, and using proper power and connections. Do it right, and you get a decade of reliable light.

-

Understanding L70 B50 is crucial for evaluating LED quality and lifespan, ensuring you make informed purchasing decisions. ↩

-

Exploring the impact of thermal cycling on LEDs can help you choose more durable lighting solutions for outdoor installations. ↩

-

Explore this link to understand the limitations and lifespan of epoxy resin coatings, crucial for making informed material choices. ↩

-

Understanding thermal expansion and contraction is key to selecting materials that withstand environmental changes. ↩

-

Learn about the performance of PVC jackets in cold weather to ensure reliability in your outdoor projects. ↩

-

Discover why silicone extrusion is the preferred choice for outdoor lighting, ensuring durability and longevity. ↩

-

Understanding the junction temperature is crucial for maximizing LED lifespan and performance. ↩

-

Explore how heat affects LED color quality and learn to maintain consistent lighting. ↩

-

Discover the significance of using quality power supplies to ensure LED longevity and reliability. ↩

-

Learn about the benefits of waterproof connections to prevent failures in LED systems. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…