IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone rings. It’s the hotel manager screaming that half the outdoor lighting is flickering, and the other half is dead. You specified "waterproof" lights, so what went wrong? In the lighting game, "waterproof" is a marketing term; IP Ratings are the engineering reality.

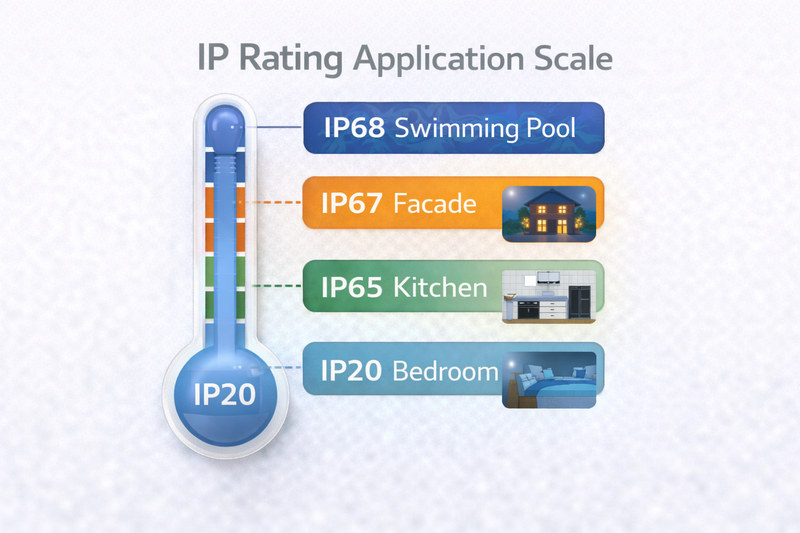

To prevent catastrophic failure, you must match the Ingress Protection (IP) rating to the specific environment. Use IP20 for dry indoor coves to maximize heat dissipation; IP65 (Coated) for damp kitchens and bathrooms; IP67 (Hollow Extrusion) for outdoor rain exposure; and IP68 (Solid Extrusion) for underwater submersion or extreme weather where pressure resistance is required.

As the owner of a factory that exports thousands of meters of LED strips to North America and Japan every month, I see the same expensive mistake repeated constantly. Contractors treat IP65, IP67, and IP68 as interchangeable synonyms for "outdoor." They are not. Using the wrong one doesn’t just mean water gets in—it can mean your LEDs overheat, turn yellow, or crack during installation. Let’s dive into the microscopic details of waterproofing so you can buy with confidence.

Is IP65 "Waterproof" Enough for Outdoor Use?

Many suppliers will tell you, "Yes, this strip has a silicone coating, it is IP65, it is fine for the patio." Do not listen to them. If you install standard IP65 glue-coated strips in direct sunlight and rain, you will be replacing them in six months.

IP65 typically utilizes a "Surface Glue" or "Potting Compound" method on top of the PCB. While it protects against low-pressure water jets and splashes (ideal for kitchens or under-cabinet lighting), it lacks the complete sealing required for long-term outdoor exposure. UV rays often degrade the thin top coating, leading to cracking and eventual water ingress.

The "Potting Compound" Reality

When you look at our catalog, you will see IP65 described as "potting compound waterproofing1" or simply a surface coating.

What is it chemically?

It is usually a thin layer of silicone or epoxy dropped over the top of the LED chips. The back of the PCB (where the adhesive tape is) is often exposed or only thinly treated.

Why it fails outdoors:

- Thermal Expansion: Outdoors, temperatures swing wildy. The copper PCB expands at a different rate than the hardening glue. Over time, this causes delamination. Once the glue lifts, water gets underneath, shorts the resistors, and your strip dies.

- UV Degradation2: If the manufacturer uses cheap epoxy glue instead of high-grade silicone, the sun will turn that clear coating yellow and brittle within months. A yellow coating shifts your 4000K white light to a sickly 2700K yellow mud.

- Physical Protection: IP65 coating is soft. A weed whacker or a stray branch can scrape it off easily.

Where I recommend IP65:

- Bathrooms: Perfect for mirror backlights where steam is the issue.

- Kitchens: Under-cabinet lighting where grease or boiling water splash is a risk.

- Bar Counters: Where drinks might spill.

- Why not just use IP68 inside? Heat. The thin IP65 coating allows heat to escape fairly well. A thick IP68 tube traps heat. If you use heavy waterproofing indoors where it isn’t needed, you are just cooking your chips and shortening their lifespan.

IP67 vs. IP68: What is the Difference Between "Hollow" and "Solid"?

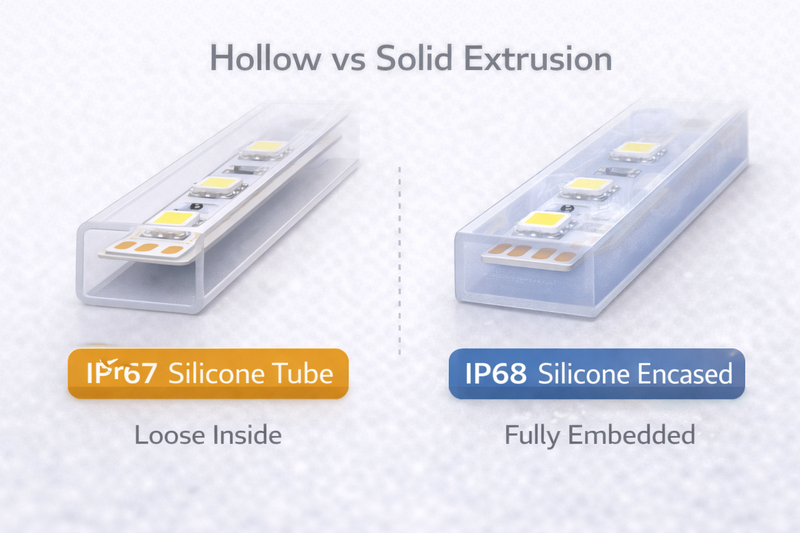

This is the most common point of confusion for my US clients. They confuse "rainproof" with "submersible." If you put an IP67 strip in a fountain, it will fail. Why? Because inside the tube, there is air.

The critical difference lies in the extrusion method. IP67 usually employs "Hollow Extrusion" (a silicone sleeve with air inside), making it lighter and good for rain protection. IP68 uses "Solid Extrusion" (fully filled with silicone), eliminating all air gaps. This solid construction prevents the "capillary effect" that sucks water into hollow tubes during temperature changes.

The Physics of The "Vacuum Effect"

In our factory testing, we distinguish these clearly: IP67 is hollow extrusion, and IP683 is solid extrusion.

The IP67 "Hollow" Risk:

Imagine a silicone sleeve with the LED strip sliding inside. It looks waterproof. It works great against rain.

- The Problem: When the lights are on, the air inside the tube heats up and expands. It pushes out through microscopic gaps in the end caps.

- The Disaster: When you turn the lights off at night, the air cools and contracts. This creates a vacuum4. The tube literally sucks in air (and moisture) from the outside environment to equalize pressure. Over a few weeks of this "breathing" cycle, your tube fills with water.

- Best Use: Building facades, eaves, and signage where water runs off quickly and doesn’t pool.

The IP68 "Solid" Solution:

We inject liquid silicone into the mold so it completely encapsulates every resistor and diode. There is no air.

- No Air = No Vacuum. The strip cannot "breathe" in water because there is no space for it.

- Pressure Resistance: You can put this underwater (up to a certain depth) because the solid mass resists water pressure.

- Engineering Note: Because we are adding a thick layer of material on top, you will lose some brightness. Always compensate by ordering a slightly higher lumen output for IP68 projects.

Why IP20 is Still the King of Commercial Performance?

With all this talk of protection, you might be tempted to just order IP68 for everything "to be safe." This is a rookie mistake. In professional lighting design, less protection is often better.

IP20 (Non-Waterproof) features the bare LED chip exposed to the air. This offers the best possible heat dissipation, the highest lumen output, and the most consistent color temperature. For aluminum profile installations or architectural coves where moisture is not a threat, IP20 is the superior technical choice due to its thermal efficiency and lower cost.

Let It Breathe

In high-end architectural projects, we use IP205 for 90% of the indirect lighting.

The Thermal Advantage:

LEDs don’t emit heat forward (like halogen); they emit heat backward into the PCB.

- An IP20 strip allows convection cooling directly from the chip surface to the air.

- An IP686 strip insulates the chip in a blanket of silicone.

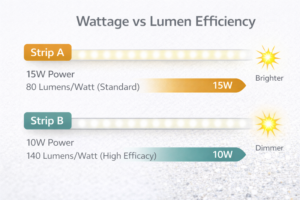

- Result: An IP20 strip running at 15W/meter will last significantly longer and stay brighter than an IP68 strip running at the same power, simply because it runs cooler.

The "Aluminum Channel" Hack:

If you are installing lights into a designated aluminum channel with a plastic diffuser cover (PC cover), you do not need IP65/67 strips.

- The aluminum channel is the protection.

- The cover protects against dust and curious fingers.

- Using an IP65 strip inside a covered aluminum channel effectively "double bags" the light. The heat has nowhere to go. The silicone turns yellow, the PC cover gets brittle, and the light fails.

- My Advice: Inside a channel? Use IP20. Always.

Cost Efficiency:

Waterproofing processes (extrusion machinery, silicone material, labor to seal ends) add 20-30% to the cost of the strip. By using IP20 where appropriate, you free up budget to buy higher quality chips (High CRI) or better power supplies.

Does Bending Destroy Your IP Rating?

I shipped a container of IP68 lights to a landscape project in California. Two weeks later, the installer called saying the strips were cracking. I asked for a photo. They had folded the strip 90 degrees around a sharp concrete corner.

Waterproof strips have structural limitations. The extrusion material makes them thicker and stiffer. Specifications mandate a minimum bending diameter (usually R > 15mm or 60mm). Forcing a waterproof strip into a sharp 90-degree fold physically tears the silicone casing or delaminates the PCB, instantly voiding the IP rating and allowing water ingress.

Structural Integrity vs. Installation Reality

When we manufacture a COB Strip7 or an SMD Strip8 with waterproofing, we change its physical properties.

The "R > 15mm" Rule:

In our technical datasheets, you will see a warning: "bending diameter: R > 15mm" and "Please do not fold it in half."

- The Physics: Imagine a garden hose. If you bend it gently, it flows. If you kink it hard, it collapses. Solid silicone extrusion works the same way.

- If you force a sharp corner, the outer edge of the silicone stretches until it snaps (micro-tears), or the inner edge of the copper PCB buckles and detaches from the silicone.

- Once that seal is broken, capillary action will suck water into the tear, traveling down the strip and destroying the first group of LEDs.

The "Sideways" Bend:

Standard LED strips can only bend up and down (like a rollercoaster loop). They cannot bend left to right (like a snake slithering).

- Warning: If you try to bend a standard IP67/68 strip sideways to go around a curved pool edge, you will rip the casing.

- The Solution: For "snake" bends, you must order specialized S-Shape (Zig-Zag) strips or Run Silicone Neon Flex which is specifically molded for lateral bending.

Installation Protocol for Corners:

Never wrap a waterproof strip around a sharp 90-degree corner continuously.

- Cut the strip at the corner.

- Use a flexible, waterproof jumper connector (or solder wires).

- Seal the connection with liquid silicone and a shrink tube.

This relieves the physical stress on the corner and maintains the seal.

Why Is the "End Cap" the Most Dangerous Part of the System?

You can have the best IP68 strip in the world, but if the installer cuts it to length and does a sloppy job sealing the end, the whole system collapses. A waterproof chain is only as strong as its weakest link—the cut point.

Industrial waterproofing is done by machine injection molding at the factory. When you cut a strip on-site, you destroy that factory seal. You must essentially recreate the IP rating manually using end caps, neutral acid-free silicone glue, and heat-shrink tubing. 95% of field failures occur at these manually protected connection points.

Factory Injection vs. Field DIY

When we sell you a 5-meter roll of IP68 light, the ends are sealed by a machine that injects molten silicone into a mold. It is chemically bonded. It is bulletproof.

The Contractor’s Reality:

You rarely need exactly 5 meters. You cut it at 3.2 meters. Now you have a raw, exposed PCB sitting in the rain.

The Right Way to Seal (The Rhstriplighting Protocol):

- The Glue: Do not use standard construction adhesive. You need Neutral Cure Silicone. Acid cure silicone (which smells like vinegar) will eat through the copper pads of the LED strip over time.

- The Cap: Use the specific silicone end cap provided in the accessory bag. Do not use generic tape.

- The Process: Fill the cap half-full with glue. Push it onto the clean, dry strip end. Wipe off excess. Wait 24 hours.

- The Mistake: Most installers turn the lights on immediately. The heat from the LEDs interferes with the curing process of the glue, creating bubbles. You must let the chemical bond set before powering up.

Connector Advice:

Avoid "clip-on" solderless connectors for outdoor use if possible. They pierce the PCB and invite corrosion. For permanent outdoor longevity, soldering wires and then sealing the entire joint in a glue-filled shrinkage tube is the only method I guarantee for 5 years.

Conclusion

Ingress Protection is not just a label; it operates based on material science.

- Use IP20 for indoor coves to save money and reduce heat.

- Use IP65 (Glue/Potting) for indoor damp areas like bathrooms, but keep it out of the sun.

- Use IP67 (Hollow Extrusion) for vertical outdoor surfaces where rain runs off.

- Use IP68 (Solid Extrusion) for horizontal outdoor surfaces, pools, and anywhere water might pool.

And remember: The IP rating only applies to the continuous strip. The moment you cut it, you are responsible for the waterproofing. Seal those ends like your reputation depends on it—because it does.

-

Explore this link to understand the science behind potting compounds and their effectiveness in waterproofing. ↩

-

Learn about UV degradation and prevention methods to protect your products from sun damage. ↩

-

Exploring IP68 waterproofing benefits can help you make informed decisions for projects requiring high durability and moisture resistance. ↩

-

Understanding the vacuum effect is crucial for grasping how pressure changes can impact materials, especially in engineering. ↩

-

Explore the advantages of IP20 for indirect lighting, including cost efficiency and thermal performance. ↩

-

Learn about the differences between IP68 and IP20, especially regarding heat management and longevity. ↩

-

Explore this link to understand the versatility and applications of COB Strips in various lighting solutions. ↩

-

Learn about SMD Strips and their benefits in LED technology, enhancing your knowledge of modern lighting. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

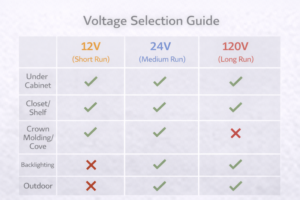

12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…

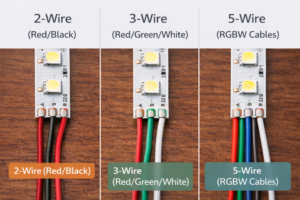

2-Wire vs 3-Wire vs 5-Wire LED Rope Lights Explained: Are You Wiring Your Project for Failure?

You have landed a lucrative commercial lighting contract, the design is approved, and the budget is set. But when the…