Is a Premium Outdoor LED Strip Light Worth the Investment?

That budget-friendly outdoor LED strip looks great on the invoice. But a year later, it’s a yellow, flickering wreck, and your client is furious, costing you much more than you saved.

Yes. Premium LED strips are worth it because they use durable, UV-resistant silicone, 24V systems for consistent brightness, and have verifiable safety certifications. This prevents costly failures, protecting your profits and reputation, unlike budget strips which fail quickly.

As a factory owner, I see the precise corners that are cut to create a "budget" product. The upfront saving is a trap that leads to higher long-term costs in labor, replacement products, and—most importantly—your reputation. Let’s break down exactly what you’re paying for when you choose a premium product.

What’s the Real Difference in ‘Weatherproofing’?

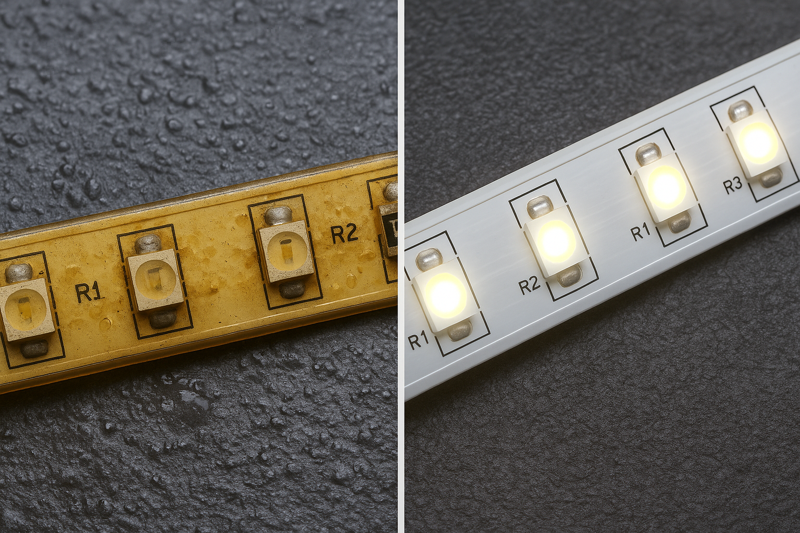

Your budget strip had an IP67 rating on the box. But after just one season of sun and rain, it’s flickering and full of water. The cheap coating has cracked, making the rating worthless.

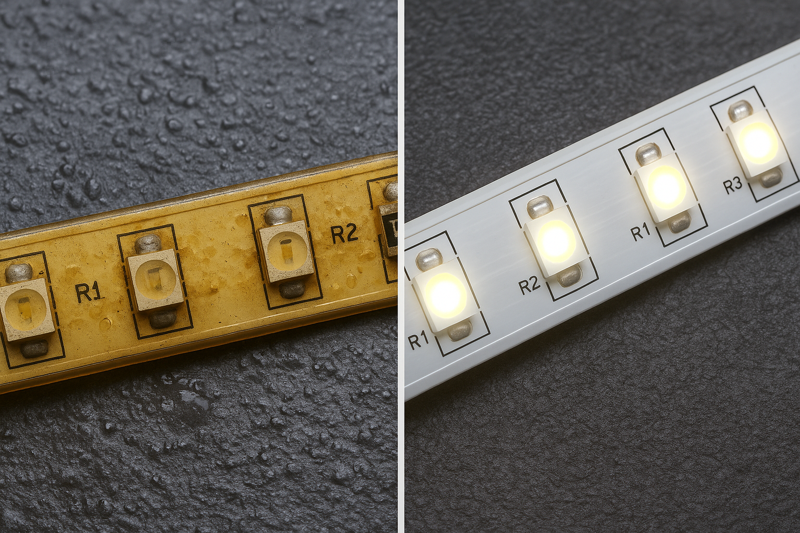

The difference is the material. Premium strips use UV-resistant silicone that stays flexible and won’t crack under sun exposure. Budget strips use cheap PU or epoxy that rapidly yellows, becomes brittle, and cracks open, allowing water to destroy the electronics.

I see this exact failure more than any other. A client sends me a photo of a failed installation, and I can immediately identify the brittle, yellowed plastic coating. An IP rating is only as good as the material that creates the seal. A premium strip is built with materials designed to survive years of sun and temperature swings, not just pass a one-time water test in a lab.

The Battle of Materials

The sun is the ultimate enemy of outdoor plastics. How a strip’s body material handles UV radiation determines its true lifespan.

The Failure of Budget Coatings (PU/Epoxy)

Polyurethane (PU) and epoxy1 are cheap organic plastics that are fundamentally unstable when exposed to UV light. This process, called photodegradation, breaks down their chemical bonds. It causes two major problems. First, it turns the material a sickly yellow-brown, ruining the aesthetic and altering the light color. Second, and more critically, it makes the material hard and brittle. As it expands and contracts with daily temperature changes, it develops micro-cracks that grow, allowing moisture to seep in and kill the LEDs.

The Durability of Premium Silicone2

Silicone is a highly stable, inorganic material. Its internal structure is not susceptible to UV damage. This means it remains optically clear and, most importantly, flexible for years. This enduring flexibility allows it to maintain a perfect waterproof seal as it deals with freezing winters and hot summers. It won’t crack, shrink, or peel away from the circuit board.

| Feature | Budget Strip (PU/Epoxy) | Premium Strip (Silicone) |

|---|---|---|

| Material Type | Organic Plastic | Inorganic Polymer |

| UV Resistance | Poor (Yellows/Cracks) | Excellent (Stays Clear/Flexible) |

| Longevity | 1-2 Year Lifespan | 5+ Year Lifespan |

| IP Rating Integrity | Fails Over Time | Maintained for Years |

Why Do Budget Strips Look Dim and Inconsistent?

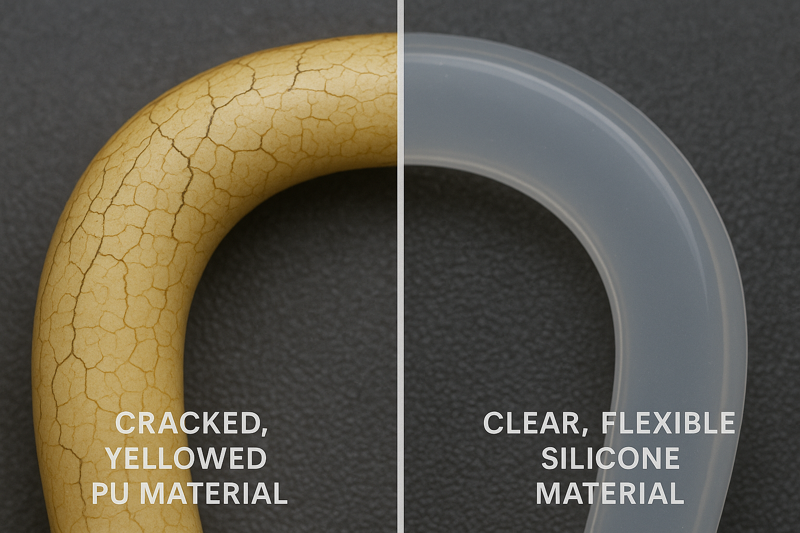

You installed a 40-foot run of lighting along a building facade. The first half is bright white, but the second half is a dim, sad yellow. The entire project looks unprofessional and cheap.

Budget strips typically use a 12V system, which causes severe voltage drop and dimming on long runs. They also use cheap, unsorted LEDs with inconsistent color. Premium strips use a 24V system for even power and tightly binned LEDs for perfect color uniformity.

When a professional lighting designer specifies a product, "consistency" is one of their top requirements. They cannot tolerate a beautiful design being ruined by a product that can’t maintain its brightness or color. This is a fundamental difference in engineering. Budget strips are made for short, simple applications. Premium strips are engineered for long, demanding architectural installations.

The Engineering of Perfect Light

Achieving a flawless line of light over long distances is a matter of physics and quality control.

The Problem of Voltage Drop3

This is a simple law of electricity. As power travels along a conductor, it loses voltage. In a 12V system, this drop is significant enough to starve the LEDs at the far end of the strip, making them appear dimmer and often warmer in color. Budget products only come in 12V because it’s cheaper to produce. A premium 24V system pushes the same power with half the electrical current. This drastically reduces voltage drop, ensuring the last LED on the strip is just as bright and color-correct as the first one.

The Secret to Color Uniformity

The term "white light" covers a huge range. "LED binning4" is a quality control process where manufacturers sort LEDs into batches ("bins") based on their exact color tint. Premium manufacturers buy LEDs from a single, very tight bin to guarantee every LED on the reel is a perfect match. Budget strip makers buy leftover LEDs from many different bins and mix them together, which is why you see ugly shifts from white to pink or green.

| Feature | Budget Strip | Premium Strip |

|---|---|---|

| System Voltage | 12V Only | 24V Standard for Long Runs |

| Brightness | Inconsistent / Fades | Consistent End-to-End |

| LED Quality | Wide Bin / Unsorted | Single Bin / 3-Step MacAdam Ellipse |

| Visual Result | Looks Amateurish and Uneven | Looks Professional and Flawless |

How Do Safety Certifications Impact Your Business?

A supplier offers you a price that seems too good to be true, and it probably is. When you ask for the UL file number to verify their safety claims, they can’t provide it.

Legitimate certifications like UL Listing are crucial business protection. They are independent proof that a product is safe from fire hazards and its IP rating is real. Budget strips often have no certifications or, worse, use fake ones, exposing you to massive liability.

For a professional buyer like Tom, this is not a small detail – it’s a critical risk management issue. Installing an uncertified electrical product can void a client’s property insurance, lead to failed inspections, and make you personally liable in the event of a fire or accident. A premium product’s price includes the significant cost of undergoing this rigorous third-party testing to protect you.

The Business Case for Certified Products

A safety certification isn’t an expense; it’s a form of insurance for your business.

The Risk of Uncertified Products

A budget strip with no UL or ETL mark has not been tested by an independent lab. You have no way of knowing if it will overheat, if its components are flame-retardant, or if its wiring can handle a power surge. It is an unknown liability. Some suppliers will even put a fake UL logo on their products. This is why you must always ask for the file number and verify it yourself in the online UL database. A refusal to provide this number is a major red flag.

The Value of Verified Proof

A UL Listed product1 has been intentionally subjected to abuse in a lab to ensure it fails safely. It’s been tested for electrical shock, fire risk, and for outdoor products, its IP rating has been verified through intense water-ingress testing. It is your guarantee to your client—and your insurance company—that you have installed a product that meets North American safety standards. It’s a mark of professionalism that separates you from low-bid competitors.

| Feature | Budget Strip | Premium Strip |

|---|---|---|

| Certification | None or Fake/Unverifiable | Verifiable UL or ETL Listing |

| Fire/Safety Risk | High / Unknown | Low / Tested |

| Liability | Installer Assumes Full Risk | Risk Minimized by 3rd-Party Proof |

| Client Trust | Low | High |

Conclusion

The choice isn’t budget versus premium. It’s about a cheap, failing product versus a reliable, professional-grade investment that protects your business, your projects, and your valuable reputation.

-

Understanding the impact of UV light on these materials can help you make informed choices for outdoor applications. ↩ ↩

-

Explore the advantages of Premium Silicone to see why it’s the superior choice for durability and UV resistance. ↩

-

Understanding voltage drop is crucial for ensuring consistent LED brightness across long distances. ↩

-

Exploring LED binning will help you appreciate how color uniformity is achieved in high-quality lighting. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…