Is a Premium Outdoor LED Strip Really Worth the Extra Cost?

You see two outdoor LED strips with the same IP rating. One is half the price of the other. Your budget says go for the cheaper one, but your gut warns you of hidden problems that could lead to an angry client and costly repairs down the line.

A premium outdoor LED strip is worth the cost because it uses superior materials and components that ensure long-term reliability. The key differences are UV-stable silicone for waterproofing (not cheap epoxy), high-CRI LEDs with consistent binning for light quality, and thicker copper PCBs for durability.

I’ve been manufacturing LED strips for years, and I’ve dissected countless failed products sent to me by frustrated contractors. In almost every case, the failure of a budget outdoor strip was predictable from the moment it was made. The spec sheet might look the same, but the hidden choices in materials and components are what separate a one-year product from a ten-year solution. For a professional buyer like Tom, understanding these differences is the key to protecting his profits, his timeline, and his hard-won reputation. Let’s pull back the curtain and see exactly where the money goes when you invest in a premium product.

Why Do Budget Strips Fail in the Sun and Rain?

You installed a "waterproof" budget strip, and it looked fine for a few months. Then, after one hot summer, the client calls you. The strip has turned a ugly yellow, it’s stiff and cracked, and there are dark spots where water has clearly gotten inside. What went wrong?

Budget strips fail because they use cheap epoxy or PU resin for waterproofing. This material is not UV stable and is quickly destroyed by sunlight. Premium strips use silicone extrusion, a material that is immune to UV damage and maintains a flexible, perfect seal for years.

This is, without a doubt, the single biggest difference between a professional outdoor product and a cheap imitation. An IP rating is tested on a new product in a lab. It tells you nothing about how that product will perform after 500 hours of direct sun exposure. The choice of encapsulating material is the true test of longevity. I had a client in Florida send me a one-year-old budget strip from a competitor that had literally crumbled in his hands like a dry cracker. He saved 30% on the purchase, but then had to pay to replace the entire installation. This is the exact scenario that a premium product is designed to prevent.

A Deeper Dive into Waterproofing Materials

The material science behind the waterproofing is what determines the real-world lifespan of an outdoor LED strip. It’s a simple choice at the factory that has massive consequences in the field.

-

The Budget Method: Epoxy or PU Resin Coating1

This is the fastest and cheapest way to get a "waterproof" rating. A standard indoor strip is placed in a shallow mold, and a clear polyurethane (PU) glue or epoxy resin is poured over the top. It looks good when it’s new, but the polymer chemistry is fundamentally flawed for outdoor use. The UV radiation from the sun acts like a chemical hammer, breaking the bonds in the resin. This process causes two catastrophic failures. First, it turns the resin a sickly yellow-brown color. This completely changes the color temperature of your light, turning a beautiful 3000K warm white into something that looks dirty and old. Second, the material becomes extremely hard and brittle. As it heats up and cools down every day, it can’t flex with the strip and the mounting surface. This thermal cycling2 causes microscopic cracks to form, which grow larger over time. Water then wicks into these cracks, and the IP rating becomes meaningless. -

The Professional Method: Full Silicone Extrusion3

This is a true industrial process. The bare LED strip is fed through an extrusion machine that wraps the entire product—top, bottom, and sides—in a thick, seamless jacket of high-grade silicone. The product is then cured at high temperatures. Silicone is a completely different class of material. It is inherently immune to UV radiation. It will not yellow, harden, or crack. It also remains flexible over an enormous temperature range, from deep-freeze winters to scorching desert summers (-50°C to 200°C). This permanent flexibility and UV stability mean that the IP67 or IP68 seal4 you get on day one is the same seal you will have in year five and beyond. It is the only professional method for guaranteeing long-term outdoor performance.

| Feature | Budget (Epoxy/PU Coating) | Premium (Silicone Extrusion) |

|---|---|---|

| UV Resistance | Poor. Turns yellow within 1-2 years. | Excellent. Optically clear for 10+ years. |

| Durability | Becomes hard and brittle, leading to cracks and failure. | Excellent. Remains permanently flexible, preventing seal breakage. |

| Longevity of Seal | Unreliable. The IP rating is temporary and will fail. | Reliable. The IP rating is permanent for the life of the product. |

| Professional Verdict | High Risk. A guaranteed future failure point. | Low Risk. The mandatory choice for reliable projects. |

Does ‘Good Enough’ Light Quality Ruin a High-End Project?

The budget strips are installed and waterproofed. They all turn on. But when you stand back, something is wrong. The light on the beautiful gray stonework looks slightly pink in one section and slightly green in another. The vibrant colors of the landscape now look dull and lifeless.

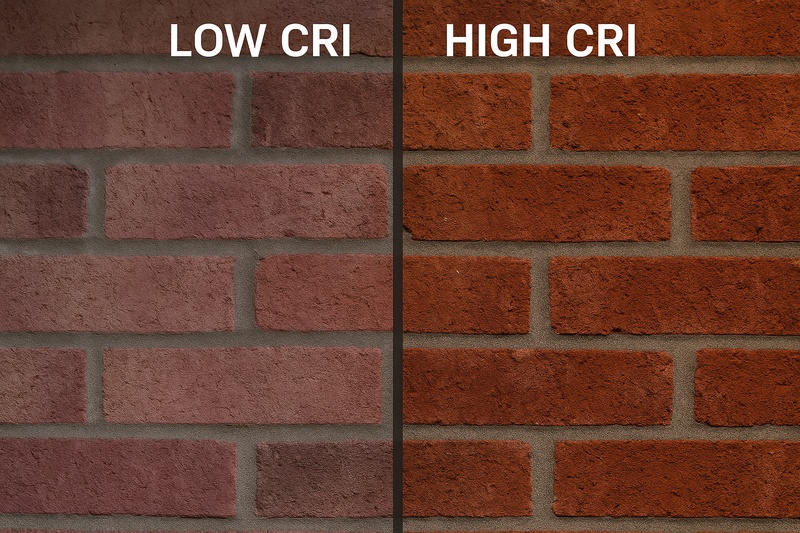

Budget strips use cheap LEDs with poor color rendering and are not sorted consistently (poor binning). Premium strips use high-CRI (90+) LEDs from top-tier suppliers, sorted into tight bins to guarantee perfect color accuracy and consistency along the entire project.

This is the subtle mistake that can cheapen an entire multi-million dollar project. The lighting is the final touch, the element that is supposed to enhance the architecture and materials. If the light itself is of poor quality, it can have the opposite effect. As a manufacturer, I can buy LEDs for a few cents per piece, or for ten times that amount. Both will produce "light." But a professional buyer like Tom understands that his clients are paying for a specific aesthetic effect. Low-quality light makes expensive materials look cheap. It’s like hanging a masterpiece painting and illuminating it with a gas station bathroom light. The quality of the light source is everything.

A Deeper Dive into LED Quality: CRI and Binning

The quality of the tiny LED chips themselves is a major cost driver, and a major factor in the final visual result. This is an area where budget manufacturers make huge compromises.

-

The Truth About LED Binning5

When LEDs are made, they don’t all come out exactly the same. There are slight variations in color and brightness from one chip to the next. In a high-quality factory, every single LED is tested and sorted into containers called "bins" based on its exact characteristics. This is a costly process. Premium LED strips6 are built using LEDs from a single, very tight bin (e.g., following a 3-Step MacAdam ellipse). This ensures that every LED on the strip is visually identical to the one next to it, and every reel of strip you buy is identical to the last one. Budget manufacturers7 buy unsorted LEDs or cheap mixed bins. The result is a "checkerboard" or "striped" effect where you can see visible color differences from section to section. It looks terrible and is the mark of an amateur installation. -

Why a High Color Rendering Index (CRI)8 is Not Optional

CRI measures how accurately a light source shows the true colors of an object. The sun is 100 CRI. A cheap LED might be 70 CRI. A professional LED should be 90 CRI or higher. With 70 CRI light, a rich redwood deck will look a dull, flat brown. The deep greens of a Japanese maple will look washed out. The subtle warm tones in a piece of granite will simply disappear. A 90+ CRI light makes these same colors pop with vibrancy and richness, exactly as they appear in daylight. For any high-end project where natural materials are being lit, high CRI is not a luxury; it is a fundamental requirement to do justice to the architect’s material choices.

| Feature | Budget Strips | Premium Strips |

|---|---|---|

| Color Rendering (CRI) | Typically 70-80 CRI. Makes colors look flat and dull. | 90+ CRI. Renders colors vibrantly and accurately. |

| Color Consistency | Poor binning. Visible color differences ("stripes"). | Tight Binning. Perfect color consistency along the entire length. |

| Long-Term Color Shift | High. The color can shift significantly over its life. | Low. The color remains stable for thousands of hours. |

| Professional Verdict | Compromises the project’s aesthetics. Looks cheap. | Enhances the project. Makes materials look their best. |

What Hidden Flaws in Budget Strips Cause Flickering and Failure?

The job is done. Two months later, the client calls. A three-foot section in the middle of a run is completely dead. Another section is flickering. Now you have to send a crew out to diagnose and replace it, erasing the profit you made on the job.

Budget strips use thin, 1oz copper PCBs (Printed Circuit Boards) and cheap components that cannot handle heat or stress. Premium strips use thick 2oz or 3oz copper PCBs for superior heat dissipation, along with high-quality resistors, ensuring long-term electronic stability.

This is the stuff you cannot see, but it is one of the most common causes of premature failure. The LED strip is an electronic circuit, and its reliability depends on the quality of every component. Heat is the number one enemy of an LED. If you cannot pull heat away from the LED chip effectively, its lifespan will be drastically shortened. The PCB is the primary highway for heat to escape. Budget manufacturers save a few pennies per meter by using the thinnest possible copper layer. This is a fatal flaw for a product that is supposed to last for 50,000 hours. It’s a conscious choice to build a product that will not last, and it’s something we would never do.

A Deeper Dive into Unseen Components

Let’s look at the internal foundation of the strip. The choices made here determine whether the strip will live a long, stable life or die an early death.

-

The Importance of PCB Copper Weight9

The copper layer in a flexible PCB is measured in ounces per square foot. A 1oz PCB is the standard for cheap, low-power indoor strips. Using this on a brighter, outdoor-rated strip is a recipe for failure. The thin copper simply cannot draw heat away from the LEDs fast enough. The LEDs overheat, which causes two problems: first, their brightness degrades much faster (this is called lumen depreciation10), and second, it leads to total failure. A premium strip uses a 2oz, 3oz, or even 4oz copper PCB. This thick layer acts as a massive heatsink, efficiently pulling thermal energy away from the tiny LED chips and dissipating it. This keeps the LEDs running cool, which is why we can confidently offer a 5-year warranty. It directly translates to a longer, more reliable product life. -

Resistors and Solder Joints: The Ticking Time Bombs

Every small section of an LED strip has a surface-mounted resistor to regulate the current. Budget strips use the smallest, cheapest resistors possible. These can easily burn out, which is the most common reason for a single section of a strip to go dark. Furthermore, in an outdoor environment with wide temperature swings, the entire strip is constantly expanding and contracting. Budget manufacturers use cheap solder that can become brittle and fracture under this constant thermal stress, leading to flickering or intermittent connections. A premium strip uses high-quality, correctly-sized resistors and a more ductile solder11 paste that is engineered to withstand years of thermal cycling without failing.

| Feature | Budget Strips | Premium Strips |

|---|---|---|

| PCB Copper Weight | 1oz copper. Poor heat dissipation. | 2oz, 3oz, or 4oz copper. Excellent heat dissipation. |

| LED Lifespan (Lumen Decay) | High. LEDs overheat and dim quickly. | Low. LEDs stay cool, maintaining brightness for years. |

| Component Quality | Cheap resistors, brittle solder. Prone to failure. | High-grade resistors, ductile solder. Designed for reliability. |

| Overall Electronic Reliability | Poor. High chance of dead sections or flickering. | Excellent. Designed for a long, stable, maintenance-free life. |

Conclusion

Choosing a premium strip is not a higher cost; it is a lower risk. You are investing in reliable materials, beautiful light quality, and robust engineering. You are buying peace of mind for yourself and delivering a permanent, professional result for your client.

-

Learn about PU Resin Coating, its benefits, and limitations in waterproofing to make informed choices. ↩

-

Learn about thermal cycling and its impact on material durability, especially in outdoor applications. ↩

-

Discover the advantages of Silicone Extrusion in waterproofing and why it’s preferred for outdoor LED strips. ↩

-

Explore the significance of IP ratings to ensure your waterproofing solutions meet industry standards. ↩

-

Understanding LED Binning helps you choose quality lighting solutions that ensure color consistency and visual appeal. ↩

-

Discover the advantages of premium LED strips for achieving vibrant colors and consistent lighting in your projects. ↩

-

Learn about the pitfalls of budget manufacturers to avoid poor lighting choices that can ruin your design aesthetics. ↩

-

Exploring CRI will help you appreciate how lighting affects color perception, crucial for high-end design projects. ↩

-

Understanding PCB Copper Weight is crucial for ensuring optimal heat dissipation and longevity of LED strips. ↩

-

Explore the causes of lumen depreciation to learn how to maintain LED brightness over time. ↩

-

Learn about ductile solder and its benefits in preventing failures in electronic components. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…