Is Your Deck Lighting Enhancing the Experience or Just Adding Glare?

You invest heavily in composite decking and stone pavers, yet at night, your project looks flat and uninviting. Poor lighting ruins the ambiance of high-end outdoor spaces.

To create a professional finish, avoid cheap 12V kits. Use 24V COB LED strips with IP68 solid extrusion technology. This ensures a seamless, dot-free glow that matches the quality of your build and withstands rain or standing water without failure.

In my experience manufacturing for the US market, I see many contractors treat lighting as an afterthought. They grab what is available at the local depot. Six months later, the lights dim, or water gets in. Your reputation depends on the longevity of your install. Let’s look at the specific technical details you need to source to avoid these callbacks.

Which Waterproof Rating Do You Actually Need?

Water is the number one killer of outdoor LEDs. If you install standard "splash-proof" strips on a deck, you are guaranteeing a failure within the first year.

Do not settle for IP65. For heavy outdoor use and areas with standing water, you require IP68 Solid Extrusion. This completely encases the PCB in silicone, preventing water ingress even if the strip is submerged in a puddle.

The Science of Silicone Extrusion1

When you source lighting for an outdoor deck, the material is just as important as the rating. In the US market, I often see cheap PVC casings. These turn yellow and brittle after one hot summer. This is why we prioritize Silicone Extrusion in our factory. However, the rating system itself is often misunderstood by buyers.

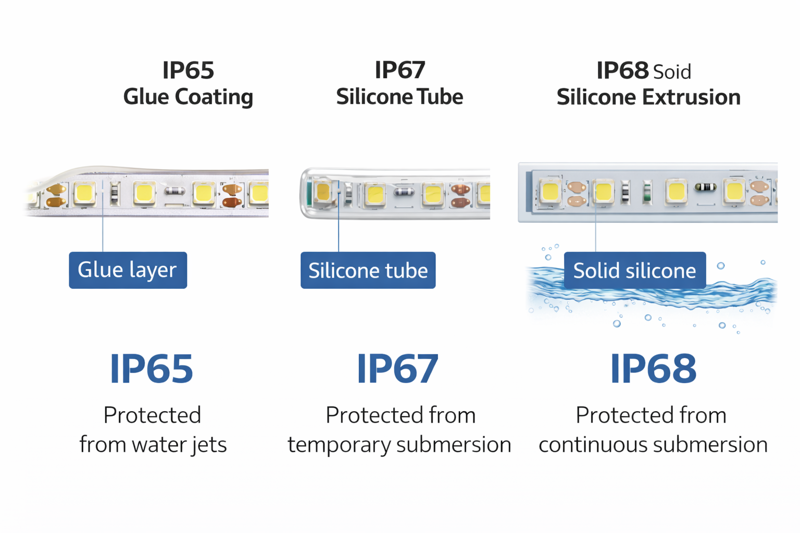

You need to understand the three levels of protection we manufacture to make the right choice for your client:

- IP65 (Potting Compound): This uses a glue dropping technique on the surface. It is fine for damp kitchens, but outdoors, the thermal expansion often cracks the glue.

- IP67 (Hollow Extrusion): This is a silicone sleeve. It is great for under-railings where the light is sheltered. However, because it is hollow, condensation can form inside if the end caps aren’t perfect.

- IP68 (Solid Extrusion / Underwater Engineering): This is the gold standard for decks. We fill the entire extrusion with silicone. There is no air gap. Our catalog defines this specifically for "Underwater lighting engineering."

Many of my OEM clients initially ask for IP65 because it is cheaper. I always tell them: think about the snow melting on a stair tread. That light strip sits in water for days. Only IP68 waterproofing by solid extrusion2 can handle that pressure. If you use a hollow tube (IP67), water eventually gets in. By sourcing IP68, you eliminate water damage claims entirely.

| IP Rating | Construction Method | Best Application | Risk Level |

|---|---|---|---|

| IP65 | Potting compound (glue) | Indoor wet areas | High (Cracks in UV) |

| IP67 | Hollow extrusion | Sheltered handrails | Medium (Condensation) |

| IP68 | Solid extrusion | Open decks, stairs, pools | Zero (Submersible) |

Are You Still Installing "Dots"?

Visible LED beads reflected on glass railings or polished stone floors look cheap. Your clients expect a smooth, high-end "neon" look, not a dotted line.

Switch to High-Density COB strips. These chips are mounted directly to the board, creating a continuous line of light with no dark areas, perfect for under-railings and steps where the fixture acts as a direct visual element.

Why COB is the New Standard

In the past, to hide the "dots" of an SMD (Surface Mounted Device) strip, you had to use deep aluminum channels with thick milky diffusers. This reduced your brightness and looked chunky. Today, COB (Chip on Board)3 technology changes the game.

We manufacture these strips with incredibly high density. For example, our 24V models often pack 320 LEDs or even 480 LEDs per meter. Because the chips are so close together, there is "No sense of LED bead particles" visually. The light is uniform directly from the reel.

Handling and Installation:

While COB is superior visually, it requires care during installation. I see installers treat LED strips like copper wire, bending them around sharp 90-degree corners. This is a mistake.

- Bending: You must respect the bending diameter. Our specs warn: "Bending diameter R > 15mm." If you fold it sharper than that, you snap the internal circuit.

- Direction: These strips bend up and down, but never sideways. Our data sheet states specifically: "Please do not bend it horizontally."

Color Rendering (CRI):

Don’t ignore the quality of light. If your client used expensive Redwood or Ipe wood, a cheap light makes it look grey. We use Ra904 (CRI 90+) as a standard for our COB lines. This brings out the true, rich color of the wood grain and stone textures.

| Feature | Old SMD Tech | Professional COB Tech |

|---|---|---|

| Visual | Visible dots | No dark areas / Uniform |

| Density | 60-120 LEDs/m | 320-480 LEDs/m |

| Need for Diffuser | Mandatory | Optional |

| CRI (Color Quality) | Often Ra80 | Ra90 Standard |

12V vs 24V vs 48V: How Long Can You Run?

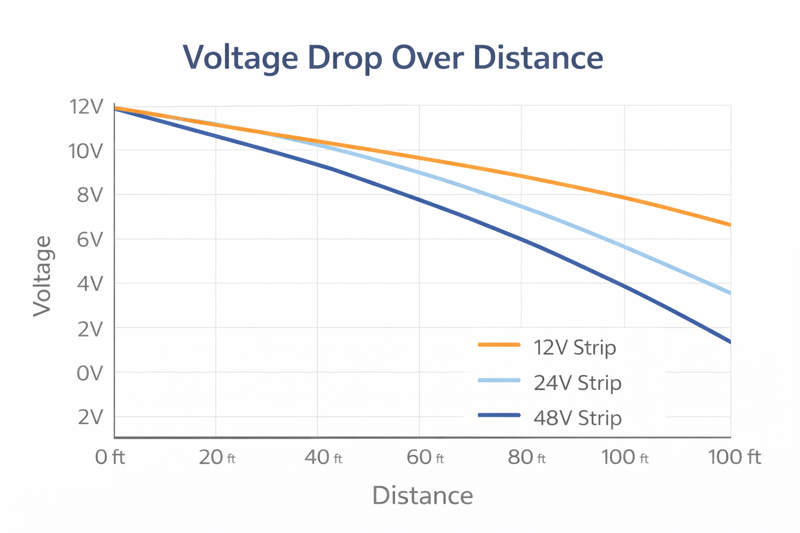

Voltage drop causes uneven lighting, making the end of your deck look dim and yellow. It turns a professional job into an amateur mistake when the lights don’t match.

For runs over 5 meters, 12V generally fails. Standardize on 24V or 48V systems. These professional voltages maintain consistent brightness across long perimeters, reducing wiring complexity and potential failure points.

Engineering the Power Run

One of the biggest pain points for installers is cabling. If you use a 12V strip for a 10-meter deck railing, you have to run power wires to the start, and likely the middle or end, just to keep the brightness even. This means more labor and more waterproof joints to hide.

The Solution Hierarchy:

- Standard 12V: We offer these, usually for short runs or intricate integrated joinery where cut points need to be tiny. The cut length is often around 25mm. This is great for small cabinets, but bad for long decks.

- Professional 24V: This is the industry standard for commercial and high-end residential work. The higher voltage pushes the current further. Our 24V5 COB strips have a cutting length of 50mm. This is still small enough for precision fitting but allows for much longer single runs without dimming.

- Industrial 48V: For massive exterior perimeters or commercial patios, we provide 48V Constant Current strips. These are designed for "Extra long" runs. You can light an entire pool perimeter from one power source.

Always choose 24V as your baseline for decks. It balances run length with safety. It allows you to use thinner gauge wire or run your wires further from the transformer without significant loss. Also, ensure you match your power supply wattage6 to the strip. Our 24V strips typically consume 10W to 15W per meter depending on the brightness needed. Always leave a 20% headroom on your power supply longevity.

| System Voltage | Cut Increments | Typical Max Run | Best For |

|---|---|---|---|

| 12V DC | ~25mm | < 5 Meters | Small detailed steps |

| 24V DC | ~50mm | 10 Meters | Standard Decks & Railings |

| 48V DC | ~33.3mm | > 20 Meters | Large Commercial Patios |

Conclusion

Deck lighting is about safety and atmosphere. By choosing IP68 Solid Extrusion for durability, COB technology for a seamless look, and 24V/48V systems for efficient installation, you differentiate yourself from the cheap competition. You deliver a project that looks professional and withstands the elements for years.

-

Explore this link to understand how Silicone Extrusion enhances durability and performance in outdoor lighting applications. ↩

-

Discover why IP68 is the gold standard for waterproofing, ensuring longevity and reliability in outdoor lighting solutions. ↩

-

Explore this link to understand how COB technology enhances lighting quality and efficiency, making it a game-changer in the industry. ↩

-

Learn about Ra90 and its significance in achieving superior color quality in lighting, especially for showcasing natural materials. ↩

-

Explore the advantages of 24V LED strips, including longer runs and better efficiency, to enhance your lighting projects. ↩

-

Learn how to select the appropriate power supply wattage to ensure optimal performance and longevity of your LED lighting. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

Event and Wedding LED Rope Lighting: Are Your Lights Ruining the “Big Day”?

Picture the scene: A bride spent thousands on her floral arrangements. The photographer is lined up for the perfect shot.…

Retail Display LED Rope Lighting: Is Your Lighting Scaring Away Customers?

We have all had that experience: walking into a retail store where the lighting feels harsh, clinical, or uneven. The…

Restaurant and Bar LED Rope Lighting Design Ideas: Is Your Ambience Killing Your Profits?

It is the oldest rule in the hospitality playbook: people don’t just pay for the food; they pay for the…