LED Rope Light Motifs: Are Your Holiday Decorations Stuck in the “Wireframe” Age?

Every November, I see the same thing at big-box hardware stores: flimsy white wireframes wrapped with cheap, sparse ministring lights. You plug them in, and from the street, they look like a blurry, disconnected mess. If you are a professional installer or a business owner creating displays for clients, you cannot charge a premium for that "dollar store" look.

To build commercial-grade holiday motifs that command high prices, you must transition to custom aluminum frames outlined with High-Density COB Neon Flex. By utilizing silicone-encased strips with "no dark area" technology and precision cut points, you can create seamless, solid-light figures—snowflakes, reindeer, or logos—that look like vibrant glass neon but survive the winter elements.

In my factory, we supply the raw engines—the LED neon flex—to some of the biggest holiday fabrication houses in the US. They don’t buy pre-made Santa Claus figures; they buy our 24V cutting-edge strips and build the art themselves. Let’s dive into the specs you need to start fabricating your own high-margin motifs.

Why Does "Dot-Free" Lighting Matter for Motifs?

When you build a small motif—say, a 2-foot snowflake—the viewer is often closer to the display than they would be to a roofline. If you use standard tape light, the individual LED dots are painfully visible. It breaks the illusion of the shape.

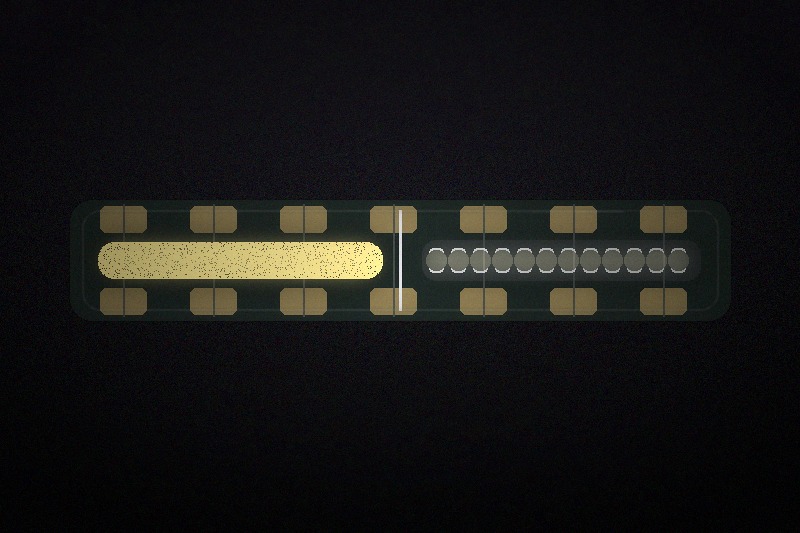

You need to source High-Density COB (Chip-On-Board) flexible strips, specifically those with 320 to 512 LEDs per meter. These strips cover the phosphor layer completely, ensuring "no dark areas" and High Light Transmittance, creating a continuous, soft line of light that defines your shape perfectly without the "bead particle" look of older LEDs.

The Density Equation

In the world of motif fabrication, "pixelation" is the enemy.

The Technical Shift:

- Old Standard (SMD): Traditional motifs used rope light with LEDs spaced 1 inch apart. This looks jagged.

- The COB Solution: Our current COB technology packs 480 LEDs per meter1. That is essentially one LED every 2 millimeters.

- Visual Impact: According to our technical data, this high density results in "no sense of LED bead particles, nor any dark areas". When you wrap this around a metal frame, it looks like a glowing laser beam.

Brightness vs. Efficiency:

For a motif, you want glow, not a floodlight.

- Our COB strips are engineered for Soft Light.

- However, they are powerful. A 480 LED/m strip pushes between 100 to 110 Lumens per Watt. This means a simple 1-meter star motif emits roughly 500 lumens—bright enough to punch through a snowy lawn layout but diffused enough to be pleasant to the eye.

Color Consistency:

When building multiple motifs (e.g., a row of candy canes), the specific "Red" matters. Standard LEDs vary. Our manufacturing process ensures tight binning on colors, whether you are using static Red/Green or a specific 3000K warm white2. This consistency is what separates a professional display from a DIY garage project.

| Feature | Standard Rope Light | High-Density COB Neon |

|---|---|---|

| Appearance | Dotted, granulated | Solid, seamless line |

| LED Density | 30-60 per meter | 320-512 per meter |

| Light Quality | Harsh points of light | Soft, high transmittance |

| Aesthetic | Cheap/Temporary | Premium/Architectural |

How Tight Can You Bend Without Breaking the Light?

Building a motif involves tight curves. You are tracing the antlers of a deer or the loops of a bow. The number one failure mode in custom motifs is the installer forcing the light into a corner and snapping the internal copper PCB.

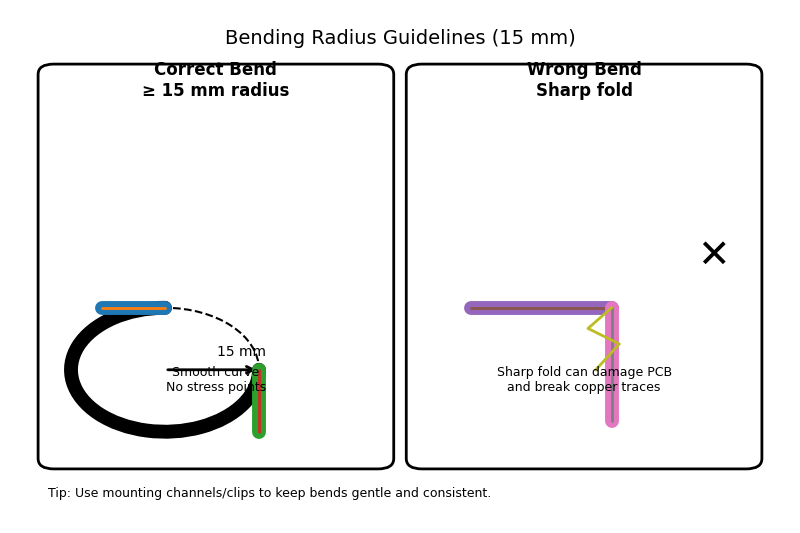

You must respect the Minimum Bending Diameter of R > 15mm. Our silicone neon flex is engineered for "excellent resistance to folding," but physics has limits; for sharp 90-degree corners on a frame, you should cut and solder the strip rather than forcing a bend that violates the 15mm radius rule to ensure longevity.

The Physics of the Bend

I have seen beautiful motifs ruined because the builder treated the LED strip like a piece of wire. It is a circuit board.

The "Do Not Fold" Rule:

Our datasheets utilize bold warnings: "Please do not fold it in half" and ensure "Bending diameter: R > 15mm3".

- The Risk: If you fold the strip onto itself (like creasing a piece of paper), you detach the COB chip from the PCB. The light will die instantly or flicker later when the temperature drops.

- Application Strategy: When designing your aluminum frame, use rounded corners. If your design requires a razor-sharp point (like a 5-point star), do not bend the light around the tip. stop the light, cut it, and solder a jumper wire to start the next segment.

Material Matters:

We use FPC (Flexible Printed Circuit) with double-sided copper .

- This copper adds durability, but it also has a "grain."

- Direction: You must know if you are buying "Top Bend" or "Side Bend" (Neon). Most of our COB strips function as a flat ribbon. You cannot bend them "horizontally" (sideways) flat on a table. For motifs where the light faces outward, the strip must flex up and down (Top Bend) or use a specialized Side-View neon tube.

Durability in Cold:

The silicone housing is key here. Unlike PVC which cracks when bent in freezing temps, our IP65/IP67 double-color silicone4 stays flexible. This allows the motif to be stored in a hot garage in July and deployed in freezing December without the casing shattering.

How Do You Handle Intricate Designs with Small Frames?

If you are building a small, intricate motif—like a "Script" word or a detailed snowflake, standard wide LED strips look clunky. They don’t fit into narrow channels, and the cut points are too far apart, leaving you with dark overhangs.

Switch to "Nano" style strips with a 4mm or 5mm PCB width and short cutting units. Using a 12V system allows for cutting lengths as precise as 25mm (1 inch), and the ultra-slim 4mm profile fits into delicate wireframes or thin acrylic channels where standard 10mm strips simply cannot go.

The Precision of Miniaturization

For large building outlines, big hefty strips are fine. For custom motifs, you need surgical precision.

The 4mm Advantage:

We manufacture a specialized line of 4mm PCB width5 COB strips.

- Comparison: Standard strips are 10mm or 12mm wide . A 4mm strip is vanishingly small.

- The Fit: This allows you to weld a framing channel that is only 5-6mm wide. The lighting element becomes almost invisible when turned off, highlighting the negative space of your design.

The Cut Length Logic:

You cannot have a 2-inch dark spot on a 10-inch reindeer leg.

- 12V vs 24V: Physics dictates that lower voltage allows for shorter cut points.

- Our 24V COB strips6 typically cut every 50mm.

- Our 12V COB strips cut every 25mm or even less on some models.

- Why it matters: On a custom motif, you often need to terminate the light exactly at the end of a strut. A 25mm (1 inch) cut unit means you can tailor the light to the frame with 98% accuracy.

Powering Small Frames:

Using 12V for motifs is usually superior to 24V.

- Since motifs are small (usually under 5 meters of light total), voltage drop is not an issue.

- You gain the advantage of the shorter cutting unit without sacrificing brightness.

| Spec | Standard Strip | Motif-Grade Nano Strip |

|---|---|---|

| PCB Width | 10mm / 12mm | 4mm |

| Cut Length | 100mm (4 inches) | 25mm (1 inch) |

| Voltage | 24V (Long run) | 12V (Precision) |

| Best For | House Roofline | Intricate Figures |

Can You Make Your DIY Motifs Move?

Static white snowflakes are classy, but customers today want TikTok-worthy displays. They want the snowflake to "grow" from the center out, or the reindeer to look like it is running.

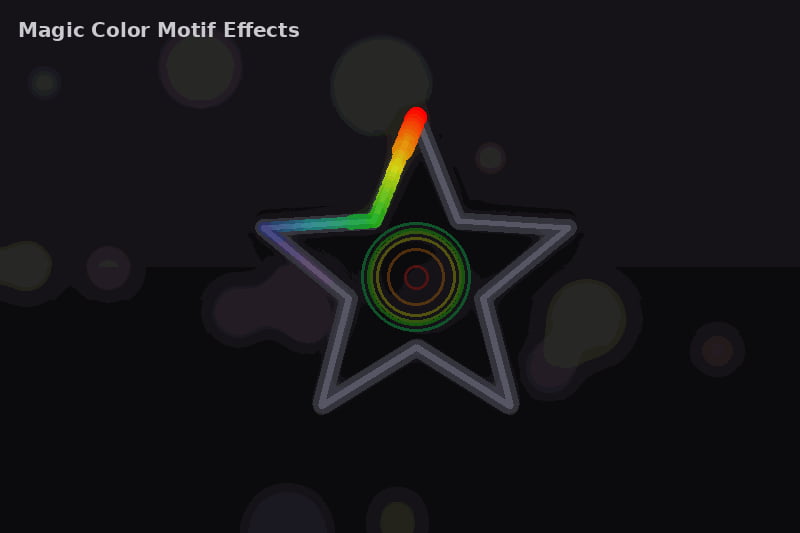

Integrate "Magic Color" (RGB+IC) COB strips. With an astounding density of 720 LEDs per meter and IC chips embedded directly in the line, you can program complex flowing effects that turn a stationary wireframe into a dynamic animation without seeing any pixel gaps.

Addressable Tech for Motifs

This is the upsell that doubles your profit margin.

The Hardware Specs:

You are looking for RGB+IC7 (Integrated Circuit).

- Density: We produce a specific 720 LEDs/m Magic Color COB strip . This is the highest density on the market for digital control.

- Control: The IC (chip) controls a "pixel" or "segment." In our 12V version, a pixel is often 50mm long. In 24V, it might be 100mm.

- The Effect: Because the LEDs are so dense (720/m), the color mixing is perfect. When you run a "meteor" effect, it looks like liquid light pouring through your frame.

Patterning for Motifs:

Imagine a "Star" motif.

- Wiring: If you wire the data line properly from the center outwards, you can program an "explode" effect.

- Controller: You need a controller compatible with WS2811 / UCS2904 protocols8. Simple Bluetooth controllers can trigger widespread patterns like "Rainbow," "Fire," or "Stacking."

Power Warning:

Magic Color draws power.

- A 720 LED/m strip is rated at 12 Watts to 24 Watts per meter.

- If you build a large Santa motif using 10 meters of this strip, that is a 240W load. You cannot use a tiny wall-wart adapter. You need a dedicated waterproof power supply (like a Mean Well HLG).

How Do You Ensure Your Custom Build Survives Wet Snow?

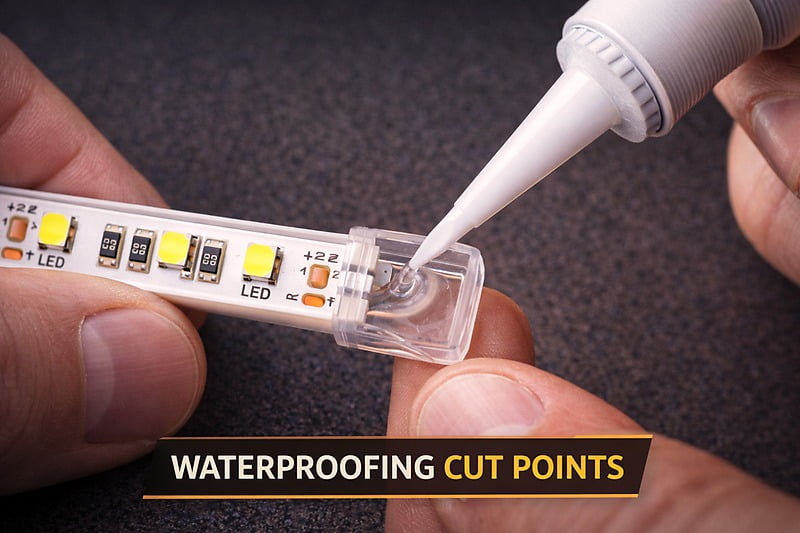

You built a beautiful frame, soldered the lights, and installed it. Two weeks later, it trips the GFCI breaker. Why? Because water got into your hand-soldered connections.

You must waterproof your cut points using silicone end caps and neutral sealant, matching the IP67 factory rating of the strip. Never rely on electrical tape; use heat-shrink tubing filled with dielectric grease or silicone glue over every solder joint to maintain the integrity of the double-color silicone extrusion.

The IP Rating Reality

The strip itself comes from our factory rated IP67 or IP68 . This means it can handle rain and temporary submersion. However, once you cut it, you have destroyed that rating.

Restoring the Seal:

- The Cut: When you cut a IP67 Hollow Silicone or Double-Color Silicone strip, you expose the copper PCB.

- The Fix: You must use the specific end-caps provided with the strip.

- Fill the cap with Neutral Silicone Sealant (Acidic sealant creates corrosion on the copper).

- Push the cap on and let it cure for 24 hours.

- The Lead Wire: The weak point is where the wire enters the strip. Use glue-lined heat shrink tubing over this junction.

Why "Double-Color" Silicone?

We highlight "double-color silicone" in our IP65/IP67 products.

- This isn’t just aesthetic. The white bottom layer reflects light upwards, increasing efficiency.

- The clear/milky top layer diffuses the light.

- Because they are co-extruded (molded together hot), they never delaminate. If you buy cheap strips where the tube is separate from the LED, water will get in between the layers and freeze, popping the tube open.

Pro Tip: For motifs that sit on the ground (like grazing deer), mount the connection points up high on the frame if possible, away from standing puddles of melting snow.

Conclusion

Building your own holiday motifs allows you to offer something store-bought competitors can’t: high-impact, custom-designed art. By selecting High-Density COB (480-720 LEDs/m) for a seamless look, utilizing 4mm "Nano" PCBs for precision fit, respecting the 15mm bend radius, and sealing your work to IP67 standards, you transform raw materials into high-value seasonal assets. Don’t just hang lights this year; build the show.

-

Explore how 480 LEDs per meter enhance lighting quality and visual appeal in various applications. ↩

-

Learn about the advantages of 3000K warm white lighting for creating a cozy and inviting atmosphere. ↩

-

Understanding bending diameter is crucial for maintaining LED strip functionality and longevity. ↩

-

Explore how IP65/IP67 silicone enhances durability and flexibility in extreme temperatures for LED applications. ↩

-

Explore this link to understand how 4mm PCB width enhances design precision and aesthetic appeal in lighting. ↩

-

Discover the differences between 24V and 12V COB strips to make informed choices for your lighting projects. ↩

-

Explore this link to understand RGB+IC technology, which is crucial for achieving high-quality LED effects. ↩

-

Learn about WS2811 and UCS2904 protocols to enhance your LED control and programming capabilities. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

Event and Wedding LED Rope Lighting: Are Your Lights Ruining the “Big Day”?

Picture the scene: A bride spent thousands on her floral arrangements. The photographer is lined up for the perfect shot.…

Retail Display LED Rope Lighting: Is Your Lighting Scaring Away Customers?

We have all had that experience: walking into a retail store where the lighting feels harsh, clinical, or uneven. The…

Restaurant and Bar LED Rope Lighting Design Ideas: Is Your Ambience Killing Your Profits?

It is the oldest rule in the hospitality playbook: people don’t just pay for the food; they pay for the…