LED Rope Lights for Business Signage and Storefronts: Is Your Storefront Saying “Cheap” Before Customers Even Enter?

We have all driven past that one strip mall at night. You know the one—where the "Open" sign is flickering ominously, and the architectural lighting highlights the building’s flaws rather than its features. As a business owner or a signage contractor, you understand that your storefront is your silent salesman. If your lighting looks cheap, pixelated, or broken, customers assume your service is too.

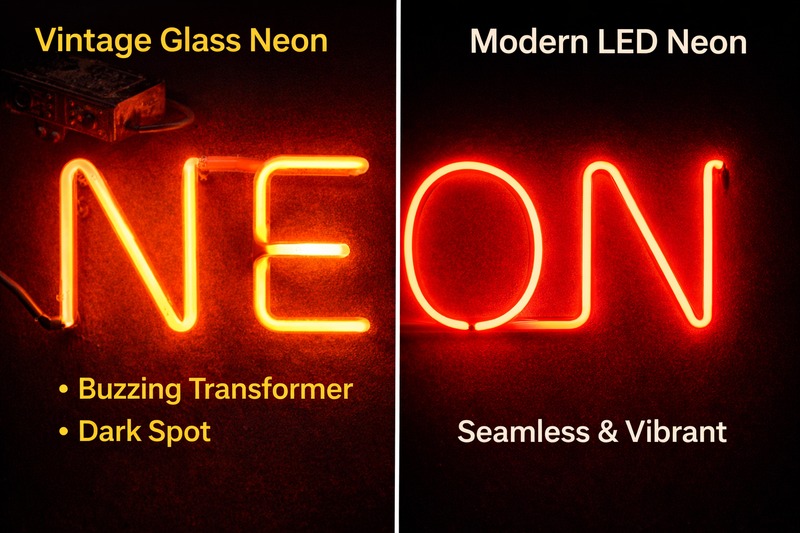

To create commercial signage and storefront outlines that project professionalism and command attention, you must abandon old-school glass neon and first-generation LED tubes in favor of High-Density COB LED Neon Flex. By utilizing silicone-encased strips with 4mm ultra-narrow PCBs and "dot-free" phosphor technology, you can fabricate crisp, legible logos and architectural accents that are virtually indistinguishable from traditional neon but with superior durability and 70% lower energy costs.

In my factory, we supply the raw LED engines to some of the largest signage fabrication houses in North America. They aren’t buying standard tape light; they are buying specific engineering solutions designed to handle the rigors of outdoor branding. Let’s explore the technical specifications you need to turn your storefront into a beacon.

The transition from glass to LED is not just about saving money on the electric bill; it is about expanding your creative capabilities. Modern manufacturing allows us to bend light in ways glass blowers never could. However, executing this correctly requires understanding the difference between "decorative" holiday lights and "architectural" signage components.

Why Does "Dot-Free" Lighting Matter for Brand Integrity?

If you are replicating a corporate logo, "pixelation" is the enemy. Standard LED rope lights create a "string of pearls" effect where individual light dots are visible. This looks festive for a Christmas tree but unprofessional for a law firm or a high-end boutique.

You need to source High-Density COB (Chip-On-Board) flexible strips, specifically those boasting 320 to 512 LEDs per meter. These strips cover the LED chips with a continuous yellow phosphor layer, ensuring "no dark areas" and high light transmittance. This creates a solid, laser-like line of color that ensures your brand’s font matches its digital design exactly, without the jagged distraction of individual light points.

The Density and Uniformity Equation

When we manufacture lights for signage, we focus on "optical continuity1."

The Problem with Old Tech:

Traditional SMD (Surface Mounted Device) strips usually have 60 or 120 LEDs per meter. Even with a milky diffuser cover, if you look closely, you see hot spots. For a sign that might be viewed from a sidewalk five feet away, these hot spots break the illusion of the "neon" glow. It looks like a craft project, not a business fixture.

The COB Solution:

Our COB technology packs up to 480 or even 512 LEDs into a single meter. That is roughly one LED every 2 millimeters. Because they are so close together, and covered by a singular phosphor layer, the light blends immediately at the source.

- Visual Impact: There is no sense of "bead particles." It creates a fluid look.

- Brightness Efficiency: You might assume more chips mean more power, but COB chips are efficient. We can achieve high luminous flux (brightness) while keeping the heat low.

- Application: This is critical for "stroke" lighting. If your sign features a thin font, a COB strip inside a silicone tube makes the letter immediately legible. With spotted lights, the brain has to "connect the dots" to read the word, which slows down brand recognition.

The Diffuser Factor:

With old LEDs, you needed a thick, heavy silicone cover to blur the dots, which reduced brightness. With COB, because the light is already uniform, we can use "High Light Transmittance2" silicone. This implies your sign is brighter and punches through the darkness better, enticing customers from further down the street.

| Feature | Standard Rope Light | High-Density COB Neon |

|---|---|---|

| Appearance | Dotted, granulated | Solid, fluid line |

| LED Density | 60-120 per meter | 320-512 per meter |

| Readability | Poor for text | Excellent for text |

| Aesthetic | Temporary/Festive | Permanent/Architectural |

How Do You Handle Intricate Fonts and Logos?

Business logos are rarely simple squares. They have sharp angles, serifs, and cursive scripts. Standard wide LED strips (10mm or 12mm) cannot bend tightly enough to follow these contours without snapping or bulky overlap.

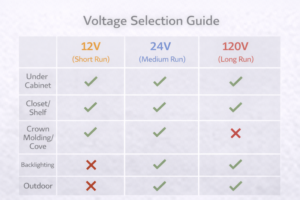

Switch to "Nano" style strips with a 4mm or 5mm PCB width and ultra-short cutting units. A 12V system enables cutting lengths as precise as 25mm (1 inch), and the ultra-slim 4mm profile fits into narrow routed channels in acrylic or aluminum, allowing you to trace delicate script fonts or complex icon details that standard strips simply cannot achieve.

The Geometry of Signage

In signage fabrication, the "Minimum Bending Radius3" and "Cutting Unit" are the two most critical specs on the datasheet.

The 4mm Advantage:

Most standard strips are 10mm wide. If you are trying to illuminate a channel letter where the stroke width is only 15mm, a 10mm strip leaves no room for error or wire modulation.

- The Fit: We manufacture COB strips with a 4mm PCB width4. This is incredibly narrow. It allows sign makers to route very thin channels in acrylic backing.

- Negative Space: This precision allows you to maintain the "negative space" in letters like "e" or "a". With bulky strips, the center of the "e" gets swallowed by light, making the text look like a blob.

The Cut Length Logic:

Imagine you are lighting the letter "I" in a serif font. The vertical stroke is 13cm long.

- The Waste: If your strip has a cut point every 10cm (common in 24V SMD), you have to cut at 10cm (leaving a 3cm dark spot) or 20cm (leaving 7cm of strip you have to hide or tape off).

- The Fix: Our 12V COB strips often have cut points every 25mm (approx 1 inch) or less. For that 13cm stroke, you cut at 12.5cm. The lighting fits perfectly.

- Voltage Trade-off: While 24V is better for long building runs, 12V is superior for intricate signs because lower voltage allows for these shorter cutting intervals.

Bend Radius Warning:

Even with flexible COB, you must respect the physics of copper. The bending diameter should generally stay above 15mm. For sharp 90-degree corners in a logo (like a square box), professional fabricators don’t force the bend; they cut the strip and solder a tiny jumper wire. This ensures the PCB doesn’t crack over time due to thermal expansion.

Is Your Brand Color Actually Accurate?

If your brand color is "Coca-Cola Red," it cannot be orange-red or pink-red. It must be specific. Cheap LED signage often has poor color rendering or inconsistent "binning," where one section of the sign looks slightly different from another.

You must specify LED strips with tight chromaticity binning and a High Color Rendering Index (CRI), ideally Ra90. This ensures that the light emitted renders colors truthfully and matches your brand guidelines exactly, while high-quality double-side oxidized copper PCBs ensure that the color remains consistent from the beginning of the run to the end without voltage drop causing a "pink shift."

Calculated Color Science

Color isn’t just aesthetic; it’s trademarked.

The Binning Process:

In LED manufacturing, we sort chips into "bins" based on slight variations in color output.

- Cheap Suppliers: They buy wide bins. You might get a "Warm White" that ranges from 2800K to 3200K in the same order.

- Professional Grade: We ensure tight variance. If you order 3000K, you get a clean, consistent gold. For colored lights (Red, Green, Blue), we stick to specific nanometer wavelengths (e.g., Red at 620-625nm).

CRI (Color Rendering Index5) in Retail:

This matters immensely for storefront windows.

- The Low CRI Effect: Standard LEDs often have a CRI of 70. This makes products in the window look dull. Skin tones look grey. Food looks unappetizing.

- The Ra90 Difference: Our COB strips are rated Ra90. If you use these to outline your storefront window, the light spilling onto your merchandise makes the colors pop. A clothing store, bakery, or florist needs this high fidelity to sell product.

Voltage Drop and Color Shift:

Have you ever seen a long white LED strip that looks bright white at the start but turns yellow/dim at the end? That is voltage drop.

- The Physics: As power travels down the strip, resistance lowers the voltage. Lower voltage changes the color output of the LED.

- The Solution: We use Double-Sided Copper PCBs6 (Flexible Printed Circuits). The extra copper acts as a highway for electrons, reducing resistance. For large building outlines, we recommend 24V Constant Current designs which can run 10 to 15 meters with zero color shift.

Can Your Sign Survive the Parking Lot Environment?

Outdoor signage faces UV radiation, rain, freezing snow, and heat. PVC materials use in cheap rope lights turn yellow and brittle within six months.

Transition to IP67 or IP68 Silicone Extrusion housings. Unlike PVC, silicone is chemically stable and UV resistant, meaning it will not yellow or crack after years of sun exposure. IP68 solid extrusion fills the tube completely with silicone, eliminating any air gaps where condensation could form, providing the ultimate protection for storefronts exposed to heavy rain or snow.

Material Science for Longevity

When you install a sign, you don’t want to rent a bucket truck six months later to fix it.

- PVC: It’s cheap plastic. Sunlight (UV) breaks its chemical bonds. It turns brown/yellow, which filters your blue light into a gross green. In winter, it freezes hard and cracks if the building vibrates.

- Silicone: It is an inorganic polymer. It ignores UV light. It stays flexible from -40°F to 400°F.

- Double-Color Injection: For neon effects, we use a "double-color" extrusion. The bottom half is white (to reflect light up) and the top is translucent or colored (to diffuse light). Because these are molded together while hot, they never delaminate.

- IP65 (Splash proof): Okay for under an awning.

- IP67 (Hollow Extrusion): Great for rain. The strip is inside a silicone tube. However, if air gets in, condensation can fog up the tube.

- IP68 (Solid Extrusion / Potting): We fill the entire tube with silicone glue. The LED is practically fossilized inside. Water cannot get in because there is no air gap. This is the gold standard for low-level landscaping or signs that might get blasted by snow blowers.

Thermal Management:

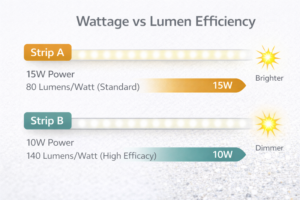

Heat kills LEDs. Silicone conducts heat better than PVC/Epoxy. Combined with our efficiency (up to 110-140 Lumens per Watt), the heat escapes the strip quickly, preserving the phosphor and ensuring the sign stays bright for 30,000+ hours.

How Do You Catch the Eye in a Crowded Street?

A static light is nice; a moving light is impossible to ignore. Modern storefronts are competing for attention in a visual jungle.

Integrate "Magic Color" (RGB+IC) technology. By using strips with embedded IC chips, you can program dynamic effects like "rainbow flow," "meteor chases," or "breathing" colors. With high-density 720 LED/m options, these effects look like digital liquid flowing through your sign, grabbing peripheral vision far more effectively than a static neon tube.

Addressable Branding

This isn’t about turning your store into a disco; it’s about programmable visibility.

The Tech Stack:

- RGB+IC: This stands for Red-Green-Blue + Integrated Circuit.

- Protocols: Common chips like WS2811 or UCS2904 allow you to control "pixels."

- Resolution: In our 12V Magic Color strips, a "pixel" might be 50mm long. In high-density 5V options, every single LED can be a pixel.

- Signage Application: Imagine a coffee shop. You can program the light to look like dark coffee pouring (brown/white gradient moving down). Or a barber shop pole effect (Red/White/Blue spinning).

The Controller:

You don’t need a degree in coding. Modern Bluetooth/Wi-Fi controllers allow business owners to select modes from a phone app.

- Holiday Mode: One click, and the store outline turns Red/Green for December.

- Sales Mode: Flashing Red/White to draw attention to a "Sale" poster.

Power Consideration:

Magic Color draws more power when running full white. However, running "chasing" effects actually saves energy because LEDs are off 50% of the time during the cycle. It is high impact, lower operational cost.

| Effect | Impression | Business Use Case |

|---|---|---|

| Static White | Professional, Clean | Law Firm, Clinic |

| Static Color | Branded, Bold | Pizza Shop (Red), Gym (Blue) |

| Breathing | Alive, Calm | Spa, Yoga Studio |

| Chasing/Meteor | Urgent, High Energy | Bar, Vape Shop, Tech Store |

Conclusion

Your storefront signage is the face of your business. Using outdated, dotted rope lights is like showing up to a meeting in a stained shirt. By upgrading to High-Density COB Neon, leveraging 4mm precision PCBs for detailed logos, insisting on CRI90 for color truth, and protecting your investment with IP68 Silicone, you build a brand presence that screams quality. Stop settling for "good enough" lighting; build a display that customers can’t look away from.

-

Exploring optical continuity will help you grasp its importance in creating seamless and professional lighting solutions. ↩

-

Understanding High Light Transmittance can enhance your knowledge of LED efficiency and brightness, crucial for effective signage. ↩

-

Learn why respecting the Minimum Bending Radius is crucial for maintaining the integrity and longevity of signage materials. ↩

-

Explore this link to understand how a 4mm PCB width enhances design flexibility and precision in signage fabrication. ↩

-

Understanding CRI is crucial for enhancing product visibility and appeal in retail settings. ↩

-

Explore how these PCBs can improve LED performance and reduce color shift in lighting applications. ↩

-

Explore the advantages of silicone in various applications, especially its durability and flexibility compared to other materials. ↩

-

Understanding waterproofing grades is crucial for selecting the right materials for outdoor projects, ensuring longevity and performance. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting…

IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…