LED Strips vs. LED Tape vs. Rope Lights: Which One Do You Actually Need?

Your client is confused. They’ve heard three different terms—LED strips, LED tape, and rope lights—used to describe what seems like the same thing. They’re trying to specify the right product for a project, but they’re worried they’ll choose the wrong one, ending up with a product that’s too dim, too bulky, or just unprofessional.

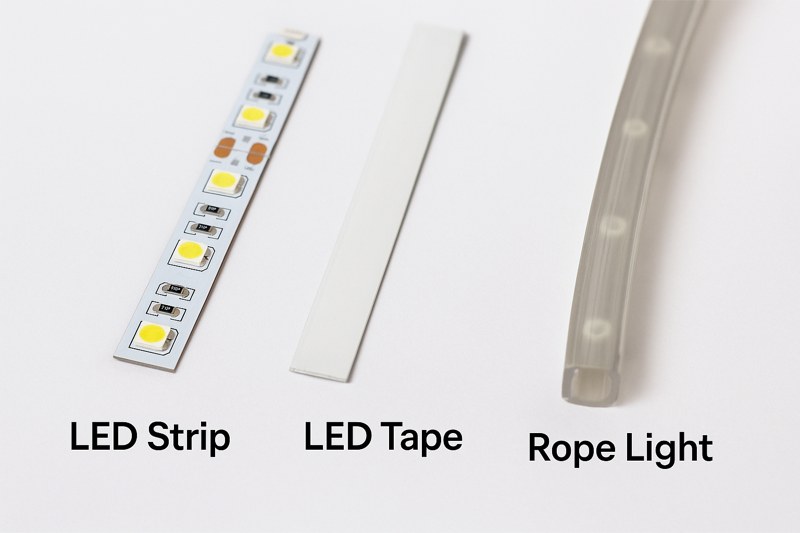

While "LED Strip" and "LED Tape" are often used interchangeably for the same flat, flexible circuit board product, "Rope Light" refers to a distinctly different, older technology: LEDs encased in a thick, round plastic tube. Choosing the right one is critical for professional results.

From my factory floor, I see the real-world impact of this confusion. A designer specifies "LED rope light" for a sleek, modern architectural cove, when what they really need is a low-profile LED strip. The wrong choice can ruin a design. That’s why getting the terminology right is the first step in any successful lighting project. I want to clear this up once and for all, not just to define the terms, but to explain why it matters for a professional like Tom who needs to deliver the right product for the job. Let’s break down what each term means and where each product truly belongs.

What Exactly Are LED Strips and LED Tape?

A potential client sends you a spec sheet asking for "LED tape." Then another one sends a request for "LED strips." They both want to create a seamless line of light under a cabinet. Are they asking for two different things?

No, they are asking for the same product. "LED Strip" and "LED Tape" are professional and colloquial terms, respectively, for a flexible printed circuit board (FPC) with surface-mounted LEDs. They are thin, flat, and typically come with an adhesive backing for easy mounting.

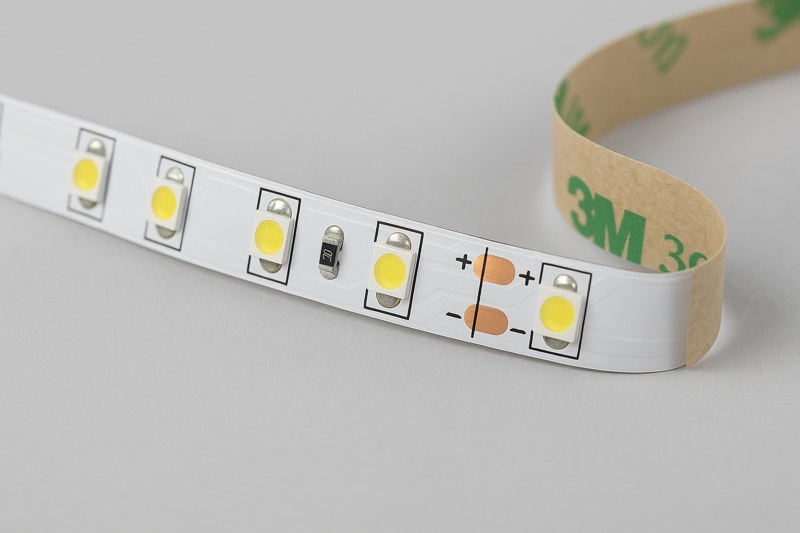

This is the most important clarification: LED Strip = LED Tape. In the industry, we typically use the term "LED Strip" or "Flexible LED Strip," as it’s a more technical description of the product’s form—a strip of circuitry. "LED Tape" became a popular nickname because most of these strips come with a 3M adhesive backing, making them as easy to apply as tape. They are the modern, versatile, and professional standard for a huge range of applications, from architectural lighting to task lighting. They offer the highest efficiency, the best color quality options (high CRI), and the most advanced control capabilities (like DMX addressability). As a factory, this is the product we specialize in manufacturing because it offers the performance our clients demand.

A Deeper Dive into the Professional LED Strip

Understanding the characteristics of a professional-grade LED strip is what separates a high-quality installation from a cheap one.

-

The Anatomy of a Modern LED Strip:

- Flexible Printed Circuit Board (FPC)1: The flat, flexible base. The quality of the copper in the FPC is critical for conducting electricity efficiently and managing heat. We use a thick, high-quality copper base to ensure minimal voltage drop and a long lifespan.

- Surface Mount Devices (SMDs)2: These are the LED chips themselves. They come in various sizes (e.g., 2835, 5050, 3528) which relate to their dimensions and typically their brightness and power consumption.

- Resistors: Each small segment of the strip has resistors to regulate the voltage going to the LEDs.

- 3M Adhesive Backing3: A high-quality adhesive is non-negotiable for a professional installation that won’t peel off over time.

-

Why Professionals Choose Strips/Tape:

- Low Profile: They are incredibly thin and can be hidden in tiny coves, under ledges, or within custom fixtures.

- High Performance: They offer a massive range of brightness levels (lumens), from gentle accent lighting to powerful primary illumination.

- Superior Light Quality: This is where we excel. We can produce strips with a high Color Rendering Index (CRI of 90, 95, or even 98), ensuring that colors under the light look true and vibrant. This is essential for retail, gallery, and high-end residential projects.

- Versatility: They are available in a huge variety of single colors, tunable white (CCT), RGB, and addressable pixel versions.

| Feature | Professional LED Strip / Tape | Why It Matters to a Pro |

|---|---|---|

| Form Factor | Thin, flat, flexible circuit board | Can be hidden easily; conforms to curved surfaces. |

| Light Quality | Excellent (High CRI & R9 values available) | Renders colors accurately, crucial for retail and architectural use. |

| Brightness Options | Very Wide Range (from 100 to 3000+ lumens/meter) | Perfect for any application, from subtle accents to bright task light. |

| Control | Advanced options (Dimmable, CCT, RGB, DMX/Pixel) | Allows for full integration into smart systems and dynamic scenes. |

| Primary Application | Architectural & Commercial Grade Lighting | This is the go-to product for high-quality, reliable installations. |

What is a Rope Light, and Is It Ever a Good Choice?

Now your client has an outdoor patio project. Someone suggested using "LED rope lights" to line the deck railing because they are waterproof and cheap. You look at them and see a thick, round, plastic tube with dim-looking lights inside. Is this the right tool for a professional job?

An LED rope light is a much older, simpler technology where LEDs are placed inside a round, hollow PVC tube. While durable and inexpensive, they suffer from significantly lower brightness, poor light quality, and a bulky, dated appearance compared to modern LED strips.

Think of rope light as the predecessor to the modern LED strip. In its day, it was a great solution for decorative outdoor and holiday lighting. The thick plastic tube provides decent waterproofing and protection, making it very durable. However, the technology is now largely obsolete for professional architectural or commercial work. The light it produces is often dim and "spotty," where you see the individual dots of light rather than a smooth glow. The PVC tubing can also yellow and become brittle when exposed to direct sunlight over time. While we could manufacture rope lights, we choose not to, because we focus on providing high-performance lighting solutions, and rope light simply doesn’t meet that standard for the vast majority of professional applications.

A Deeper Dive into Rope Light’s Limitations

Understanding why rope light is the wrong choice for most professional jobs helps you guide your clients to a better solution, like a waterproof, IP67 or IP68 rated LED strip.

-

Outdated Design:

- Bulky Profile: The round shape, often 1/2 inch (13mm) in diameter, makes it impossible to hide. It is always a visible, bulky element rather than an integrated source of light.

- Limited Bending: Rope light can only bend on one axis (up and down). It cannot make flat, sharp turns, making it very difficult to cleanly outline shapes. A flexible LED strip can bend and turn much more easily.

- Visible Dots: The spacing of the LEDs inside the tube is wide, creating a very "dotty" or "spotty" appearance. It does not produce a clean line of light.

-

Poor Performance:

- Low Efficacy4: Rope lights are very inefficient. They produce far fewer lumens per watt than a modern LED strip.

- Poor Light Quality: The CRI of a typical rope light is very low, often below 80. This makes colors look dull and washed out.

- No Advanced Control5: You typically cannot get rope lights in tunable white, RGBW, or addressable pixel versions. Control is a simple on/off or basic dimming at best.

| Feature | LED Rope Light | Professional LED Strip / Tape (IP67 Waterproof6 Version) |

|---|---|---|

| Form Factor | Thick, round, bulky PVC tube | Thin, flat, low-profile silicone extrusion |

| Light Quality | Poor (Low CRI7, spotty appearance) | Excellent (High CRI, smooth and even light options) |

| Brightness Options | Very Limited (Typically low brightness only) | Very Wide Range (From low to very high output) |

| Control | Basic (On/Off, maybe simple dimming) | Advanced (Dimmable, CCT, RGB, DMX/Pixel) |

| Primary Application | Temporary decorative/holiday lighting | Permanent architectural & commercial grade lighting |

For that client with the outdoor patio, the vastly superior solution is a professional, IP67-rated, fully extruded silicone LED strip. It will provide a much brighter, cleaner, and more modern look while being just as durable and waterproof.

Conclusion

Clarity is key. "LED Strip" and "LED Tape" describe the modern, versatile, high-performance product for professional lighting. "Rope Light" describes an older, bulkier, and lower-performance technology best left for temporary decorations. Choosing the right product ensures your project looks professional, performs reliably, and stands the test of time.

-

Explore this link to understand how FPCs enhance LED strip performance and longevity. ↩

-

Discover how SMDs impact the brightness and efficiency of LED strips. ↩

-

Find out how 3M adhesive ensures a secure and durable installation for LED strips. ↩

-

Understanding low efficacy in rope lights can help you choose more efficient lighting solutions for your projects. ↩

-

Discover advanced control options to elevate your lighting design and provide more versatility in your projects. ↩

-

Learn about the benefits of IP67 waterproof ratings to ensure durability and performance in outdoor lighting. ↩

-

Exploring the implications of low CRI can enhance your knowledge of light quality and its impact on color perception. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…