Roof Line and Eave LED Rope Lighting: Is Your Building Disappearing at Night?

You design stunning architectural lines, specific roof pitches, and custom eaves, yet once the sun sets, all that detail vanishes into darkness. Standard floodlights just flatten the building’s facade, washing out the texture you worked so hard to create.

To truly accentuate architectural contours, you need high-density COB LED linear lighting installed directly under the roofline. Unlike old-school string lights, 24V or 48V COB systems create a crisp, continuous "neon" stroke that defines the building’s edge without visible dots, while IP67 hollow silicone extrusions protect against shelter-based humidity.

In my experience supplying US contractors, I often see rooflines ruined by "Christmas light" effects—jagged, dotted lines that look temporary. Professional architectural accenting requires a different approach. Let’s dive into the specs you need to source for a permanent, high-end exterior finish.

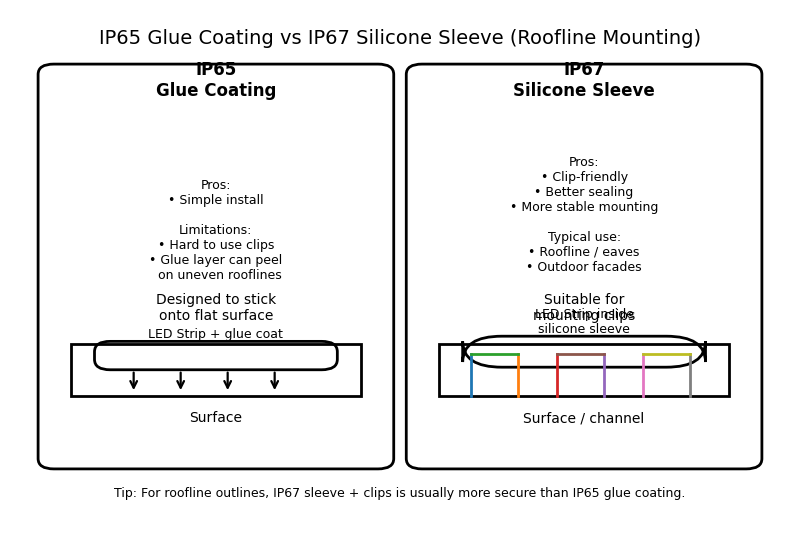

Why IP67 Is the Correct Standard for Eaves (Not IP65 or IP68)?

Choosing the wrong waterproofing for rooflines is the most common mistake. IP65 glue cracks in the sun, and IP68 solid extrusion is too heavy and expensive for upside-down mounting.

For under-eave and roofline applications, specify IP67 Hollow Silicone Extrusion. This lightweight sleeve protects against humidity and indirect rain while preventing the yellowing and cracking common with cheap IP65 coatings, ensuring your installation lasts for years.

The Weight and Heat Balance

When installing lighting 20 feet in the air, weight matters. If you use a heavy, solid-filled IP68 strip (which is designed for underwater or ground use), gravity will eventually fight your adhesive or clips.

Why We Manufacture IP67 for Heights:

- Hollow Structure: Our IP67 rating uses a hollow silicone tube. This provides a physical barrier against moisture without adding the heavy weight of solid silicone filling. It is lighter and easier for your installers to handle on a ladder.

- Heat Dissipation1: Rooflines trap heat. The hollow air gap in IP67 extrusion allows for slightly better thermal breathing compared to solid-packed IP68, which is crucial for longevity in hot summers.

- UV Stability: Unlike cheap IP65 "glue-dropped" strips that start yellowing after one season of UV exposure, our silicone sleeves remain clear.

I recently had a client in California insist on IP65 for a roofline because it was cheaper. I refused the order. IP65 uses a potting compound on the surface. Wind-blown dust sticks to it, and thermal expansion on a long roof run will crack that glue within months. Always request IP67 Hollow Extrusion2 for any architectural outline that isn’t sitting in a puddle.

| Rating | Method | Pro | Con for Roof |

|---|---|---|---|

| IP65 | Glue Drop | Cheap | Cracks, collects dust, yellows |

| IP67 | Hollow Tube | Lightweight, Clean finish | Perfect for Eaves |

| IP68 | Solid Fill | Submersible | Too heavy, overkill cost |

How Do You Get Straight Lines on Long Roof Spans?

Nothing looks worse than a "wobbly" light line on a straight modern roof. Flexible strips are great, but they can look messy if not tensioned or channeled correctly.

Use aluminum mounting channels in conjunction with COB LED strips. The rigid channel ensures a laser-straight architectural line, while the high-density COB strip provides a seamless "no dark area" output that looks like a fixed architectural element rather than a taped-on accessory.

The "Neon" Effect Without the Glass

Architects love the look of neon tubing but hate the fragility and high voltage. We solve this with COB (Chip on Board)3 technology.

The COB Advantage:

By mounting 320 to 480 LEDs per meter directly to the PCB, we create a solid line of light. There is "no sense of LED bead particles". When you place this inside an aluminum profile with a diffuser cover, it looks identical to a neon tube but is unbreakable.

Installation Tips for Your Crew:

- Bend Radius: Even though these are flexible, treat them with respect. Our data sheet warns: "Bending diameter R > 15mm4" and "Please do not fold it in half". On roof peaks, use corner connectors or gentle loops; do not crimp the strip.

- Cut Points: Roof measurements are rarely perfect. Our COB strips have cut points as small as 50mm (24V) or even 33mm, allowing you to trim precisely to the edge of the fascia board without leaving a dark gap at the end.

| Feature | Old Rope Light | COB Strip + Channel |

|---|---|---|

| Straightness | Wavy, sags over time | Laser Straight |

| Visual | Dotted "Christmas" look | Uniform Architectural Line |

| Daytime Look | Visible ugly plastic tubing | Hidden sleek metal channel |

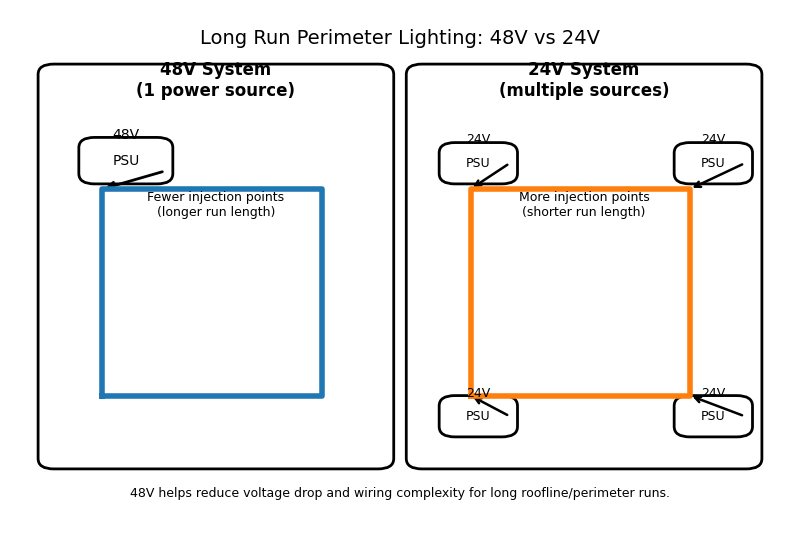

24V vs 48V: Minimizing Wiring at Heights?

Every time you have to run a new power feed, you need a junction box, a conduit penetration, and a waterproof seal. On a second-story roof, you want to minimize these penetrations.

Standardize on 24V for residential eaves, but switch to 48V Constant Current for commercial perimeters. A 48V system allows for continuous runs of over 65 feet (20m) from a single power source, significantly drastically reducing the number of power supplies and roof penetrations required.

The Cost of Voltage Drop

Labor is expensive. Sourcing checks usually focus on the price per foot of the light, but they ignore the installation cost. If you use 12V strip lights, you can only run about 16 feet (5m) before the light starts dimming.

The Rhstriplighting Recommendation for Exteriors:

- Residential (24V): For most homes, 24V is sufficient. It allows runs of roughly 32 feet (10m) without visible voltage drop. This matches well with typical facade lengths.

- Commercial (48V): For hotels or large warehouses, we offer distinct solutions. While our catalog highlights standard inputs, we engineer custom 48V solutions for these "Extra Long" needs.

Power Planning:

Always calculate your total load. Our high-density COB strips draw roughly 10W to 15W per meter5 depending on the model. Ensure your power supplies are weatherproof (IP67)6 if they are mounted externally, and try to centralize them in the soffit to keep the roof clean.

| Voltage | Max Continuous Run | Best Application |

|---|---|---|

| 12V | ~16 ft (5m) | Short dormers only |

| 24V | ~32 ft (10m) | Standard Home Eaves |

| 48V | ~65ft+ (>20m) | Commercial Building Wrap |

Are You Customizing the White Tone?

A modern grey house looks terrible with "yellow" 2700K light. A rustic timber home looks sickly with "hospital blue" 6000K light. You must match the light temperature to the building material.

Don’t guess the color. Utilize CCT (Correlated Color Temperature) Tunable COB strips. These dual-white chips allow you to adjust the lighting from warm 2700K to cool 6500K after installation, ensuring the light perfectly complements the siding, stone, or paint color.

Material Matching

In architectural lighting, the goal is to enhance the material, not just light it up.

My guide for your sourcing:

- 3000K (Warm White)7: Best for natural materials. wood soffits, red brick, and warm-toned stucco. It brings out the grain and texture.

- 4000K (Natural White): The "Sweet spot" for modern architecture. Ideal for white siding, grey concrete, and neutral colors.

- Tunable White (CCT)8: If you are unsure, or if the client is picky, buy the CCT version. We stock models that allow this flexibility. It combines warm and cool chips on one board.

Installation Note: CCT strips require 3 wires (V+, Warm, Cool) and a controller. While slightly more complex to wire than static white, it saves you from the disaster of the client saying "I don’t like the color" after you’ve already glued everything to the roof.

| Building Material | Recommended Color | Effect |

|---|---|---|

| Red Brick / Wood | 2700K – 3000K | Warm, cozy, highlights texture |

| White Stucco / Vinyl | 4000K | Clean, crisp, modern |

| Steel / Concrete | 5000K – 6000K | Sharp, industrial |

Conclusion

Roofline lighting defines the nighttime identity of a building. By sourcing IP67 Hollow Extrusion for lightweight protection, utilizing COB technology for perfect lines, and selecting the correct 24V/48V system for the scale of the roof, you deliver a premium architectural accent. Don’t let your building disappear in the dark.

-

Learn how effective heat dissipation can enhance the longevity and performance of lighting systems in elevated settings. ↩

-

Explore the advantages of IP67 Hollow Extrusion for lighting, ensuring durability and lightweight handling for high installations. ↩

-

Explore this link to understand how COB technology enhances LED lighting, making it more durable and visually appealing. ↩

-

Check this resource for essential installation tips on bending radius to ensure the longevity and performance of COB LED strips. ↩

-

Understanding power consumption helps in selecting the right power supply and ensuring efficient energy use. ↩

-

Exploring IP67 standards will help you choose the right lighting for outdoor applications, ensuring durability and safety. ↩

-

Discover why 3000K lighting is perfect for showcasing natural materials like wood and brick. ↩

-

Explore this link to understand how Tunable White (CCT) can enhance your lighting design flexibility. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

Event and Wedding LED Rope Lighting: Are Your Lights Ruining the “Big Day”?

Picture the scene: A bride spent thousands on her floral arrangements. The photographer is lined up for the perfect shot.…

Retail Display LED Rope Lighting: Is Your Lighting Scaring Away Customers?

We have all had that experience: walking into a retail store where the lighting feels harsh, clinical, or uneven. The…

Restaurant and Bar LED Rope Lighting Design Ideas: Is Your Ambience Killing Your Profits?

It is the oldest rule in the hospitality playbook: people don’t just pay for the food; they pay for the…