Silicone vs PVC vs Epoxy: Which Coating is Best for Outdoor LED Strips?

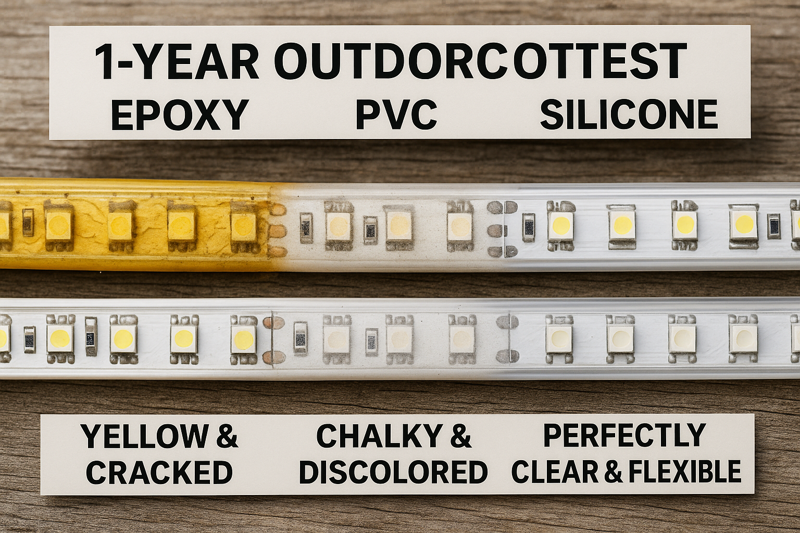

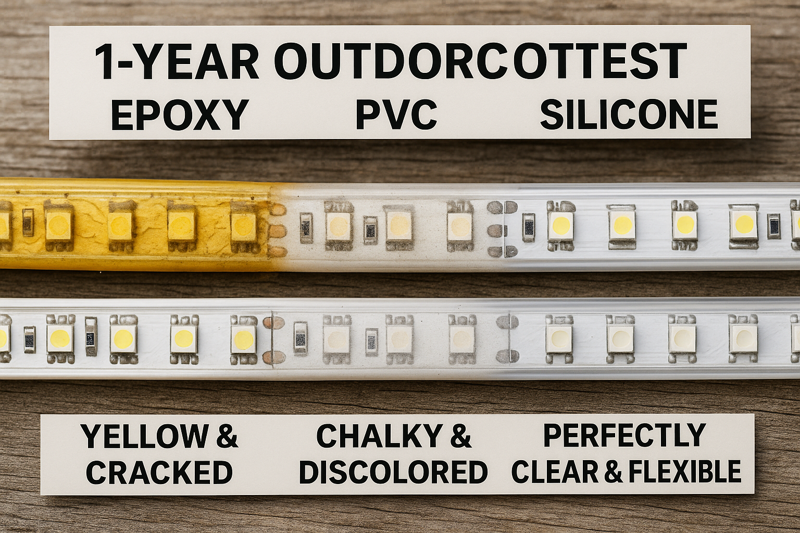

You’re sourcing for an outdoor project, and you’re faced with a choice. You see LED strips with Epoxy, PVC, and Silicone coatings, all claiming to be "waterproof," but at vastly different prices. Making the wrong choice means an installation that yellows, cracks, and fails in less than a year.

Silicone is the only professional choice for outdoor LED strips due to its superior UV, temperature, and chemical stability. Epoxy is a cheap alternative that quickly yellows and cracks. PVC offers physical toughness but fails in cold weather and has poor UV resistance.

As a manufacturer, the choice of protective material is one of the most critical decisions we make. It defines the product’s quality, lifespan, and reliability. I have seen firsthand how an inferior material can lead to catastrophic field failures, destroying not just the product, but also the installer’s reputation. This isn’t just a technical comparison. This is an insider’s guide to understanding the materials that will either make your project a lasting success or a costly failure. Let’s dissect each one.

Why is Cheap Epoxy Coating a Professional’s Worst Nightmare?

You’ve found an IP65 epoxy-coated LED strip that’s 30% cheaper than the silicone version. It seems like an easy way to increase your profit margin on a project. But you have a nagging feeling: what’s the catch?

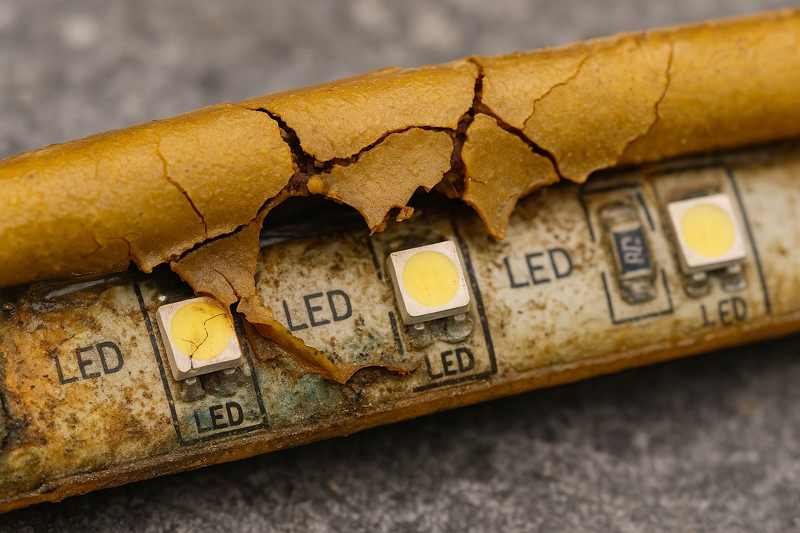

The catch is that epoxy is not designed for outdoor use. It’s a brittle, non-UV-stable plastic that will yellow, cloud over, and crack when exposed to sunlight and normal temperature fluctuations. It’s a guaranteed failure that turns short-term savings into long-term losses.

This is the classic "false economy" in our industry. Factories use epoxy for one reason: it’s incredibly cheap and easy to apply. They can take a standard indoor LED strip and simply pour a liquid epoxy resin over the top to achieve an IP65 rating. It looks great in the box. But as soon as you install it outside, a countdown timer starts. I’ve seen it hundreds of times. In climates with strong sun, the yellowing is visible in just a few months. After one year, it’s a brittle, ugly mess. For any professional who stands behind their work, using an epoxy-coated strip is not a risk; it’s a certainty of failure.

A Deeper Dive into Why Epoxy Fails

The failure of epoxy is not a possibility; it is a chemical inevitability. Let’s break down the process of its destruction.

-

Material Science 101: What is Epoxy?

Epoxy is a thermosetting polymer. This means it’s created by mixing two parts (a resin and a hardener) that cause a chemical reaction, curing it a solid, rigid state. While this creates a hard, glossy finish that looks good initially, this very rigidity and its chemical makeup are its downfall in an outdoor environment. It has no flexibility and its polymer bonds are highly susceptible to being broken down by environmental factors.

-

The Four Horsemen of Epoxy Failure:

- UV Degradation (Yellowing)1: The polymer bonds in epoxy resin are easily broken by the high energy of ultraviolet radiation from the sun. This process, called photodegradation, alters the material’s structure, causing it to turn a sickly yellow or brown. This not only looks terrible but it also drastically reduces the light output and shifts the color temperature of your LEDs.

- Thermal Embrittlement2: Epoxy doesn’t handle temperature changes well. As it ages and is damaged by UV, it loses any minor flexibility it had and becomes incredibly brittle, like old, sun-baked plastic.

- Stress Cracking3: This is the fatal blow. The epoxy coating and the flexible PCB of the LED strip expand and contract at different rates with temperature changes. Since the epoxy is now rigid, it cannot flex with the strip. This creates immense internal stress, which is relieved by the formation of micro-cracks all over the surface.

- Water Ingress4: The cracks completely compromise the "waterproof" rating. Water from rain and humidity now has a direct path to the electronics. It gets trapped under the epoxy, corrodes the solder joints, and the strip flickers and dies.

The entire value proposition of epoxy is based on a low initial price. But when you factor in the cost of labor, equipment rental, and new materials for the inevitable replacement job, it becomes the most expensive option by far.

Is a Tough PVC Jacket Good Enough for Outdoor LED Strips?

You’ve seen heavy-duty rope lights and industrial cables use PVC jackets. They feel tough and durable, so it seems like a reasonable choice for an outdoor LED strip light. Is this the durable middle-ground you’ve been looking for?

While PVC is physically tough and abrasion-resistant, it is a poor choice for high-quality architectural lighting. It offers limited UV stability without heavy additives and, most critically, becomes extremely brittle and can crack in freezing temperatures.

PVC (Polyvinyl Chloride) has its place. It’s excellent for applications where high physical toughness and low cost are the primary concerns. You see it on power tool cords and construction site lighting. However, it has significant drawbacks when it comes to the specific demands of permanent, high-end outdoor architectural lighting. Its biggest failure point is its performance in the cold. I have heard many stories from contractors in the northern US, Canada, and Europe who have seen PVC-jacketed products literally snap and crack during a harsh winter. This alone makes it too risky for any project where reliability across all four seasons is a requirement.

A Deeper Dive into the Limitations of PVC

Let’s analyze the technical trade-offs you make when choosing PVC. While it solves the "brittle when new5" problem of epoxy, it introduces its own set of critical flaws.

-

The Cold-Weather Catastrophe6

This is PVC’s most significant weakness. Standard PVC has a very high glass transition temperature. This means it doesn’t have to get that far below freezing before it changes from a pliable plastic to a rigid, brittle material. At -20°C (-4°F), it can become extremely fragile. If the strip is bent, vibrated, or impacted (even by something as simple as being brushed against), it can easily crack. This immediately destroys the waterproof seal and guarantees a future failure. While special flexible PVC formulations exist, they are more expensive and still do not match the low-temperature performance of silicone.

-

UV Instability and Discoloration7

Standard PVC is not UV stable. When exposed to sunlight, the UV radiation breaks down the material in a process called "chalking." The plasticizers that keep it flexible leach out of the surface, and it develops a dusty, white, chalky layer. It becomes discolored and loses its aesthetic appeal. Manufacturers can add UV-stabilizing additives to the PVC mixture, but this increases the cost and only delays the inevitable. The protection is not inherent to the material, and it will eventually degrade, unlike silicone.

-

Poor Thermal Conductivity8

LEDs need to stay cool to have a long life. PVC is an excellent thermal insulator. This is the opposite of what you want. A PVC jacket traps the heat generated by the LEDs, causing the chips to run hotter. As we know, higher operating temperatures lead to faster lumen depreciation (dimming), color shift, and a significantly shorter overall lifespan for the product.

PVC is a tempting material because it feels "tough." But for a permanent architectural installation that needs to look good and perform flawlessly for years in all climates, its weaknesses in cold weather and UV exposure, combined with its poor thermal properties, make it an unsuitable choice.

Why is Silicone the Only Professional Choice for Outdoor Lighting?

You’re a professional who guarantees your work. You need a "set it and forget it" solution that will look and perform as well in five years as it does on day one, regardless of whether it’s in the Arizona desert or the Chicago winter.

Silicone is the superior material because it is inherently stable. It is naturally immune to UV radiation, remains flexible down to -50°C and below, is stable in high heat, and is an excellent thermal conductor. It is the material you use when you want zero callbacks.

At my factory, when we engineer a product for a premium outdoor application, the material discussion is very short. We use high-grade, outdoor-rated silicone. Period. The reason is simple: it eliminates all the failure modes of cheaper materials. It does not yellow or crack under the sun. It does not become brittle and snap in the cold. It helps keep the LEDs cool. The slightly higher initial cost is insignificant when compared to the peace of mind and long-term reliability it buys. Choosing silicone is choosing to do the job right the first time.

A Deeper Dive into the Superiority of Silicone

Silicone is not just a better plastic; it’s a fundamentally different class of material (a polysiloxane) with a unique molecular structure that makes it perfectly suited for extreme environments.

-

The Power of the Silicon-Oxygen Backbone

Unlike plastics like Epoxy and PVC, which have carbon-based polymer backbones, silicone’s backbone is made of repeating, incredibly strong silicon-oxygen (Si-O) bonds. The energy from solar UV radiation is not powerful enough to break these bonds. This is why silicone is inherently UV stable. It doesn’t need additives or coatings. It simply does not react to sunlight. It will not yellow, chalk, cloud, or degrade. A silicone strip will remain optically clear and aesthetically perfect for its entire operational life.

-

Unmatched Temperature Performance

Silicone has one of the widest operating temperature ranges of any commercial polymer.

- Cold Flexibility: It remains highly flexible and resilient at temperatures down to -50°C (-58°F) and even lower. It will not become brittle or crack, ensuring the waterproof seal remains intact during the harshest winters. It laughs at the cold that destroys PVC and Epoxy.

- High-Heat Stability: It is also stable at very high temperatures, easily handling the heat on a sun-baked surface where other materials would soften or deform.

- Thermal Conductivity: Critically, silicone is a much better thermal conductor than other plastics. It acts as a "heat sink" of sorts, helping to pull heat away from the LED chips and transfer it to the mounting channel or the air, keeping the LEDs running cooler for longer life and better performance.

This combination of inherent UV stability and an incredibly wide, stable temperature range is what makes silicone the ultimate material for any outdoor electronic enclosure.

| Feature | Epoxy Coating | PVC Jacket | Silicone Extrusion |

|---|---|---|---|

| UV Resistance | Poor (Yellows & Cracks) | Poor to Fair (Chalks & Fades) | Excellent (Inherently Immune) |

| Cold Performance | Poor (Becomes Brittle) | Poor (Cracks Below Freezing) | Excellent (Remains Flexible) |

| Heat Dissipation | Fair | Poor (Insulates LEDs) | Good (Conducts Heat Away) |

| Expected Lifespan | 1-2 Years | 2-4 Years (Fails in cold/sun) | 5-10+ Years |

| Professional Verdict | Avoid at all costs. | Not suitable for pro lighting. | The only acceptable standard. |

Conclusion

The material housing your outdoor LED strip is not a minor detail; it is the single most important factor in its longevity. For professional results, the choice is clear: specify high-quality, silicone-extruded LED strips for a truly weatherproof, long-lasting installation.

-

Understanding UV degradation can help you choose better materials and protect your projects from premature failure. ↩

-

Learn about thermal embrittlement to ensure your epoxy applications withstand temperature changes effectively. ↩

-

Discover ways to prevent stress cracking to enhance the durability and longevity of your epoxy projects. ↩

-

Explore the impact of water ingress on epoxy to make informed decisions for waterproofing your applications. ↩

-

Discover the factors that contribute to brittleness in materials, aiding in better material selection. ↩

-

Understanding how cold affects PVC can help you make informed choices for your projects. ↩

-

Explore the impact of UV on PVC to ensure longevity and aesthetic appeal in your applications. ↩

-

Learn about thermal conductivity’s role in LED performance to enhance your lighting solutions. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…