Understanding LED Rope Light Specifications: Are Your Specs Setting You Up for Failure?

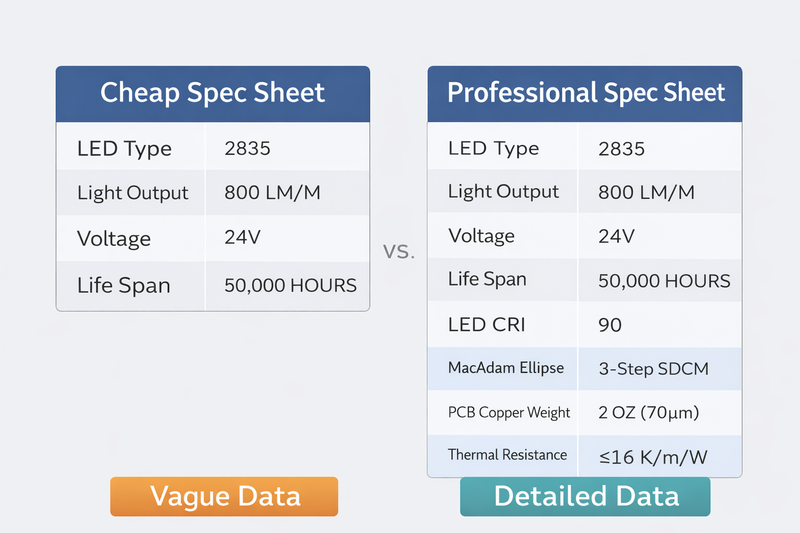

You are looking at two spec sheets from two different suppliers. Both claim "Waterproof," both say "High Brightness," and both look identical in the photos. Yet, one costs $2 a meter and the other is $6. If you choose wrong, you either burn your budget or burn your reputation when the lights fail six months later.

To truly understand LED rope light specifications, you must look beyond the basic voltage and color temperature. You need to analyze the specific manufacturing details: the LED density (chips per meter) for dot-free illumination, the Copper Weight (2oz vs 3oz) for voltage stability, the CRI rating (Ra90+) for color accuracy, and the extrusion method (Solid vs. Hollow) for true waterproofing.

As a factory owner who has spent years negotiating with material suppliers and tweaking production lines, I know exactly where factories cut corners to lower the price. They count on you not understanding the "fine print" of the specifications. Today, I am going to decode the technical jargon so you can buy with the confidence of an engineer, not just a procurement manager.

Why Does "LED Density" Matter More Than Lumen Output?

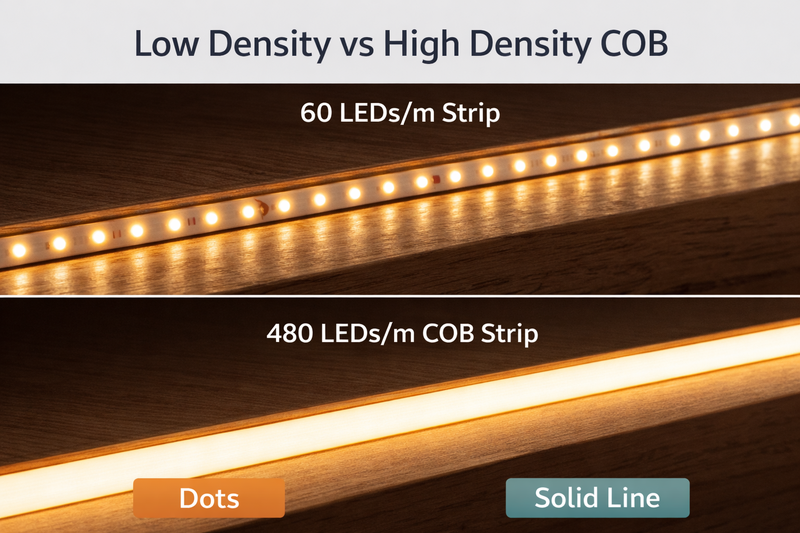

Most buyers look straight at the "Lumens" number. High lumens are good, right? Not always. If you have high lumens but low density, you get a "spotted" effect that looks cheap and causes glare.

Density refers to the number of LED chips packed into one meter of strip. For a professional, seamless "neon" look without visible dots, you should look for Chip-on-Board (COB) specifications ranging from 320 to 512 LEDs per meter. This high density eliminates the need for deep diffuser channels and creates a uniform, linear light source.

The Math of Smooth Lighting

In the old days of SMD (Surface Mounted Device) lighting, 60 or 120 LEDs per meter was standard.

- The Spotting Issue: With 60 LEDs/m, the distance between chips is roughly 16mm. Unless you put this inside a deep aluminum profile with a thick milky cover, you will see individual dots.

- The COB Advantage:

- According to our manufacturing standards, COB (Chip on Board)1 technology allows us to mount chips directly to the PCB and cover them with a continuous phosphor layer.

- Our specs typically list 320, 384, 480, or even 512 LEDs per meter2.

- At 480 LEDs/m, the chips are spaced only millimeters apart. The phosphor bridges that tiny gap.

Why is this a critical spec?

If your client is installing these lights under a glossy marble countertop or a reflective glass display case, "dots" are a disaster. They reflect back as a string of pearls, ruining the clean lines of the architecture. High density (320+ LEDs/m) ensures that even on the most reflective surfaces, the light appears as a single, solid bar.

Efficiency Note:

High density doesn’t always mean "blindingly bright." It means uniform. By spreading the light source across hundreds of tiny chips rather than a few big ones, we reduce glare and improve thermal management, as the heat isn’t concentrated in hot spots.

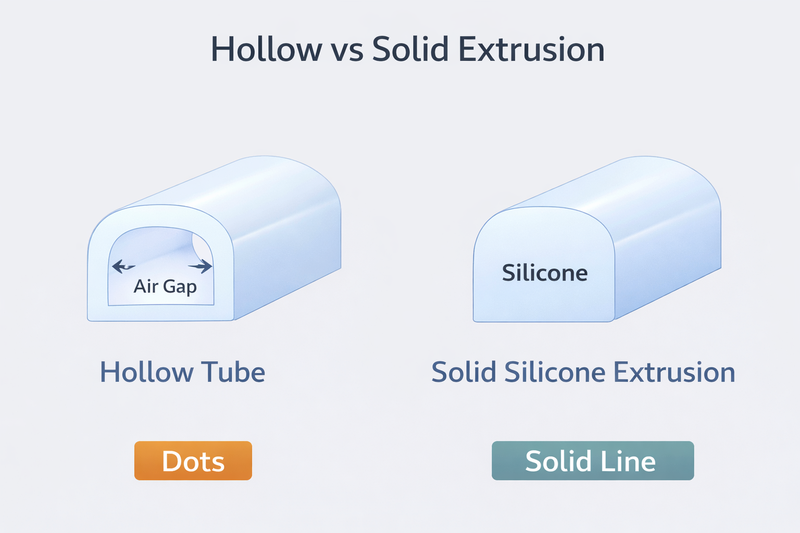

What Is the difference Between IP67 and IP68 (And Why Does "Extrusion" Matter)?

"Waterproof" is the most abused term in the LED industry. I have seen clients buy "IP67" lights that filled with water after one rainstorm. The rating number (IP67 vs IP68) is important, but the manufacturing method used to achieve it is even more critical.

You must distinguish between "Hollow Extrusion" (often labelled IP67) and "Solid Extrusion" (IP68). Hollow tubes leave air gaps that attract condensation due to thermal expansion, causing failure. Solid Extrusion completely encapsulates the electronics in silicone, eliminating air voids and ensuring true long-term submersible performance.

Decoding the IP Ratings

When you read a specification sheet, do not just look for "IP68." Look for the words "Solid Extrusion3" or "Potting4."

The "Hollow" Trap (IP67):

- Many suppliers sell a silicone tube with an LED strip slid inside. They seal the ends with glue.

- The Spec: This is often listed as IP67.

- The Reality: There is air inside that tube. When the LEDs heat up, the air expands. When they cool down (or are hit by cold rain), the air contracts. This creates a vacuum effect that sucks moisture in through the end caps. Once water is inside, it has nowhere to go. It boils with the heat of the LEDs and corrodes the PCB.

The "Solid" Standard (IP68):

- The Spec: Our IP68 COB strips use Solid Extrusion technology.

- The Process: We co-extrude the silicone over the LED tape while it is still liquid. The silicone seeps under the chips and over the resistors.

- The Result: There is zero air space. No air = No condensation.

- Durability: This method also makes the strip crush-proof. You can physically step on an IP68 solid extrusion strip, and it will likely survive because the silicone acts as a shock absorber. This is vital for floor installations or high-traffic event walkways.

| Rating | Method | Risk Factor | Best Application |

|---|---|---|---|

| IP20 | Bare Board | High (No protection) | Indoor, dry cove lighting |

| IP65 | Thin Spray/Coating | Medium (Scratches easily) | Indoor kitchens, humid areas |

| IP67 | Hollow Tube | High (Condensation risk) | Temporary outdoor (Christmas lights) |

| IP68 | Solid Extrusion | Zero (Fully filled) | Swimming pools, Facades, Ground |

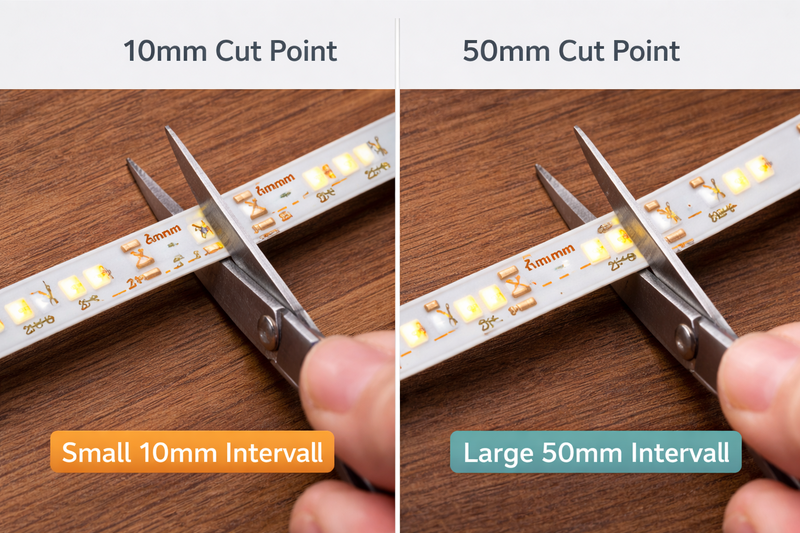

Why Should You Care About "Cutting Length"?

Have you ever tried to install LED lights into a custom sign or a specific cabinet size, only to find you have to cut off 4 inches of usable light because the "cut points" are too far apart? It leaves dark corners and looks unprofessional.

The "Cutting Unit" or "Scissor Blade" interval on a spec sheet dictates the precision of your installation. While standard strips cut every 50mm or 100mm, high-end COB strips offer cutting lengths as short as 10mm or 12.5mm, allowing for surgical precision in custom joinery and signage.

Precision in Design

If you are a contractor lighting a simple room perimeter, cutting length doesn’t matter much. But if you are an OEM manufacturer making neon signs or a millworker lighting a specific shelf, it changes everything.

The Mathematics of Cut Points:

- Standard 12V: Usually cuts every 25mm.

- Standard 24V: Usually cuts every 50mm.

- The Issue: Imagine you have a shelf that is exactly 480mm wide. If your cut point is 50mm, you can cut at 450mm (leaving a 30mm dark gap) or try to squeeze in 500mm (which won’t fit).

The Precision Spec:

- Our specialized COB specifications offer much tighter tolerances.

- For 12V COB5, we have cutting lengths6 of 10mm.

- For 5V RGB+IC, we have cutting lengths of 12.5mm .

- Why it matters: With a 10mm cut point, on that 480mm shelf, you can cut the light at exactly 480mm (or 470mm to allow for end caps). The light fills the entire void. There are no dark spots at the edges.

Voltage Influence:

Notice that higher voltage usually means longer cut lengths:

- 12V = 10mm or 25mm cuts.

- 24V = 50mm cuts.

- Insight: If your project demands high precision (like small signage letters), 12V or 5V is often the superior specification choice over 24V, purely based on cutting geometry.

Does "Board Width" Affect Your Installation Options?

Most people assume all LED strips are the same size—roughly 10mm wide. But in modern architectural design, "slim" is in. If you buy a standard width strip for a delicate application, you might find it doesn’t fit in the routed channel.

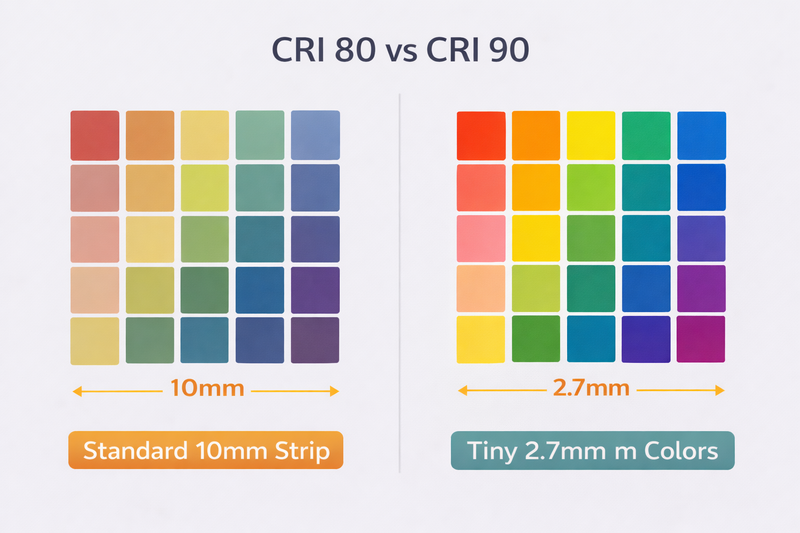

Specification sheets list "Board Width" or "PCB Width." While 8mm and 10mm are standard, specialized "Nano" strips are now available in 4mm and even 2.7mm widths. These micro-specs enable lighting integration into ultra-thin shelf edges and intricate furniture details where standard strips simply won’t fit.

The Trend Toward Invisibility

The goal of modern lighting is to see the light, not the fixture.

Standard Widths:

- 8mm – 10mm: This is the industry workhorse. It fits in standard aluminum profiles. It has good heat dissipation because there is more copper surface area.

- 12mm: Used for high-power or RGBW multi-color strips.

The "Nano" Specs:

- 4mm Width: We manufacture a specific COB series on a 4mm PCB. This is perfect for narrow saw kerfs in cabinetry.

- 2.7mm Width7: This is the extreme end of the specification capable of being produced. It is incredibly thin.

- Application: You can route a tiny groove in the edge of a 3/4" plywood shelf or even embedding light into glass display hardware.

- Trade-off: The physical bending of a 2.7mm strip is more delicate than an 8mm strip. The spec sheet will warn you: "Please do not fold it in half, Please do not bend it horizontally". You must treat these ultra-thin specs with care during installation.

Heat Management8:

A narrower board equals less surface area to dissipate heat. If you choose a 2.7mm or 4mm spec, ensure you aren’t over-driving it with high wattage (keep it under 10W/m usually) or ensure it is mounted to a metallic surface to act as a heat sink.

What Do "CRI" and "SDCM" Actually Tell You About Quality?

Have you ever replaced a section of LED tape and realized the new white light looks "pinkish" compared to the old "yellowish" white, even though both are labelled "3000K"? That is a specification failure in sorting and color rendering.

To ensure professional color consistency, you must look for "Ra90" (CRI>90) and "SDCM < 3" (Standard Deviation of Color Matching). Ra90 guarantees true color representation of products and skin tones, while SDCM < 3 ensures that every batch of lights you buy matches perfectly without visible tint variations.

The Color Quality Metrics

Specs like "Warm White" are subjective. Specs like "Ra90" and "CRI" are scientific.

CRI (Color Rendering Index):

- The Baseline: Market standard is Ra80. This is "fine" for hallways or garages.

- The Premium Spec: Our COB strips are rated Ra90.

- Why pay for it? If you light a grocery store with Ra80, the meat looks brown and apples look dull. With Ra90, the R9 (red) spectrum is boosted. Apples look crisp red; meat looks fresh. In a high-end customized home, Ra90 makes wood floors and furniture look rich and expensive.

CCT (Correlated Color Temperature):

- We offer the full range: 2000K (Candlelight), 2700K (Incandescent), 3000K (Halogen), 4000K (Natural), 6500K (Cool) .

- The Trap: Cheap factories have loose tolerances. Their "3000K" might actually vary from 2800K to 3200K between rolls.

- The Fix: Look for SDCM (Standard Deviation of Color Matching) or "MacAdam Ellipse" steps. A specification of SDCM < 3 means the human eye cannot see the difference between any two chips on the strip.

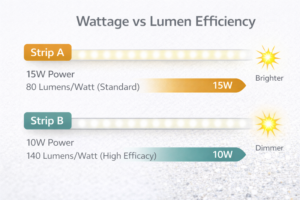

Lumen Efficiency:

- Check the "Light Efficiency" column.

- Standard strips: ~80-90 lm/W.

- High Efficiency strips: 100-130 lm/W.

- Benefit: A strip with 130 lm/W produces the same brightness as a standard strip but uses 30% less electricity. For large commercial projects running 24/7, this spec saves the client money on energy bills and allows for smaller power supplies.

Conclusion

Reading an LED rope light specification sheet is like reading a nutrition label; the truth is in the numbers, not the marketing claims. By demanding High Density (320+ LEDs/m) for uniformity, Solid Extrusion (IP68) for true weatherproofing, and precise Cutting Units (10mm-12.5mm) for custom fit, you ensure your project succeeds. Don’t let a cheap spec sheet fool you—quality is quantifiable.

-

Explore the advantages of COB technology for better lighting solutions and improved efficiency. ↩

-

Learn how LED density impacts lighting quality and uniformity for various applications. ↩

-

Understanding Solid Extrusion technology can help you choose more durable and reliable LED lighting solutions. ↩

-

Exploring potting in electronics will reveal how it enhances protection and longevity for various devices. ↩

-

Exploring 12V COB technology can provide insights into achieving high precision in lighting applications, crucial for professional results. ↩

-

Understanding cutting lengths can enhance your lighting design, ensuring no dark spots and perfect fit for your projects. ↩

-

Explore this link to understand the unique applications and care needed for ultra-thin LED strips, ensuring optimal performance. ↩

-

Discover effective heat management strategies for LED lighting to enhance longevity and performance in your projects. ↩

Interested in Our LED Solutions?

Get professional consultation and customized LED lighting solutions for your projects. Contact our expert team today.

Related Articles

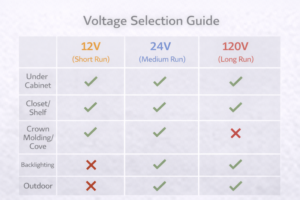

12V vs 24V vs 120V LED Rope Lights: Which to Choose? (Don’t Burn Your House Down)

You have planned the perfect lighting layout. The channels are cut, the wires are pulled, and the client is expecting…

IP Ratings for LED Rope Lights: Indoor vs Outdoor Use (Are You Drowning Your Investment?)

It is 2:00 AM. A thunderstorm is hammering the facade of the luxury hotel you just finished renovating. Your phone…

LED Rope Light Brightness: Lumens and Visibility Guide (Are You Buying Too Dim or Too Bright?)

Picture this: You are standing in the middle of a freshly finished high-end retail store. The design is sleek, the…