What Are the Different Types of LED Strip Lights?

You’re trying to choose a strip light, but you’re facing a wall of confusing numbers and acronyms. 5050, 2835, RGBIC, 24V—making the wrong choice could mean a failed project for your client.

The main types are defined by their SMD chip size (e.g., 2835, 5050), their color capabilities (single color, RGB, RGBW, RGBIC), and their operating voltage (12V or 24V). Each combination is engineered for a specific application, from simple accent lighting to complex, dynamic effects.

As a manufacturer, I deal with these specifications every day. These aren’t just arbitrary model numbers; they are the language that describes what a strip light can do. Understanding this language is the key to moving from a generic installer to a true lighting designer who can select the perfect product for any job with confidence.

What Does 2835 LED Mean?

You see numbers like 2835 or 5050 on every product page. They seem technical and confusing, like you need an engineering degree to understand them.

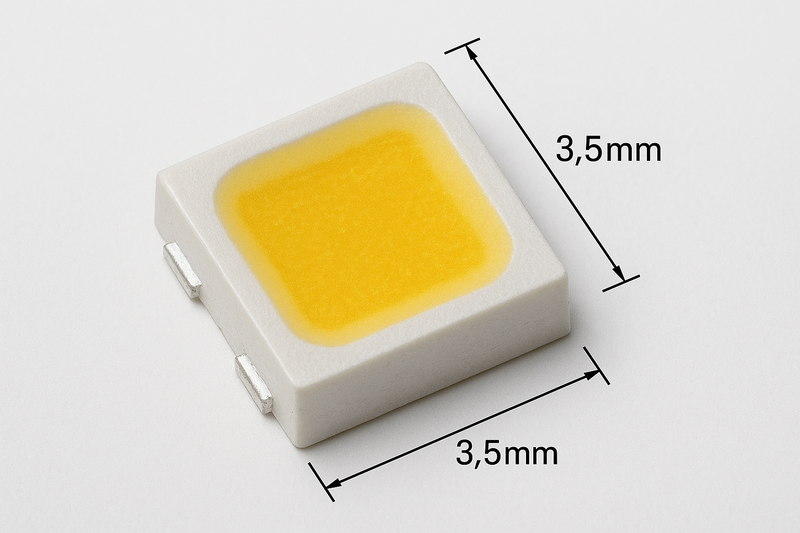

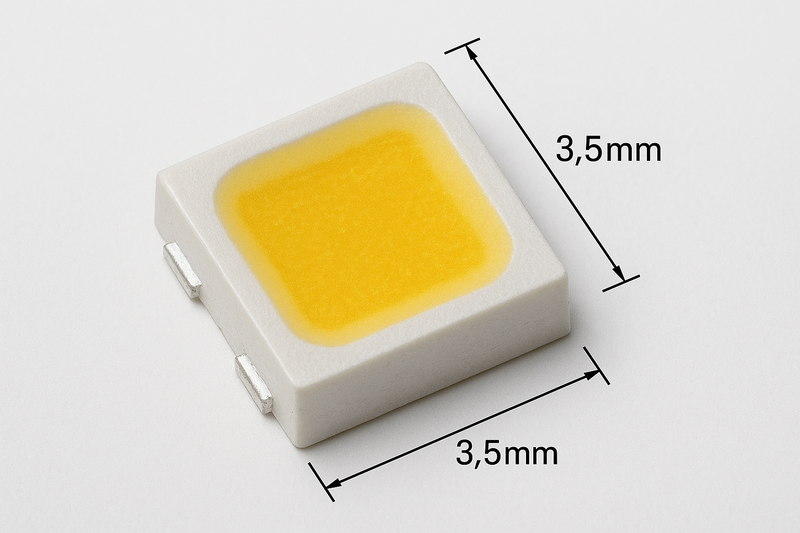

It’s simply the dimensions of the LED chip on the strip. A 2835 chip is 2.8 millimeters by 3.5 millimeters. This number isn’t a model; it’s a measurement. It gives you an idea of the chip’s size and potential brightness.

This is the first piece of the puzzle, and it’s the easiest to solve. For years, the industry has used this naming convention to classify the Surface Mount Device (SMD) chips used on flexible strips. Once you know this, you can immediately tell a lot about a strip. Larger numbers generally mean larger chips, which can often produce more light.

Decoding the Chip Number

Understanding the chip size1 is fundamental to specifying the right product. It’s the engine of the strip light.

- The Naming Convention: The four-digit number is just two, two-digit measurements put together. A 5050 chip is 5.0mm x 5.0mm. An older, less common 3528 chip was 3.5mm x 2.8mm.

- Why It Matters: Chip size correlates with a few key factors. A larger surface area allows for a larger light-emitting diode (or multiple diodes), which generally means more light output (lumens). It also affects how well the chip can dissipate heat, which is crucial for its lifespan and efficiency. For example, the 2835 chip2 was a major improvement over the old 3528 because its rectangular design included a better internal heat sink, making it more efficient and reliable.

| Chip Name | Dimensions | Common Application |

|---|---|---|

| 2835 | 2.8mm x 3.5mm | High-efficiency white and single-color light. |

| 5050 | 5.0mm x 5.0mm | Powerful RGB and RGBW color-changing light. |

| 3528 | 3.5mm x 2.8mm | Older, lower-power single-color light. |

Which Is Better, 5050 or 2835 LED Lights?

You have two common options for a project. One is not necessarily more expensive than the other, so which one should you choose to get the best result?

Neither is universally "better"; they excel at different jobs. For high-quality, efficient white or single-color light, the 2835 chip is the superior, modern choice. For bright, powerful, color-changing RGB effects, the larger 5050 chip is the standard.

Thinking in terms of "better" is a trap. It’s about choosing the right tool. You wouldn’t use a hammer to drive a screw. In the same way, using a 5050 strip for a high-end architectural under-cabinet lighting job is the wrong choice, because the 2835 chip will give you a brighter, more efficient, and cleaner white light for that application.

Choosing the Right Tool for the Job

The internal structure of these chips is what makes them suited for different tasks.

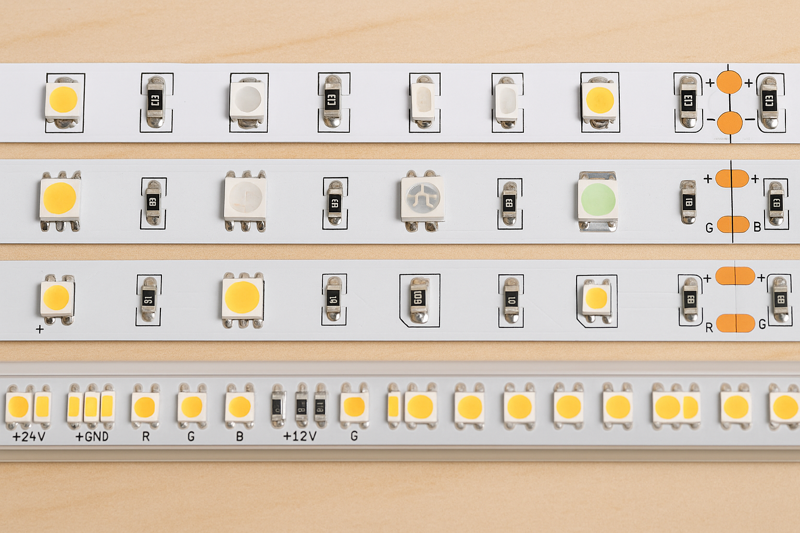

- The Workhorse: 2835 SMD: This chip is designed for one thing: producing single-color light with maximum efficiency and great heat dissipation. It contains one powerful diode. This makes it the go-to for all professional architectural lighting where the quality of white light is critical (e.g., CRI 90+). It produces more lumens per watt than a 5050 chip when used for white light.

- The Color Changer: 5050 SMD: The magic of the 5050 is that it isn’t one big diode; it’s a package containing three smaller diodes (one red, one green, and one blue). By controlling the brightness of these three internal diodes, you can mix them to create millions of different colors. This tri-chip design makes it perfect for RGB lighting, but less efficient for producing pure white light.

| Factor | 2835 SMD3 Chip | 5050 SMD4 Chip |

|---|---|---|

| Best Use Case | High-quality white & single color | Color-changing (RGB/RGBW) |

| Efficiency (White Light) | Higher | Lower |

| Internal Structure | One powerful, single-color diode | Three smaller diodes (R, G, B) |

Is RGB or RGBW Better?

A designer wants colored accent lighting but also needs a high-quality, functional white light from the same strip. You show them an RGB strip, but the "white" color looks bluish and strange.

RGBW is better because it adds a dedicated, fourth white LED chip to the standard red, green, and blue. This allows you to create a pure, high-quality white light that standard RGB strips can only approximate by mixing colors, which often looks pastel or blue-tinted.

This is one of the most important distinctions for high-end projects. Trying to create white light by blasting red, green, and blue at full power is like trying to paint a wall white by mixing all your other paint colors together. You get a muddy, unsatisfying result. For any application where the strip will be used for both ambient color and functional white light, RGBW is not just better; it’s a necessity.

The Fourth Channel Advantage

Adding that dedicated white channel solves a major problem.

- How RGB Makes "White": In an RGB system, the controller turns the red, green, and blue diodes on at 100% intensity. In theory, these three primary colors of light should combine to produce white. In reality, slight imperfections in the diodes result in a white that has a noticeable blue or cool pink tint. It’s also not as bright as a dedicated white chip5.

- How RGBW Solves It: An RGBW strip adds a fourth channel. It has the standard 5050 RGB chips, but in between them, it has a dedicated 2835 white chip (or a 5050 chip that contains a fourth white diode). When you want white, the controller simply turns off the R, G, and B diodes and turns on the pure white one. This gives you a true, high-quality white and also saves energy. You can even choose the color temperature of that white chip (e.g., 3000K Warm White, 4000K Neutral White).

| Feature | RGB | RGBW6 |

|---|---|---|

| White Light Quality | Poor (Bluish, low CRI) | Excellent (Pure, high CRI) |

| How White is Made | Mixing Red + Green + Blue | Using a dedicated white diode. |

| Best For | Purely decorative color effects | Projects needing both color and functional white light. |

Is RGB or RGBIC Better?

Your client wants dynamic, color-chasing effects for a game room or bar. You see RGB and a newer option called RGBIC. Will standard RGB do the job?

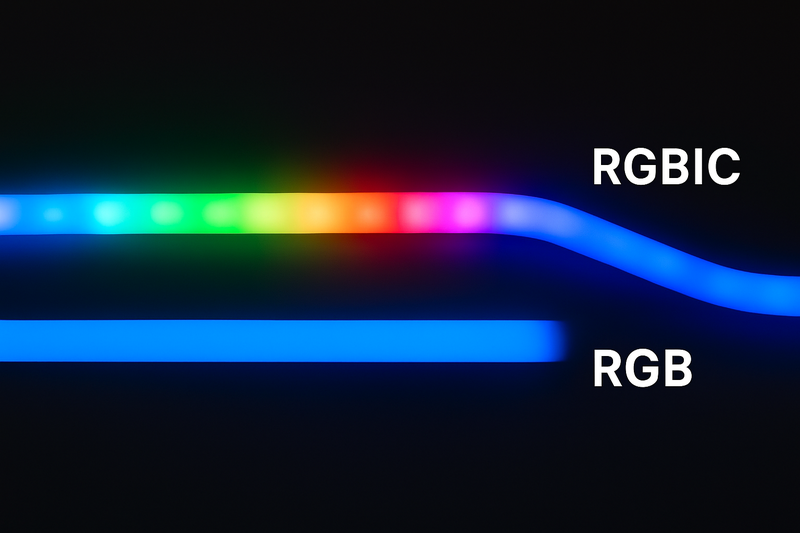

RGBIC is significantly better if you want dynamic, flowing, rainbow-like effects. "IC" stands for Independent Control, meaning each small section of the strip has its own chip. This allows you to display multiple colors at the same time, which standard RGB cannot do.

Standard RGB is like a string of old Christmas lights; when you choose a color, the entire strip turns that color. It’s an all-or-nothing system. RGBIC is a massive technological leap forward. The integrated circuit (IC) on the strip acts like a tiny computer for every few LEDs, allowing for incredibly complex and beautiful effects like chasing, flowing, and segmented color scenes.

The Power of Independent Control

The difference between these two technologies comes down to one tiny component.

- Standard RGB: The entire strip is one single circuit. The controller sends a signal (e.g., "turn red") and every single 5050 chip on the strip responds identically. It’s simple and effective for creating static color scenes or slow fades where the whole strip changes color together.

- RGBIC: An IC chip is added to the circuit board for every segment of LEDs (typically every 3 or 6 LEDs). The controller sends a much more complex signal down the data line, and each IC chip listens for its specific instruction. One chip might be told "turn blue," while the next one is told "turn purple," and so on. This creates the "magic" of seeing multiple colors moving along one continuous strip. It’s essential for any project that requires eye-catching, dynamic effects.

| Feature | Standard RGB7 | RGBIC8 (Addressable) |

|---|---|---|

| Color Control | The entire strip is one color at a time. | Each segment can be a different color. |

| Effects | Solid colors, fade, flash (all one color) | Chasing, rainbow, flowing, meteor effects. |

| "IC" Chip | No | Yes, one for each segment. |

Is a 12V or 24V LED Strip Better?

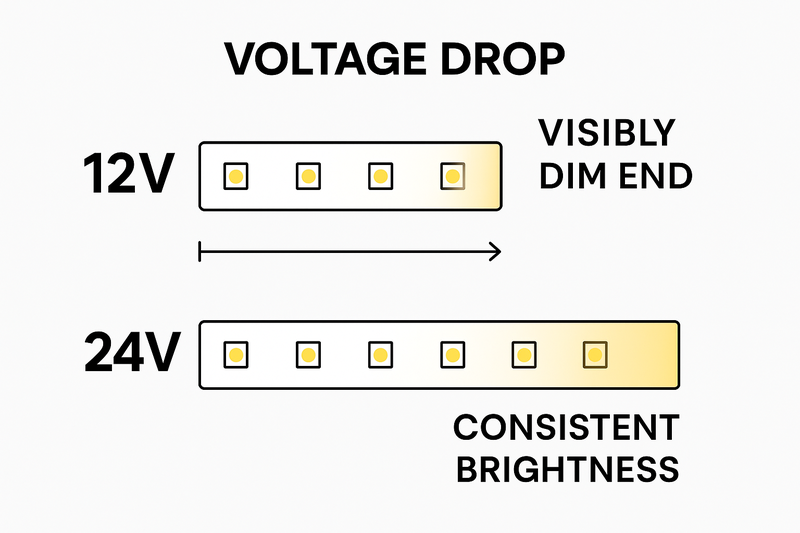

You are planning a long run of LED strip lights for a ceiling cove. You’re worried that the end of the strip will be noticeably dimmer than the beginning.

For any installation longer than 5 meters (16 feet), a 24V LED strip is significantly better. 24V systems can run twice as far as 12V strips before experiencing the effects of voltage drop, which causes the lights to dim at the far end of the run.

From an installer’s perspective, this is one of the most practical decisions you will make. Voltage drop is a law of physics, and fighting it with a 12V system on long runs requires more wiring, more power supplies, and more complexity. By starting with a 24V system, you simplify the installation, reduce the amount of wiring needed, and ensure a more professional and consistent result for the client.

The Efficiency of Higher Voltage

The reason 24V performs better is explained by Ohm’s Law.

- Current and Voltage Drop: For an LED strip of a given power (watts), a 24V system draws half the current (amps) of a 12V system. Voltage drop is directly related to the current—the lower the current, the less voltage is lost over the length of the copper conductor in the strip.

- Practical Impact: A 12V strip often shows noticeable dimming after just 5 meters. A 24V strip can typically run for 10 meters before you see the same level of dimming. This means fewer power connections are needed for large projects like cove lighting, toe-kicks, and architectural outlines.

- Component Health: The lower current in a 24V system also puts less thermal stress on the components of the strip and the wiring, which can contribute to a longer and more reliable lifespan. It’s a more robust and efficient system overall.

| Feature | 12V System | 24V System |

|---|---|---|

| Max Run Length | Shorter (approx. 5 meters) | Longer (approx. 10 meters) |

| Voltage Drop | Higher (dims faster) | Lower (maintains brightness) |

| Current (Amps) | Higher | Lower (more efficient) |

| Best For | Short accents, vehicle lighting | Long runs, architectural lighting. |

What Is the Strongest LED Strip Light?

Your project requires the maximum possible light output. How do you find a strip that is truly bright and not just a weak accent light?

The "strongest" or brightest LED strips combine three factors: a high-efficiency chip like the 2835, a high density of those chips (e.g., 120 or 240 LEDs per meter), and 24V power to maintain brightness over distance. The specification to look for is lumens per meter/foot.

Brightness is not about a single feature, but about a combination of specifications working together. A strip with big 5050 chips but only 30 of them per meter can be dimmer than a strip with smaller 2835 chips packed tightly at 120 per meter. As a buyer, you must look past simple chip names and focus on the final, measured output: lumens.

The Recipe for Brightness

For maximum light output, you need the right ingredients.

- 1. Chip Efficiency: Modern 2835 chips are extremely efficient and are the foundation of most high-output white light strips.

- 2. LED Density: This is critical. Doubling the number of LEDs per meter will nearly double the light output. High-density strips (120, 240, or even more LEDs/meter) are designed for primary illumination, not just accents. Some designs even use double or triple rows of chips.

- 3. Power (Watts per Meter): Brightness requires power. Look at the watts per meter (or foot). A strip that consumes 5W/m will be an accent light. A strip that consumes 15-20W/m is a serious light source.

- 4. COB Strips: A newer technology, Chip on Board (COB), places tiny diodes directly onto the flexible circuit board. This allows for extremely high densities (over 500 LEDs/meter), creating a completely uniform, dot-free line of intense light.

| Factor that increases strength | Low Strength Example | High Strength Example |

|---|---|---|

| LED Density | 30 LEDs per meter | 120 or 240 LEDs per meter |

| Power Consumption | 4.8 Watts per meter | 14.4 or 19.2 Watts per meter |

| Technology | Standard 30 LED/m | High-density SMD or COB strips |

Conclusion

Understanding chip type, color capability, and voltage empowers you. It allows you to select the perfect product for any job, ensuring a professional, durable, and impressive result every time.

-

Understanding chip size is crucial for selecting the right LED lights, impacting efficiency and light output. ↩

-

The 2835 chip offers improved efficiency and reliability, making it a popular choice for modern lighting solutions. ↩

-

Explore the benefits of 2835 SMD chips for efficient lighting solutions, especially in architectural settings. ↩

-

Learn about the innovative tri-chip design of 5050 SMD chips and their applications in RGB lighting. ↩

-

Learn about dedicated white chips and how they improve light quality and energy savings in lighting systems. ↩

-

Explore the advantages of RGBW lighting to understand how it enhances color quality and energy efficiency. ↩

-

Learn about Standard RGB technology and its applications for simple and effective lighting solutions. ↩

-

Explore the advantages of RGBIC technology for dynamic lighting effects and creative projects. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…