What Defines a Top 10 Waterproof LED Strip Light for 2025?

You need to select an outdoor LED strip for a critical project, but every option claims to be the best. Choosing the wrong one can lead to premature failure, angry clients, and costly replacements.

A top-tier waterproof LED strip is defined not by a brand name, but by a combination of key technical features: a UV-stable silicone body with an IP67 rating, a 24V system for long-run consistency, high-density LEDs for smooth light, and verified UL certification for safety.

From my factory’s perspective, I can tell you that a product’s true quality is revealed in these details. A "top 10" list shouldn’t be about who has the best marketing. It should be a checklist of the non-negotiable features that guarantee performance, longevity, and safety. Let’s break down what truly matters.

Why is a Silicone IP67 Body a Top Feature?

You installed a weatherproof strip, but after one season it’s yellowed, cracked, and full of moisture. The cheap plastic coating has completely failed, destroying the product and your reputation along with it.

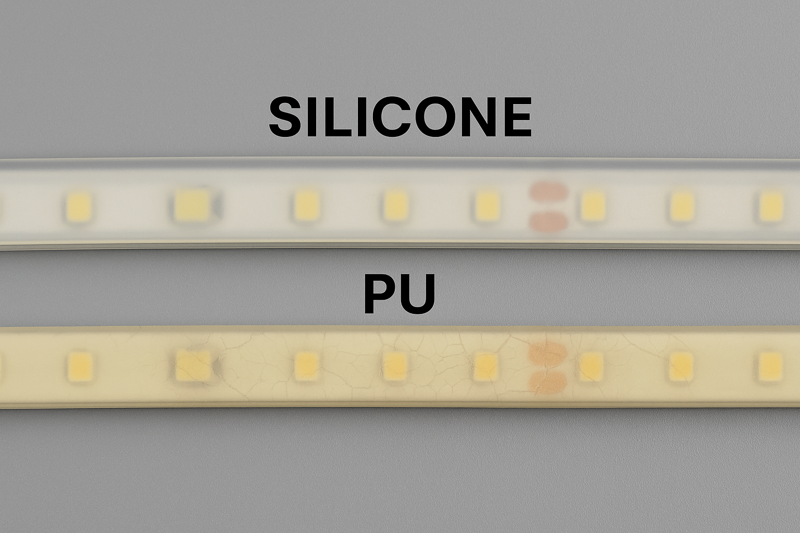

An IP67 rating in a silicone body is the feature for outdoor durability. The IP67 rating ensures it can survive submersion, while the silicone material prevents UV damage from the sun, which causes cheaper PU coatings to yellow and crack.

I see this failure mode constantly. A product’s IP rating is meaningless if the material creating the seal degrades in sunlight. This is a critical point I emphasize with clients like Tom; the material science is just as important as the electrical engineering. Investing in silicone is investing in a product that will last.

The Dual Threats of Water and Sun

A top-rated outdoor product must defeat both elements simultaneously.

IP67: The Gold Standard for Water Protection

The "7" in IP671 is a specific certification that the product can be fully submerged in up to 1 meter of water for 30 minutes without any leakage. This is a tough test that simulates real-world conditions like deep puddles on a patio or melting snow. A lower IP65 rating only protects against splashes and is not suitable for most ground-level outdoor applications where water can pool.

Silicone: The Only Choice for UV Resistance

The sun’s ultraviolet rays are destructive to most plastics.

- Silicone2 (Top Tier): It is an inorganic material, making it inherently immune to UV degradation. It will not yellow, harden, or crack over time. It remains flexible in both hot and cold temperatures, maintaining its waterproof seal.

- Polyurethane (PU) / Epoxy (Low Tier): These cheaper materials are organic plastics that are broken down by UV light. They quickly turn yellow, become brittle, and crack, completely compromising the IP rating.

| Feature | Low-Tier Strip (PU/Epoxy) | Top-Tier Strip (Silicone) |

|---|---|---|

| IP Rating | IP65 (Often Fails) | IP67 (Verified) |

| UV Resistance | Poor | Excellent |

| Longevity | 1-2 Years (at best) | 5+ Years |

| Appearance | Yellows and Cracks | Remains Clear and Flexible |

How Does a 24V System Place a Strip in the Top Tier?

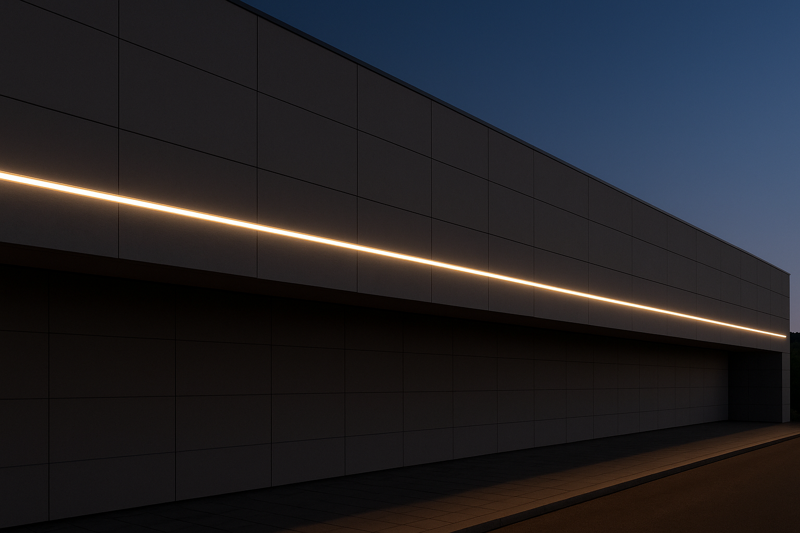

You’ve completed a long, 50-foot installation along a wall. You turn it on and the beginning is bright white, but the far end is noticeably dim and has a yellowish tint. The effect is unprofessional and unacceptable.

A 24V system is a top-tier feature because it virtually eliminates visible voltage drop on long runs. This ensures perfectly consistent brightness and color from the start of the strip to the end, a critical requirement for any professional architectural project.

This is one of the first technical questions I ask a client about their project. If the run is longer than 5 meters (16 feet), I tell them 24V is not an option, it’s a requirement. It is a fundamental difference between a DIY-grade product and a professional one designed for large-scale applications.

The Physics of Professional Lighting

Consistent power delivery is key to a flawless visual result.

Understanding Voltage Drop3

Voltage drop is the natural loss of electrical energy as it travels through a conductor. In a low-voltage 12V system, this loss is significant enough to cause dimming after just a few meters. The LEDs at the far end of the strip simply aren’t receiving the full 12 volts they need to operate at peak brightness and correct color temperature.

Why 24V is the Solution

For the same amount of power (watts), a 24V system4 uses half the current (amps) of a 12V system. According to Ohm’s Law, voltage drop is directly related to current. By cutting the current in half, you drastically reduce the voltage drop. This allows you to power runs up to 10 meters (32 feet) or more from a single end, with no perceptible difference in brightness or color along the entire length.

| System Voltage | Max Single-Ended Run Length | Brightness Consistency | Common Use Case |

|---|---|---|---|

| 12V | ~5 meters / 16 feet | Poor on long runs | Short accents, vehicles |

| 24V | ~10 meters / 32 feet | Excellent | Architectural, Landscape |

What Makes High-Density LEDs a Top-Rated Feature?

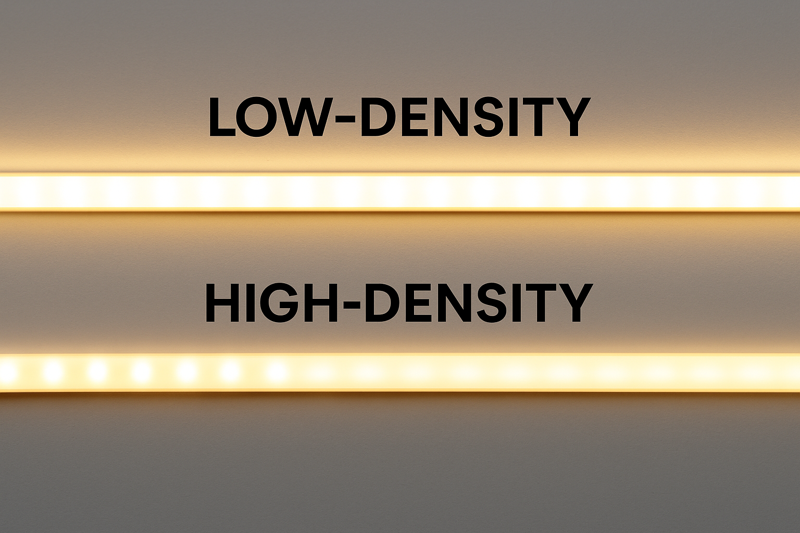

You wanted a smooth, seamless line of light under a countertop or railing, but instead, you can see every individual LED. The distracting "dotted" look makes your high-end installation look cheap and unfinished.

High-density LED strips, with at least 120 LEDs per meter, are a top feature because they eliminate spotting. By placing the light sources closer together, they create a smooth, continuous line of light that is essential for modern architectural design.

When architects and lighting designers specify our products, this is a major point of discussion. The goal is often to see the light, not the light source. A low-density strip (like 60 LEDs/meter) is fine for hidden, indirect cove lighting, but for any application where the strip itself might be visible, a high-density product is the only way to achieve a premium, flawless look.

From Dots to Lines of Light

The visual quality of the light is just as important as its durability.

The Science of Seamless Light

The human eye perceives individual points of light when they are spaced far apart. By increasing the number of LEDs per meter, you reduce the space between them to the point where our eyes blend them together into one solid line. This is especially important when the strip is lighting a nearby surface or when used with a diffusing cover. High-density strips produce a more professional and visually pleasing effect.

Beyond Density: LED Quality5

A top-tier strip doesn’t just have more LEDs; it has better LEDs. All the LEDs on a single reel must come from a very tight color bin (like a 3-Step MacAdam ellipse). This an advanced quality control step that guarantees every single LED produces the exact same shade of white, eliminating any pinkish or greenish tint variations along the strip.

| LED Density | LEDs per Meter | Visual Effect | Best Application |

|---|---|---|---|

| Standard Density | 60 | Noticeable Dots | Hidden, indirect lighting (coves) |

| High Density6 | 120+ | Smooth, Line of Light | Visible locations, architectural accents |

Why is UL Listing a Top 10 Must-Have for Safety?

You found an incredibly cheap outdoor power supply online. It works, but you have a constant worry in the back of your mind: is it safe? If it fails, could it cause a fire, and would you be held liable?

A UL or ETL Listing is a non-negotiable feature because it is independent proof of safety and performance. This certification ensures the product has been rigorously tested to prevent fire and electrical shock, and that its waterproof claims are real.

I often have to warn clients about the danger of counterfeit or non-certified products. A UL mark isn’t just a sticker; it’s an entire system of safety and accountability. Using unlisted components on a job site can void insurance policies and expose a business to massive liability. A top product must be a safe product.

The Assurance of Third-Party Testing

A certification moves a product’s claims from marketing promises to verified facts.

What Does a UL Test Involve?

A UL certification7 is not an easy or cheap process. To get listed, a product must survive a battery of brutal tests designed to simulate worst-case scenarios:

- Fault Testing: They intentionally short-circuit and overload the product to ensure its internal protections work and it fails safely.

- Environmental Testing: They place it in heat chambers, humidity chambers, and subject it to extensive water spray and submersion tests to verify the IP rating is accurate.

- Material Testing: They ensure all plastic components are flame-retardant and that the construction can withstand physical abuse.

Protecting Your Business

For a professional like Tom, using UL Listed products is a critical business practice. It demonstrates due diligence to clients and inspectors, it ensures compliance with local electrical codes, and it provides a powerful layer of legal and financial protection for your company.

| Product Status | Safety Assurance | Liability Risk | Performance Verification |

|---|---|---|---|

| Non-Certified | None | Extremely High | None (Claims Unproven) |

| Verified UL/ETL Listed | 3rd-Party Verified8 | Low | IP Rating Confirmed |

Conclusion

A top 10 outdoor LED strip is defined by its specs, not its brand. Look for the combination of IP67 silicone protection, 24V power, high-density LEDs, and full UL certification.

-

Understanding IP67 certification is crucial for choosing durable outdoor products that withstand water exposure. ↩

-

Exploring silicone’s properties reveals why it’s superior for outdoor applications, ensuring longevity and performance. ↩

-

Understanding voltage drop is crucial for optimizing lighting systems and ensuring consistent brightness. ↩

-

Exploring the benefits of a 24V system can help you achieve better lighting performance and efficiency. ↩

-

Learn how LED quality impacts color consistency and overall lighting performance for your projects. ↩

-

Explore the advantages of high density LED strips for achieving a smooth, professional lighting effect. ↩

-

Understanding UL certification can help you ensure product safety and compliance, protecting your business and customers. ↩

-

Exploring 3rd-Party Verified resources can enhance your knowledge of product safety standards and improve your business practices. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…