What Should You Look for in an Outdoor LED Strip Light?

You want to specify outdoor LED strips for a client’s project. But you worry that sun, rain, and time will degrade the product, leading to costly failures and an unhappy client.

To choose the right outdoor LED strip, focus on four key factors: a high IP rating (IP65+), durable materials (UV-resistant silicone), verified brightness (lumens per meter), and legitimate safety certifications (like UL Listing) for all components.

Choosing an outdoor LED strip isn’t just about picking a product; it’s about investing in a long-term solution. As a manufacturer, I’ve seen firsthand how cutting corners on any of these key elements can turn a brilliant design into a maintenance nightmare. Let’s break down exactly what you need to look for to ensure your projects last.

What IP Rating Do You Need for Outdoor LED Strips?

You’re designing a lighting plan for a patio, and the forecast calls for rain. Will that beautiful strip survive its first encounter with water, or will it short out instantly?

For general outdoor use exposed to rain and splashes, you need a minimum of IP65. For areas near pools or puddles, choose IP67. For any underwater application like in a fountain, you must use an IP68-rated strip.

The IP (Ingress Protection) rating is the single most important specification for any outdoor electronic product. It’s not marketing fluff; it is a standardized, testable measure of how well a product is sealed against solids (the first digit) and liquids (the second digit). Getting this wrong is the fastest way to project failure.

Decoding IP Ratings for the Real World

For outdoor projects, the first digit will almost always be ‘6’, which means the strip is completely dust-tight. The second digit is what you must pay close attention to, as it dictates its water resistance.

- IP65 – Water Jet Protection: An IP65-rated strip is protected against low-pressure water jets from any direction. This is the baseline standard for any strip that will be exposed to rain, irrigation sprinklers, or being washed down with a hose. The protection usually comes from a clear silicone coating applied to the top of the strip’s circuit board.

- IP67 – Temporary Immersion1: An IP67-rated strip can be submerged in water up to 1 meter deep for 30 minutes. This is necessary for installations at ground level where puddles might form, or for lighting around the edge of a pool or dock. These strips are typically encased in a full silicone sleeve or extrusion.

- IP68 – Continuous Submersion2: IP68 is the highest level of protection. These strips are designed to operate continuously while submerged in water, making them the only choice for installation inside pools and fountains. They feature robust, thick jacketing and permanently sealed connections.

| IP Rating | Level of Water Protection | Ideal Application Scenario |

|---|---|---|

| IP20 | None | Indoor use only (e.g., dry ceiling coves, cabinets). |

| IP65 | Protected from rain and splashes. | Patios, railings, signage, under eaves. |

| IP67 | Protected from temporary immersion. | Pathway edges, decks near pools, docks. |

| IP68 | Protected from continuous submersion. | Inside swimming pools, fountains, and water features. |

What Makes an Outdoor LED Strip Durable?

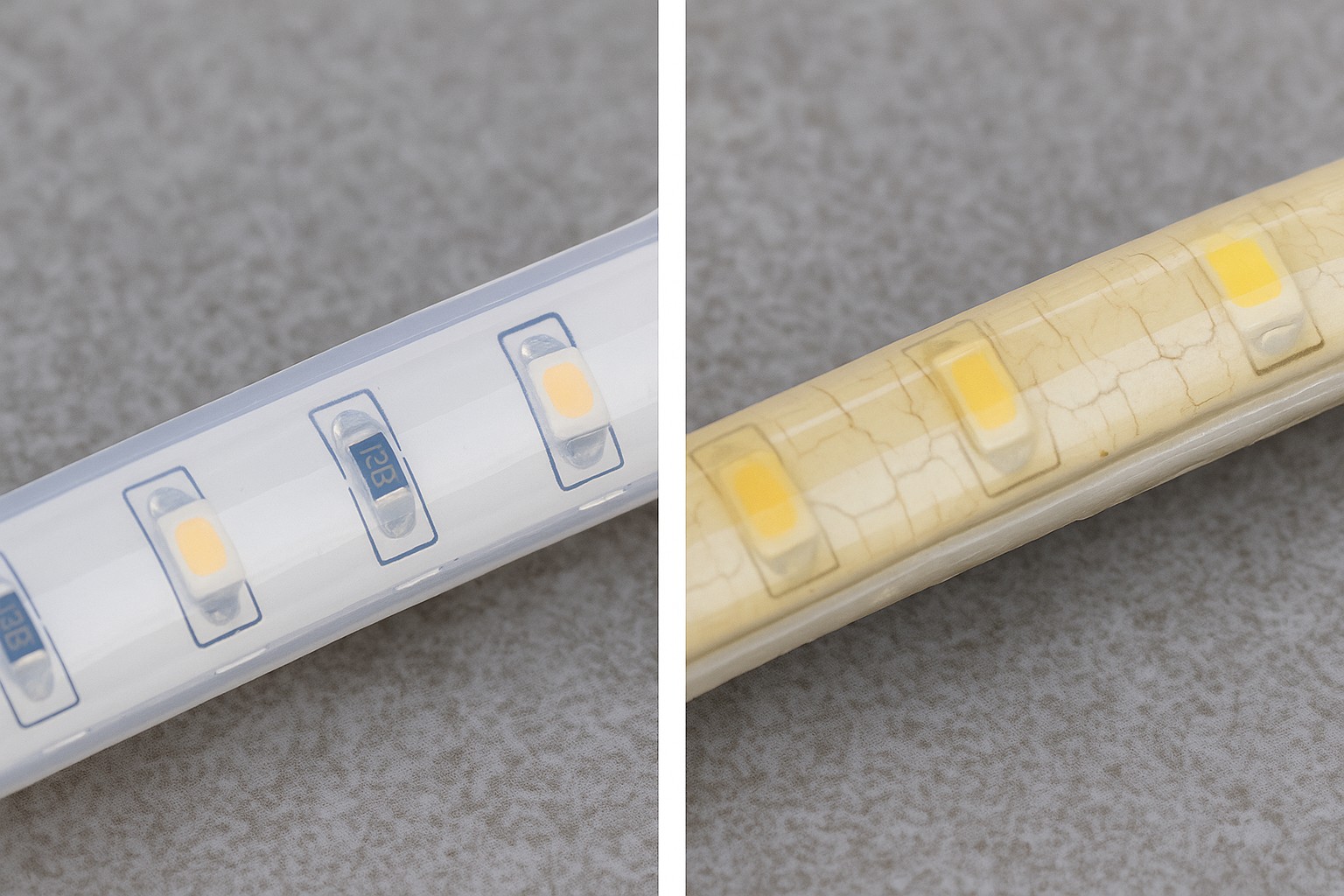

Your last outdoor strip looked great for a year, but now it has turned yellow and cracked. Why did a product advertised as "outdoor-ready" fail so quickly?

True durability comes from the jacketing material. High-quality strips use UV-resistant silicone which stays clear and flexible. Cheap strips use epoxy resin or low-grade PVC, which will yellow, harden, and crack when exposed to sunlight and temperature changes.

I once had a client in Florida whose cheap epoxy-coated strips turned brittle in just six months under the intense sun. The material is everything. The LEDs themselves can last for 50,000 hours, but that’s useless if the protective housing disintegrates. As a buyer, you must ask your supplier specifically what material they use for waterproofing. If they can’t give you a clear answer, it’s a major red flag.

The Materials Science of Longevity

Beyond the IP rating, the physical construction determines a strip’s lifespan in a harsh outdoor environment.

- The Best Choice: Silicone Extrusion3: Silicone is an inorganic polymer that is naturally resistant to UV radiation, extreme temperatures (-40°C to 200°C), and moisture. It does not yellow or become brittle. It remains flexible, which makes installation easier and prevents cracking from expansion and contraction. This is the premium material for professional-grade outdoor strips.

- The Worst Choice: Epoxy Resin Coating: Epoxy is a cheap way to achieve an IP65 rating. However, it has poor UV stability. Sunlight breaks down the polymer chains, causing it to rapidly turn yellow, which ruins the color quality of the light. It also becomes extremely brittle over time, eventually cracking and allowing moisture to destroy the electronics.

- The Foundation: PCB Thickness4: A durable strip needs a strong foundation. Look for strips built on a thick copper PCB (Printed Circuit Board), usually specified as 2oz or 3oz. A thicker PCB is better at dissipating heat away from the LED chips, extending their lifespan and improving performance. It also makes the strip physically tougher.

| Material | UV Resistance | Flexibility | Longevity Outlook |

|---|---|---|---|

| Silicone | Excellent | Excellent | 5+ years. The professional standard. |

| PVC | Good | Good | 2-4 years. A decent mid-range option. |

| Epoxy Resin | Poor | Poor (becomes brittle) | year in direct sun. Avoid for quality projects. |

How Bright Should Outdoor LED Strips Be?

You installed new lights along a building’s exterior, but they are barely visible from the street. How can you ensure the lights have the right visual impact?

Judge brightness by lumens per meter (or foot), not by watts. For subtle accents, 200-500 lumens/meter is enough. For pathway or stair lighting, aim for 300-700 lm/m. For architectural facade or wall grazing, you need 1000+ lm/m.

Clients often ask for the "brightest" strip. But "bright" is subjective. You need to match the light output to the application. Using a 1500 lm/m strip for a small residential garden path would be blindingly bright and create unpleasant glare. Conversely, using a 300 lm/m strip on a 10-story building will be a complete waste of money. Always define the goal first, then select the lumen package that achieves it.

Beyond Just Brightness

For a professional result, you need to consider not just the quantity of light, but also its quality.

- Lumens over Watts: Watts only tell you how much energy a strip consumes. Lumens tell you how much light it actually produces. Always compare products based on their lumen output and efficacy (lumens per watt) to find the most efficient and powerful option.

- Color Rendering Index (CRI)5: CRI measures how accurately a light source reveals the true colors of objects. For outdoor use where you are lighting landscaping, stone, or wood, a high CRI (90+) is crucial. A low CRI light can make beautiful red brick look dull brown and green plants look sickly.

- Color Consistency (Binning)6: For long runs on a building, it is critical that the color of the light is identical from one end to the other, and from one reel to the next. This is achieved through a tight "binning" process at the factory. Ask your supplier about their binning process (e.g., 3-Step MacAdam ellipse) to avoid visible color shifts in your installation.

| Application | Recommended Lumens (per meter) | Recommended CRI |

|---|---|---|

| Subtle Accents (under caps) | 200 – 500 lm/m | 80+ |

| Path & Stair Safety | 300 – 700 lm/m | 85+ |

| Architectural Wall Grazing | 1000 – 2000+ lm/m | 90+ |

| General Area Illumination | 800 – 1500 lm/m | 85+ |

Why Are Certifications Like UL and CE Important?

A potential supplier offers a very low price but has no safety certifications. Is it worth the risk for your project, or is this a corner you should never cut?

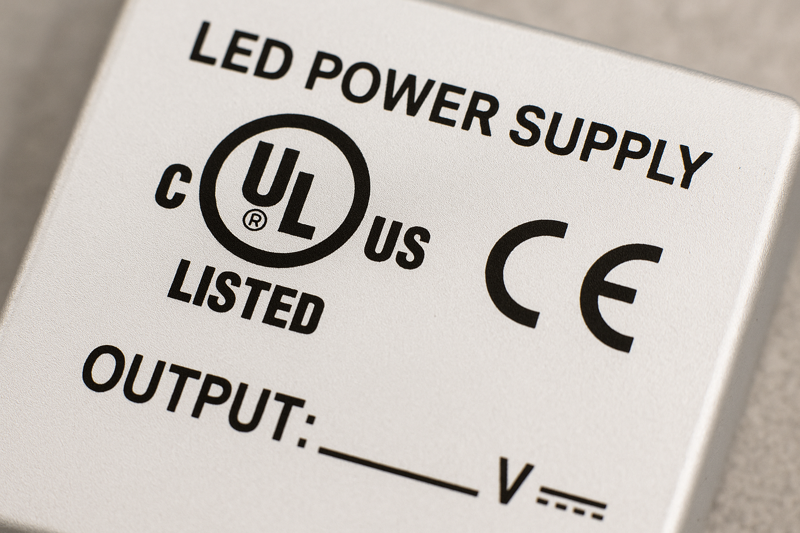

Certifications like UL (for North America) and CE (for Europe) are non-negotiable proof that a product has been independently tested for fire and electrical safety. Using uncertified products exposes you to huge liability, invalidates insurance, and can fail inspections.

This is one of my biggest frustrations and a major pain point for clients like Tom. Some suppliers will provide a falsified PDF certificate. A legitimate certification can always be verified online. For example, a UL Listed product will have a file number you can look up in UL’s public database. Always verify. The safety of your client’s property and your company’s reputation depends on it.

Understanding What Matters

These marks are more than just letters on a label.

- UL Listing (Underwriters Laboratories)7: This is the gold standard for safety in the US and Canada. It means that samples of the product have been rigorously tested by a third-party lab to meet specific safety standards. For a complete outdoor system, both the LED strip and its power supply should be UL Listed. A "UL Recognized" component is not the same as a UL Listed final product.

- CE Marking (Conformité Européenne): This is a self-declaration by the manufacturer that the product meets the health, safety, and environmental protection standards for the European Economic Area. While it is a self-declaration, it still carries significant legal weight and requires technical documentation to back it up.

- RoHS (Restriction of Hazardous Substances)8: This certification ensures that the product is free from specific hazardous materials like lead and mercury. It’s an important indicator of a manufacturer’s commitment to environmental safety and quality.

| Certification | Region | What It Means | Verification |

|---|---|---|---|

| UL Listed | North America | Independently tested for fire and electrical safety. | Check file number on the official UL database. |

| CE | Europe | Manufacturer declares compliance with EU safety standards. | Request the Declaration of Conformity. |

| RoHS | Global | Free of specific hazardous materials (e.g., lead, mercury). | Look for the mark and ask for test reports. |

Conclusion

Choosing the right outdoor LED strip means looking beyond price. It requires focusing on a high IP rating, durable UV-resistant materials, verified lumen output, and legitimate safety certifications for a reliable, lasting result.

-

Explore this link to understand the practical uses of IP67 rated lighting, especially for outdoor installations. ↩

-

Discover why IP68 rated lighting is essential for underwater applications, ensuring safety and durability. ↩

-

Explore the advantages of Silicone Extrusion for outdoor applications, including its durability and resistance to harsh conditions. ↩

-

Learn how PCB Thickness impacts the lifespan and performance of LED strips, ensuring you make informed choices for your projects. ↩

-

Understanding CRI is essential for achieving accurate color representation in lighting, especially for outdoor and aesthetic applications. ↩

-

Exploring binning processes helps ensure uniform light color across installations, preventing unsightly color shifts. ↩

-

Understanding UL Listing is crucial for ensuring product safety and compliance in North America. Explore this link for detailed insights. ↩

-

RoHS certification is vital for environmental safety. Discover more about its significance and implications for manufacturers. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…