What’s the Real Difference Between IP65, IP67, and IP68 for Outdoor LED Strips?

You’re specifying products for an outdoor project, and the spec sheets are full of numbers. You see IP65, IP67, and IP68, but what do they practically mean? Choosing the wrong one can lead to a catastrophic failure after the first major storm, ruining your work and your reputation.

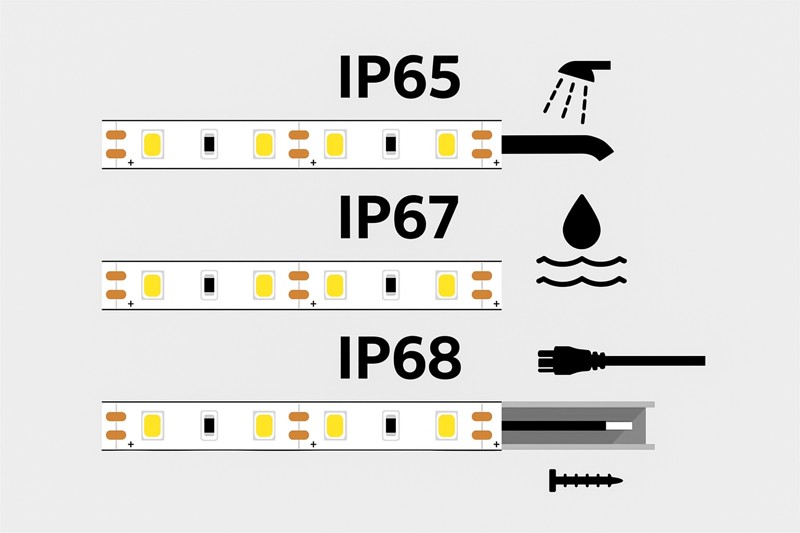

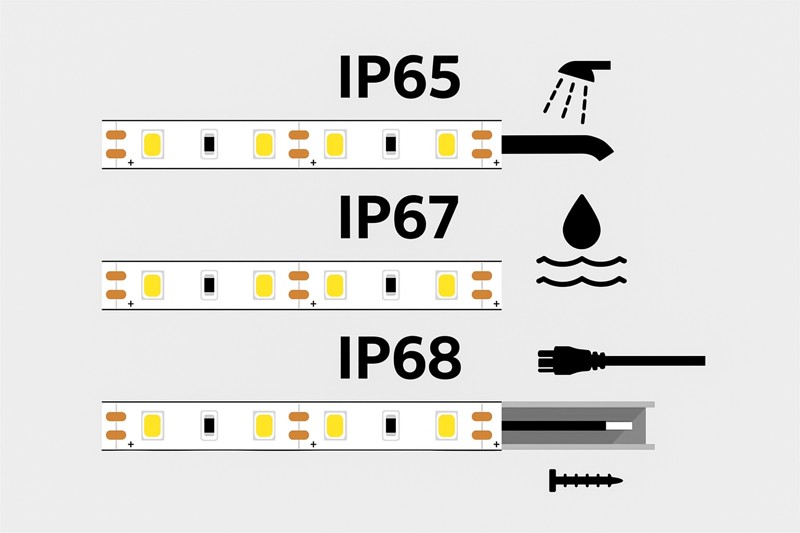

The IP rating’s second digit dictates its water resistance. IP65 is only splash-proof and not suitable for direct weather exposure. IP67 is the professional standard, offering protection against temporary immersion. IP68 is for permanent underwater submersion, like in pools or fountains.

As a manufacturer of LED strip lights for a global B2B market, I’ve seen the costly consequences of misunderstanding these simple numbers. An IP (Ingress Protection) rating isn’t just a technical specification; it’s a promise of durability. For a professional contractor like Tom, who guarantees his work, that promise is everything. This guide isn’t just about defining the numbers. It’s about translating them into the real-world performance, risk, and reliability you can expect on your job site. Let’s break down what these ratings mean for the success of your next outdoor lighting project.

What Does an IP65 Rating Really Mean for Outdoor Use?

You see a great price on an IP65-rated LED strip. It’s marketed as "water-resistant," so it seems like a smart way to save some money on a project. But you’re worried it might not hold up, turning a profitable job into a costly callback.

An IP65 rating means the strip is protected from low-pressure water jets from any direction. It can handle a light spray from a hose but is not designed to withstand heavy, wind-driven rain or any form of submersion. It is not truly weatherproof.

This is the most misunderstood rating, and frankly, the most misused in marketing. The "5" in IP65 sounds robust, but the protection it offers is minimal for any serious outdoor application. More importantly, the construction method used for virtually all IP65 strips is a major point of failure. The rating only tells you its water resistance on day one, not how it will perform after six months of exposure to sunlight and temperature changes. For any part of an installation that will be directly hit by rain or snow, specifying IP65 is a significant, and in my professional opinion, an unacceptable risk.

A Deeper Dive into the Failures of IP65

Let’s dissect why this rating falls short for professional use. It comes down to two factors: the inadequate level of water protection and, more critically, the material used to achieve the rating.

-

Deconstructing the Rating: IP65

The first digit, "6," is excellent. It means the strip is completely dust-tight. No dust or dirt can get inside to harm the LEDs or circuitry. The problem is the second digit, "5." The official test for this rating involves spraying the product with a water jet (like a garden hose nozzle) from all directions. This does not simulate real-world weather. It doesn’t account for:

- Wind-Driven Rain1: A heavy thunderstorm pushes water with much more force than a low-pressure jet. It can force moisture into seams and past weak seals.

- Standing Water: It offers zero protection if a puddle forms, even for a few minutes.

- Snow and Ice: Melting snow creates standing water and the freeze-thaw cycle can create micro-cracks in the coating, allowing water to enter when it melts.

-

Material Failure: The Real Reason IP65 Fails Outdoors

This is the most critical point. To achieve an IP65 rating, most manufacturers simply pour a clear epoxy or polyurethane (PU) coating over a standard indoor strip. This method is cheap, but the material is not designed for outdoor life.

- UV Degradation2: Epoxy and PU are not UV-stable. Direct sunlight breaks down the polymers. Within a year, the clear coating will begin to yellow, become cloudy, and turn brittle. This not only looks terrible and reduces light output, but the brittleness leads to…

- Cracking and Delamination3: As the coating hardens, temperature swings cause it to expand and contract at a different rate than the flexible PCB of the strip itself. This stress creates micro-cracks. Water then seeps into these cracks, gets trapped underneath, and corrodes the solder joints and resistors, causing the strip to fail. The coating literally peels away from the strip.

| Feature | IP65 (Epoxy Coated) | Professional Requirement4 |

|---|---|---|

| Water Protection | Low-Pressure Jets (Splashes) | Immersion (Puddles, Heavy Rain) |

| UV Resistance | Poor (Yellows and cracks) | Excellent (Must be UV-stable) |

| Temperature Range | Becomes brittle in cold | Remains flexible from -20°C to 50°C |

| Suitable Location | Deeply covered soffit, no rain/sun | Any direct exterior exposure |

| Verdict | Not recommended for outdoor use. | Use IP67 as the minimum. |

Why is IP67 the Professional Standard for Outdoor Lighting?

You’re quoting a high-end landscape lighting project. The client is demanding reliability. You need a product you can install with confidence, knowing it will withstand years of harsh weather without you ever having to go back to fix it.

IP67 means the strip is fully dust-tight and can be temporarily submerged in up to 1 meter of water for 30 minutes. This level of protection is achieved with a full silicone extrusion, making it the reliable, weatherproof standard for professional outdoor installations.

When a client like Tom asks me what to use for 99% of his outdoor projects, from architectural accents to landscape paths, my answer is always IP67. This rating represents the perfect balance of performance, durability, and cost for professional use. The key is that the "7" leapfrogs splash protection and moves into the realm of true waterproofing: immersion. This means it can handle heavy rain, puddles, snowmelt, and high-pressure irrigation systems without any risk of water ingress. It’s the rating that provides true peace of mind for the installer.

A Deeper Dive into IP675 Superiority

The robust performance of an IP67-rated strip comes from both the higher standard of water protection and the vastly superior materials used to construct it.

-

Deconstructing the Rating: IP67

The "7" signifies protection against temporary immersion. Why is this so much better than the "5"? Because it’s a pass/fail test under much harsher conditions. An IP67-rated product must survive being fully underwater. This capability directly translates to real-world weather resilience:

- Heavy Rain & Storms: If it can survive underwater, it can easily handle the most intense, wind-driven rain.

- Puddles and Poor Drainage: If a strip is installed near the ground, on a patio, or in an area with imperfect drainage, it will inevitably sit in a puddle at some point. IP67 ensures this is a non-issue.

- Snow & Ice: A snowdrift can cover a strip for weeks. When it melts, the strip is sitting in water. An IP67 housing prevents this meltwater from ever reaching the electronics.

-

Material Science: Why Silicone Extrusion6 is Key

Unlike the cheap epoxy coating on IP65 strips, professional IP67 strips are made using a full silicone extrusion process. A standard strip is fed through a die where a thick, complete jacket of high-quality silicone is formed around it, sealing it entirely. Silicone is a far superior material for outdoor use:

- Inherently UV-Stable7: Silicone does not yellow, cloud, or become brittle when exposed to direct sunlight. An IP67 silicone strip will look and perform the same in year five as it did on day one.

- Extreme Temperature Flexibility: Silicone remains highly flexible in freezing temperatures and stable in high heat. It will not crack during a freeze-thaw cycle, maintaining its waterproof seal for the life of the product.

- Excellent Heat Dissipation: Silicone is also a better thermal conductor than epoxy, meaning it helps pull heat away from the LED chips, contributing to a longer, more stable lifespan for the electronics inside.

| Feature | IP65 (Epoxy Coated) | IP67 (Silicone Extrusion) |

|---|---|---|

| Construction | Top-coat of epoxy | Full, seamless jacket of extruded silicone |

| Water Protection8 | Splashes only | Temporary Submersion (up to 1m) |

| UV Resistance | Poor (Yellows in 1-2 years) | Excellent (Stable for 5-10+ years) |

| Durability | Brittle and prone to cracking | Flexible, resilient, and impact-resistant |

| Verdict | Unreliable for outdoor use | The professional standard for all landscape and architectural lighting. |

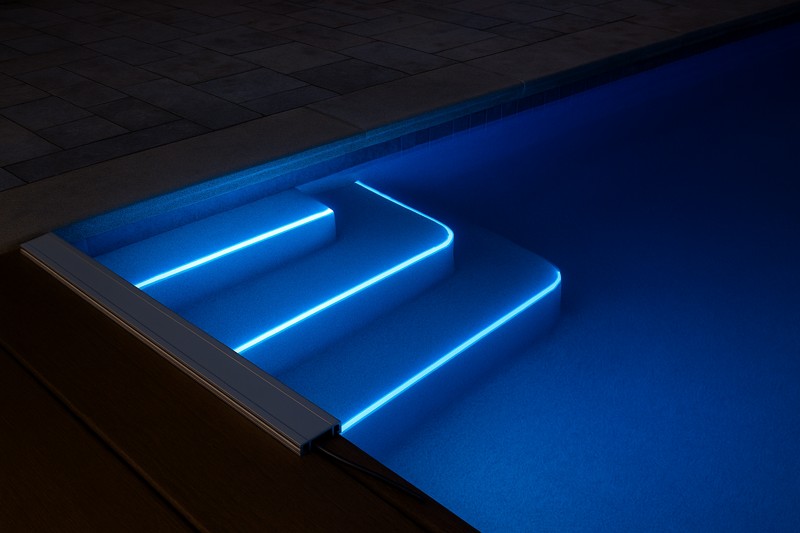

When Do You Absolutely Need an IP68-Rated LED Strip?

You have a very specific challenge: lighting the inside of a fountain or the steps of a swimming pool. The lighting will be permanently underwater, under constant pressure. An IP67 rating isn’t enough; you need the highest level of protection available.

An IP68 rating is for applications involving permanent, continuous submersion in water deeper than 1 meter. These strips are engineered to withstand constant water pressure over many years and are the only choice for pools, fountains, ponds, and marine applications.

The move from IP67 to IP68 is a significant one. While IP67 is about surviving temporary encounters with water, IP68 is about living in it permanently. This requires an even more robust construction to handle the constant pressure that water exerts at depth. For most landscape and architectural lighting, even in very wet climates, IP68 is overkill. But for those specialized projects where the lights will be underwater, it is the only rating that can be trusted to perform safely and reliably for the long term.

A Deeper Dive into Submersible-Grade IP68

Let’s explore the specifics that set IP68 apart and where it is absolutely necessary.

-

Deconstructing the Rating: IP68

The "8" signifies protection against continuous submersion under conditions specified by the manufacturer. This is a key difference: unlike the "7," the "8" is not a fixed depth. It means "better than IP67." As a manufacturer, we must specify the depth to which our IP68 product is tested (e.g., "rated for continuous submersion up to 3 meters"). An IP68 rating means the product is designed to resist water pressure. Water at depth exerts significant force, and an IP68 housing is designed to prevent this pressure from forcing water through the seals over time.

-

Construction and Installation Differences

To withstand this pressure, IP68 strips are often even more robustly engineered.

- Solid Silicone Injection: Many of our IP68 products are not just jacketed but are solid-filled with a transparent, high-grade silicone. There are no air gaps inside at all, which provides immense resistance to external pressure.

- System Integrity: An IP68 rating is useless if the connections are not equally rated. For pool and fountain installations, you must use special IP68-rated connectors and feed cables. The end caps must be factory-sealed, and any connections must be made above the waterline in a waterproof junction box. You cannot cut and splice an IP68 strip in the field and expect it to remain waterproof underwater without highly specialized kits.

- Chemical Resistance: For applications like pools, the silicone material must also be resistant to chlorine and other pool chemicals, which can degrade lesser materials.

This level of engineering and the specialized installation requirements are why IP68 products carry a premium price. They are a specialized solution for a demanding environment.

| Feature | IP67 (Silicone Extrusion) | IP68 (Solid Silicone) |

|---|---|---|

| Water Protection | Temporary Submersion (1m) | Continuous Submersion (>1m, pressure-resistant) |

| Typical Application | Landscape, Facades, Decks, Patios | Pools, Fountains, Ponds, Marine applications |

| Installation | Can be cut and re-sealed in the field | Requires factory seals and specialized IP68 connectors |

| Cost | Professional Standard | Premium / Specialized |

| Verdict | The right choice for 99% of outdoor projects. | Essential, but only for permanent underwater installations. |

Conclusion

Choosing the right IP rating is one of the most critical technical decisions for an outdoor lighting project. For professional, reliable results, avoid IP65, standardize on IP67 for all landscape and architectural work, and specify IP68 only for true underwater applications.

-

Understanding Wind-Driven Rain is crucial for selecting outdoor lighting that withstands harsh weather conditions. ↩

-

Explore how UV Degradation affects outdoor materials to make informed choices for long-lasting products. ↩

-

Learn about the causes of Cracking and Delamination to ensure your outdoor products remain durable and effective. ↩

-

Discover the Professional Requirements for outdoor lighting to ensure safety and longevity in your installations. ↩

-

Explore the advantages of IP67 ratings for better durability and performance in various environments. ↩

-

Learn why silicone extrusion is superior for outdoor applications, ensuring longevity and reliability. ↩

-

Find out how UV stability in silicone contributes to the longevity of outdoor lighting solutions. ↩

-

Discover the differences in water protection standards and why IP67 is essential for outdoor use. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…