Are Premium Outdoor LED Strip Lights Really Worth the Extra Cost?

You find two outdoor LED strips. One is half the price of the other. The cheaper one looks almost identical in the photos, and you’re tempted to save money on your project.

Yes, premium strips are worth it. The extra cost buys you superior materials that don’t yellow or crack (UV-stable silicone), verified IP ratings, consistent high-quality light (high CRI), and legitimate safety certifications (UL). These features prevent costly failures and protect your reputation.

As a manufacturer, I see exactly where the corners are cut on the factory floor to achieve a low price. It’s not magic. It’s a series of compromises in materials, quality control, and safety testing. Let’s break down a side-by-side comparison to show you precisely what you are paying for when you choose a premium product.

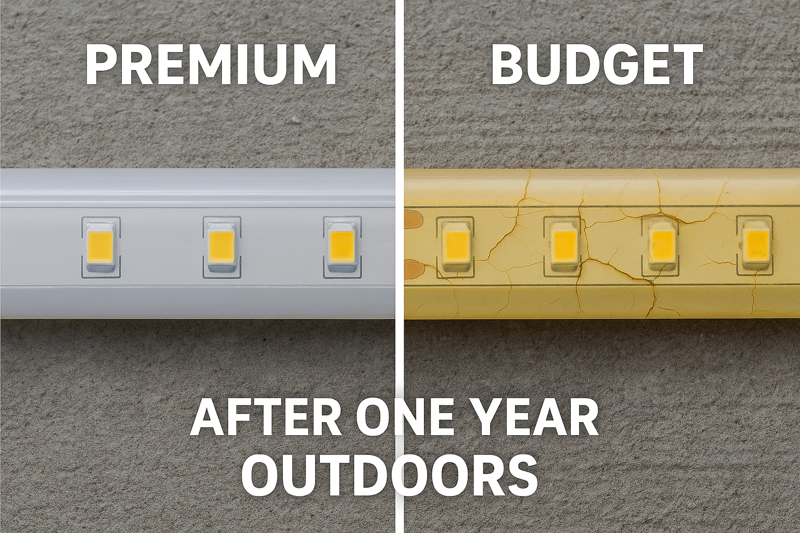

Why Do Cheap Strips Turn Yellow and Crack?

You installed a budget-friendly strip light, and it looked great for the first few months. But now it’s a yellow, brittle eyesore, and your client is calling to complain.

The yellowing and cracking are caused by cheap jacketing materials like epoxy resin or low-grade PVC. These materials are not UV-stable and are quickly destroyed by sunlight. Premium strips use pure silicone, which is naturally UV resistant and remains clear and flexible for years.

I’ve seen projects in high-sun areas like Arizona fail in under a year because the installer chose an epoxy-coated strip to save a few dollars per meter. The LEDs inside were fine, but the protective shell was destroyed, allowing water in. The durability of an outdoor strip is determined almost entirely by the quality of this outer material.

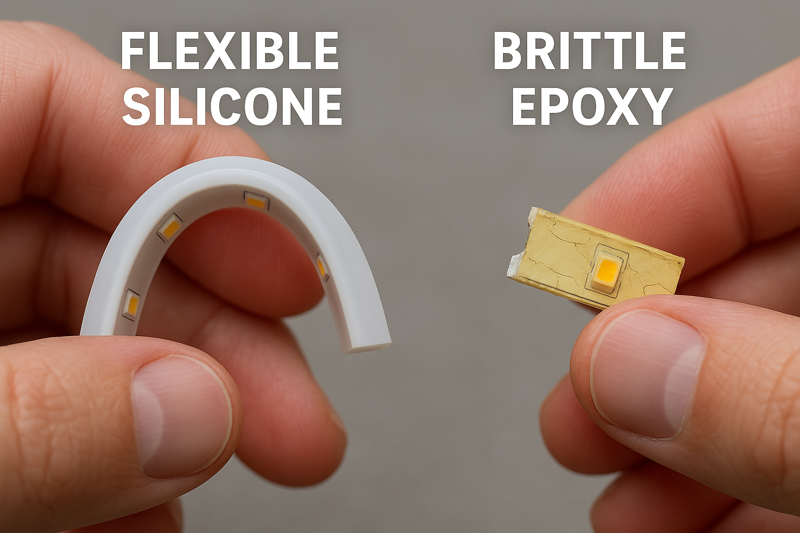

A Battle of Materials

The choice between silicone and epoxy is a perfect example of the premium vs. budget trade-off.

- The Premium Choice: UV-Stable Silicone1: Silicone is the professional standard for a reason. It is an inorganic material, making it inherently resistant to breakdown from UV radiation. It also has an extremely wide operating temperature range, so it won’t get brittle in the cold or soft in the heat. It costs more to source and process, which is reflected in the final price, but it guarantees a long, stable life for the product. It’s an investment in not having to do the job twice.

- The Budget Shortcut: Epoxy Resin: Epoxy resin is a cheap organic polymer. While it can create a waterproof seal initially, it has terrible UV resistance. Sunlight acts on it like a poison, breaking down the chemical bonds and causing that ugly yellow color. This yellowing doesn’t just look bad; it also changes the color temperature of the light passing through it. At the same time, the epoxy loses its plasticizers, becoming hard and brittle until it eventually cracks, destroying the waterproof seal.

| Feature | Budget (Epoxy Resin2 / PVC) | Premium (Pure Silicone) |

|---|---|---|

| Material Cost | Low | High |

| UV Resistance | Poor | Excellent |

| Durability | Becomes yellow and brittle | Stays clear and flexible |

| Expected Lifespan | < 1-2 years in direct sunlight | 5+ years |

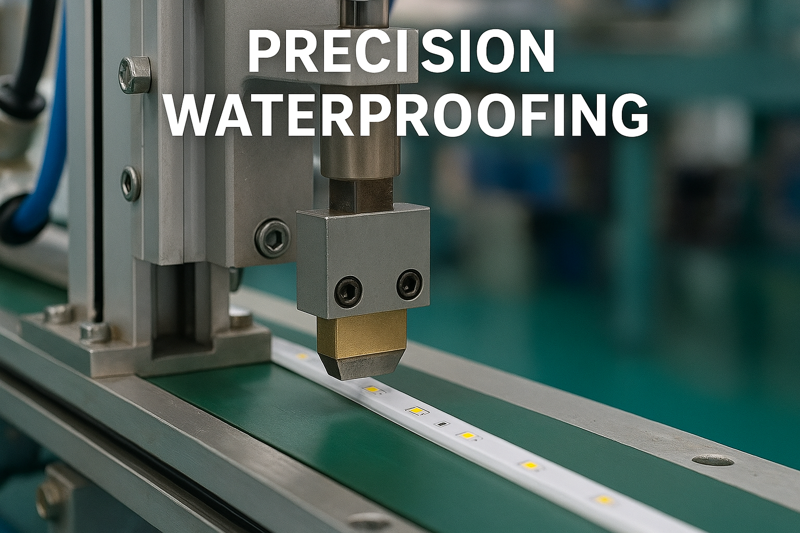

Is the IP Rating on a Budget Strip a Real Guarantee?

The budget strip you’re looking at is advertised as "IP67 Waterproof." After one heavy rainstorm, half of the strip is dead. How can this happen if the rating is correct?

Often, it can’t. A budget strip’s IP rating may be just a claim, not a tested reality. It relies on inconsistent, manually applied glue. Premium strips achieve their certified IP rating through precision manufacturing processes, like silicone extrusion and injection molding, which create a truly reliable seal.

A rating on a spec sheet is meaningless without a quality manufacturing process to back it up. Temperature changes cause materials to expand and contract. A cheap seal made with a dab of glue will quickly break apart, creating a tiny opening for moisture to enter. A premium strip, however, is often made in a single, continuous extrusion process where the housing is bonded perfectly to the internal components.

A Tale of Two Seals

Achieving a true, lasting IP rating is about much more than just coating a strip in plastic.

- Premium Manufacturing3: Consistency is Key: In our factory, premium IP67 strips are made using co-extrusion or overmolding. This means the silicone jacket and the end caps are chemically and physically bonded into a single, seamless piece. There are no gaps. Every single reel is then subjected to quality control, including underwater power-on testing, to ensure the seal is perfect before it ships. This process is expensive but guarantees reliability.

- Budget Application: A Point of Failure: The cheapest way to "waterproof" a strip is to have a worker manually apply a bead of silicone or glue to an end cap and press it on. This process is highly inconsistent. There can be air bubbles or gaps. There is no guarantee of a perfect seal. These strips rarely undergo rigorous individual testing because it adds cost. You are essentially gambling that the specific strip you received was sealed correctly that day.

| Feature | Budget Strip | Premium Strip |

|---|---|---|

| Sealing Method | Manual glue on end caps | Machine extrusion and injection molding |

| Manufacturing Consistency | Low | High |

| Quality Control Testing4 | Spot-check or none | 100% submersion testing of finished reels |

| Real-World Reliability | High risk of failure | Very high reliability |

How Does Light Quality Differ Between Budget and Premium?

You installed two reels of the same budget strip side-by-side. You notice immediately that one strip looks slightly pinkish-white, while the other is greenish-white.

This is a direct result of poor LED quality control. Premium strips use LEDs with a high CRI (90+) and tight color consistency (binning), ensuring colors are vibrant and true, and that all strips match perfectly. Budget strips use cheap, low-CRI LEDs with wide binning, resulting in a "color lottery."

For a lighting designer or architect, light quality is paramount. It’s what separates a professional installation from an amateur one. When you are lighting a beautiful stone facade or expensive landscaping, you need the light to render those colors accurately. A cheap LED with a low CRI of less than 80 can make rich materials look flat and lifeless.

What You Can’t See on a Spec Sheet

The quality of the light itself is an invisible cost that has a very visible impact.

- Premium Light: Accuracy and Consistency: Premium manufacturers buy high-grade LED chips from top suppliers. These chips are sorted into very tight "bins" (e.g., a 3-Step MacAdam ellipse), which guarantees that every single LED on every reel will produce the exact same shade of white. They also have a high Color Rendering Index (CRI), meaning they reveal the true colors of the surfaces they illuminate.

- Budget Light: The "Color Lottery": To save costs, budget strip makers buy leftover, unsorted, or lower-grade LED chips. The color consistency can vary wildly from chip to chip and reel to reel. This is why you get those ugly pink or green tints. Furthermore, they use a thinner copper PCB to save money, which leads to more significant voltage drop, causing the strip to dim more noticeably at the end of a run.

| Light Quality Metric | Budget Strip | Premium Strip |

|---|---|---|

| Color Rendering Index (CRI)5 | < 80 (Colors look dull/inaccurate) | > 90 (Vibrant, true-to-life colors) |

| Color Consistency (Binning) | Wide / Unspecified (Visible mismatch) | Tight / 3-Step MacAdam6 (Perfectly uniform color) |

| Brightness Consistency | Noticeable dimming (thin PCB) | Minimal dimming (thick 2oz or 3oz PCB) |

Why Are Certifications the Biggest Red Flag on Budget Strips?

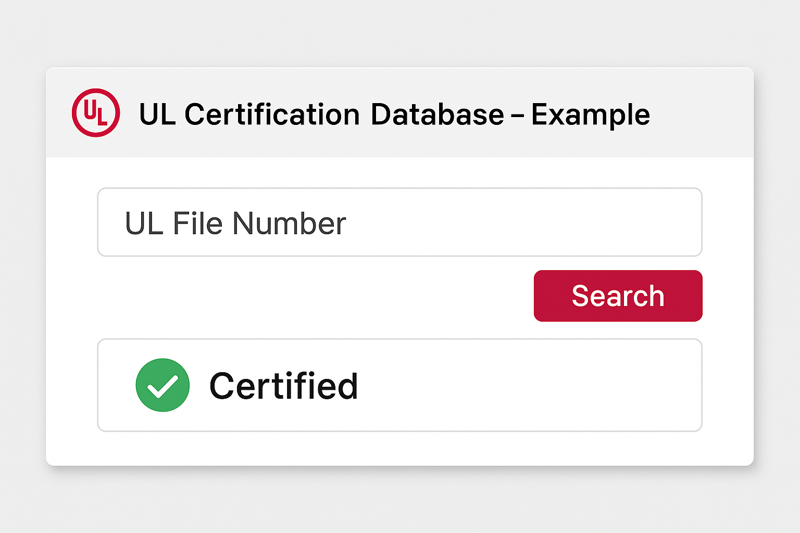

The supplier for a cheap strip sent you a PDF of a UL certificate. It looks official, but you have a bad feeling. Can you trust it?

You often cannot. Premium strips have legitimate, verifiable certifications like UL Listing, proved by a file number you can check on the UL public database. Budget strips frequently have no certifications or, worse, use falsified documents. This is a massive fire, safety, and liability risk.

This issue is one of the biggest pain points for buyers like Tom. Installing an uncertified electrical product in a commercial or residential property is a serious gamble. In the event of a fire, if the uncertified product is found to be the cause, insurance claims can be denied, and the installer can be held legally liable. A real certification is not just a piece of paper; it’s an insurance policy.

Real vs. Fake Safety

This is the one area where there can be no compromise.

- The Premium Promise: Verifiable Safety: A UL Listing is expensive and difficult to obtain. The product must undergo rigorous third-party testing for electrical safety, fire risk, and durability. The factory itself is also regularly inspected by UL to ensure standards are maintained. This process guarantees a safe, reliable product. Critically, every legitimate UL Listing has a file number that you can—and should—verify online.

- The Budget Gamble: Falsified Documents: It is incredibly easy to create a fake PDF certificate. Unscrupulous suppliers do this all the time. They are counting on you not checking. If a price seems too good to be true and the supplier is pushing a certificate that you can’t find in an official database, you are taking a huge risk. This single factor is often the clearest indicator of a supplier who cuts corners on everything else, too.

| Factor | Budget Strip | Premium Strip |

|---|---|---|

| Safety Certification | None, or a falsified/unverifiable document | Genuine UL Listing or other major certification (CE, etc.) |

| Verification | Fails online database lookup | Passes online database lookup with a valid file number |

| Liability Risk | Extremely High | Low / Covered by proper insurance |

Conclusion

The price difference between budget and premium LED strips reflects real value. Investing in a premium product protects your work, your reputation, and your clients’ safety, ultimately saving you money in the long run.

-

Explore the advantages of UV-Stable Silicone for long-lasting and durable applications. ↩

-

Learn about the limitations of Epoxy Resin, especially its UV resistance and durability issues. ↩

-

Explore this link to understand how premium manufacturing ensures the highest quality and reliability in IP67 strips. ↩

-

Learn about the importance of quality control testing in ensuring the reliability of waterproof strips. ↩

-

Understanding CRI is crucial for selecting lighting that accurately represents colors, enhancing aesthetics and functionality. ↩

-

Exploring 3-Step MacAdam helps you grasp how color consistency is achieved in premium lighting, ensuring uniformity and quality. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…