High-End Architectural Lighting: How Do You Illuminate a Facade Without Ruining the Design?

You spend months perfecting the curves and lines of a building, only to have the lighting contractor stick visibly dotted, cheap plastic strips on the exterior. The result looks like a carnival, not a landmark, and within a year, sections are dark or peeling.

For architectural applications, you must match the light source to the structure’s geometry. Use "High-Voltage" (110V/230V) strips for long vertical facade lines to eliminate drivers, and specify "Silicone Neon Flex" (Side-View or Top-View) for curved organic shapes. Always demand IP68 Solid Extrusion for any fixture installed below eye level.

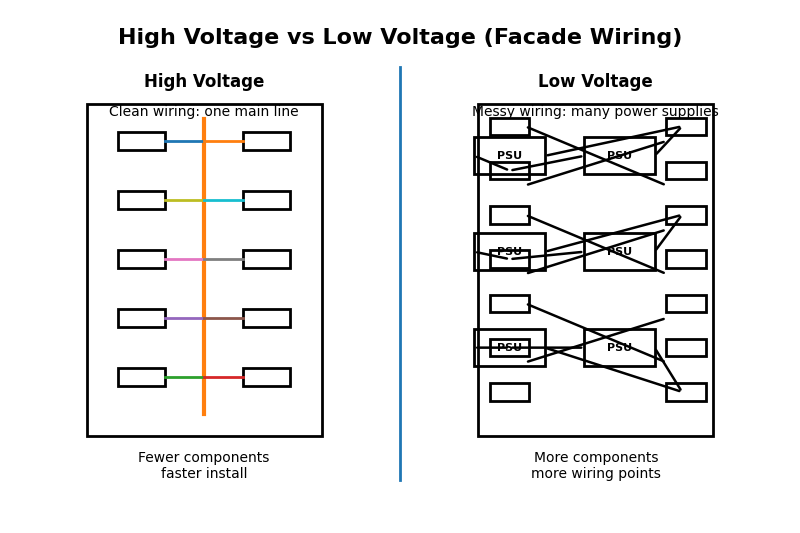

In my factory, we often receive drawings from architects that simply say "LED Strip" with an arrow pointing to a 50-meter tall building corner. If you try to do that with a standard 12V strip, you will need power supplies every 5 meters. You will have ugly junction boxes cluttering your facade. If you want to maintain the purity of your architectural vision while ensuring the lights actually turn on every night, you need to understand the three specific classes of outdoor linear lighting.

Why Should You Switch to High-Voltage (110V/230V) for Building Outlines?

Standard low-voltage DC systems are a nightmare for skyscrapers or large shopping centers. The sheer number of power supplies (drivers) required creates massive failure points and maintenance headaches.

For continuous runs over 20 meters, you must use High-Voltage AC LED strips (110V or 230V). These connect directly to the building’s mains power, allowing runs of up to 50 meters (165ft) without a single break, voltage drop, or bulky external transformer visible on the facade.

The Engineering of Scale

When you are lighting the edge of a 10-story hotel, "Voltage Drop1" is your enemy.

- The Low Voltage Trap: If you use 24V, you have to inject power every 10 meters. This means you need to hide a driver box every two floors. Architects hate this because it ruins the sleek look. Installers hate it because they have to wire 20 different boxes.

- The High Voltage Solution: Our High-Voltage strips2 (AC110V/230V) use a thick FPC (Flexible Printed Circuit) with advanced resistance. You can plug it in at the ground floor, and it will run straight up to the roof (up to 50 meters or even 100 meters) with uniform brightness.

Safety Evolution

In the past, people were scared of AC strips because they flickered or were unsafe.

- Safety: Modern HV strips are encased in a thick, double-extruded PVC or Silicone chamber. They are fully insulated.

- Flicker: We now use an "IC Rectifier" on the board itself. This eliminates the 60Hz flicker that used to make people dizzy.

- Efficiency: Because you don’t need AC-DC power supplies (which are 85-90% efficient), you actually save energy on a system-wide level.

| Feature | 24V DC Strip | 110V/230V AC Strip | Best Application |

|---|---|---|---|

| Max Run Length | 10 Meters | 50 – 100 Meters | Hotel/Office Facades |

| Power Supplies | Required every 10m | None (Direct Connect) | Building Outlines |

| Cutting Unit | Every 5-10 cm | Every 50-100 cm | Long Linear Lines |

| Safety | High (SELV) | Requires Pro Install | Inaccessible Areas (High Walls) |

How Do You Light Curved Architecture Without "Hotspots"?

Modern architecture loves curves—arches, round pillars, and winding landscape paths. Rigid aluminum profiles cannot follow these lines, and standard flexible strips "buckle" when bent sideways, forcing the light to shoot into the sky instead of the wall.

You must specify "Silicone Neon Flex" with the correct bending direction: "Side-Bend" for wrapping around columns and curved walls, or "Top-Bend" for archways and vertical coves. These products use a milky silicone diffuser to blur individual LED dots into a single, seamless ribbon of light.

Understanding Bending Physics

Standard LED strips are like a belt; they can bend around your waist (Top-Bend), but they cannot bend sideways (Side-Bend) without puckering.

- Side-Emitting Neon3 (The Snake): If you are outlining a kidney-shaped pool or highlighting a curved garden path, you need Side-View Neon. The LEDs are mounted on the side of the internal board. This allows the strip to snake left and right while shining light upwards or outwards.

- Top-Emitting Neon (The Arch): If you are lighting under a rounded bridge arch or a dome, you need Top-View Neon.

The Material Difference: Silicone vs. PVC

For architectural projects, never use PVC Neon.

- The Yellowing Test: PVC neon turns yellow in the sun within 6-12 months. It makes a white building look dirty.

- The Silicone Advantage4: We use optical-grade silicone. It is UV stable. It feels soft to the touch and repels dust. More importantly, silicone diffuses light better. It absorbs the harsh pixelation of the LED chips and outputs a "gas-neon" look that feels premium.

| Product Type | Bending Direction | Light Direction | Application Example |

|---|---|---|---|

| Standard Strip | Top-Bend only | Upwards | Straight shelving, coves |

| Side-View Neon | Left / Right | Sideways | Curved paths, Signage letters |

| Top-View Neon | Up / Down | Upwards | Arches, Domes, Roof edges |

| 360° Neon | Any direction | All around | Hanging artistic pendants |

When Is IP68 Mandatory for Landscape Features?

Outdoor lighting is often placed at ground level—in gardens, along driveways, or near fountains. Contractors often think IP65 (Splash proof) is enough. They are wrong.

For any ground-level or water-adjacent application, you must use IP68 "Solid Injection" strips. Rainwater pools on the ground, creating temporary submersion conditions that will penetrate IP65 and IP67 coatings within weeks via capillary action.

The Myth of IP65

IP65 means "protected against water jets." It is fine for a wall light under a roof overhang. It is useless for landscape.

When it rains, water doesn’t just hit the ground; it pools. If your light is installed in an aluminum channel in the driveway, it will be underwater for hours.

- Capillary Action5: As the light heats up and cools down, the air pressure inside the strip changes. This creates a vacuum effect. It sucks moisture through the wire insulation and into the strip. This is why your garden lights fail after a thunderstorm.

The IP68 Solid Injection Process

To solve this, my factory uses a Solid Silicone Injection6 machine.

- Hollow vs Solid: We don’t use a hollow tube. We fill the tube completely with liquid silicone.

- No Air Gaps: Because there is no air inside, there is no expansion/contraction. There is no vacuum to suck in water.

- The Anti-Siphon Wire: We use a special connector with a "water stop" block inside. Even if you cut the wire in a puddle, the water cannot travel up the wire and enter the LED strip.

| IP Rating | Protection Level | Allowed Location | Failure Risk |

|---|---|---|---|

| IP65 | Splash / Spray | Under Soffits | High (if puddles form) |

| IP67 | Temporary Dip | Vertical Walls | Medium |

| IP68 (Solid) | Continuous Underwater | Fountains / Ground / Steps | Zero |

Conclusion

Architectural lighting is permanent infrastructure. By choosing High-Voltage AC for height, Silicone Neon for curves, and IP68 Solid Injection for the ground, you respect the building’s design. Don’t let cheap lights become the blemish on your architectural masterpiece.

-

Understanding Voltage Drop is crucial for effective lighting design, especially in large structures like hotels. ↩

-

Exploring High-Voltage strips can reveal their advantages in efficiency and safety for modern lighting solutions. ↩

-

Explore this link to understand how Side-Emitting Neon can enhance your lighting design, especially for curved spaces. ↩

-

Discover why the Silicone Advantage is crucial for durability and light diffusion in architectural projects. ↩

-

Understanding capillary action is crucial for preventing moisture damage in LED lights, especially in outdoor settings. ↩

-

Exploring solid silicone injection technology can reveal effective solutions for enhancing the durability and waterproofing of LED lighting. ↩

Related Articles

Does Your Patio Lighting Attract Customers or Drive Them Away?

You invest heavily in outdoor furniture, landscaping, and menus, yet the patio feels cold and uninviting. Harsh, flickering, or poorly…

Why Do Commercial Outdoor LED Strips Fail and Damage Your Business Image?

You spent thousands of dollars upgrading the exterior lighting of your hotel, restaurant, or retail store. It looked incredible for…

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…