How Do You Properly Mount LED Strips on Different Surfaces?

The design is flawless, the lighting is perfect. But a month later, you get the dreaded call: "The lights are falling down." A simple mounting failure has now ruined a beautiful installation and your professional reputation.

To properly mount LED strips, you must begin with a clean, dry, and non-porous surface. For most smooth surfaces, the pre-applied 3M adhesive is sufficient after cleaning. For porous or difficult surfaces like rough wood or concrete, using an aluminum mounting channel is the best practice.

Here at the factory, we invest heavily in sourcing authentic 3M VHB adhesive tape for our premium strips. We know it’s the best in the business. However, even the world’s best adhesive will fail if it is applied to a dusty, oily, or porous surface. The one piece of feedback I consistently get from my most successful clients—the ones who never get callbacks—is that they spend more time preparing the surface than they do actually sticking the strip on. This guide covers the best practices they use, ensuring your work not only looks brilliant but lasts for years.

Why is Surface Preparation the Most Critical First Step?

You rush to finish a job, peeling and sticking the strip directly onto a newly painted wall. A week later, half the strip is dangling. Your adhesive tape has pulled the paint, not adhered to the wall.

Proper surface preparation ensures the adhesive forms a permanent bond with the actual substrate, not with a layer of dust, oil, or loose paint. This step is non-negotiable for a professional, long-lasting installation and the prevention of bond failure.

The bond between the adhesive tape and the surface is a chemical bond that happens on a microscopic level. It relies on maximizing the "surface energy"—the ability of the adhesive to wet out and grip the material. Any contaminant, no matter how small, acts as a barrier that prevents this bond from forming correctly. This isn’t just theory; it’s the practical difference between an installation that lasts for a decade and one that fails in a month. I tell my clients to treat this step as the foundation of their work. If the foundation is weak, everything built upon it will eventually collapse.

The "Clean, Dry, Test" Protocol

Before you ever peel the red liner off the back of an LED strip, you should follow this simple but mandatory protocol. This process removes the three main enemies of a good adhesive bond: dust, oils, and moisture1.

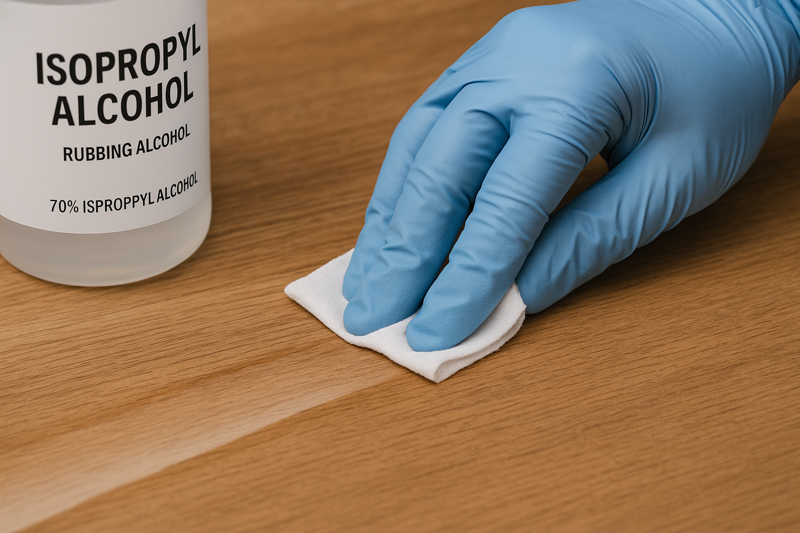

- Clean with Isopropyl Alcohol (IPA)2: Get a clean, lint-free cloth and dampen it with isopropyl alcohol (70% or higher). Do not use household cleaners, as many of them contain silicones or detergents that leave behind a residue film, which itself will prevent adhesion. Vigorously wipe down the entire surface where the strip will be mounted. The IPA will act as a solvent, breaking down any grease or oils and collecting fine dust particles.

- Ensure a Completely Dry Surface: The alcohol will evaporate quickly, but it’s important to give it a minute or two to ensure the surface is 100% dry. If you are working in a humid environment, this step is even more critical. Trapped moisture will prevent the adhesive from curing properly and will almost certainly lead to failure.

- Test the Bond (Optional but Recommended): On a very small, inconspicuous area, you can test the bond of a small piece of the tape to see how well it adheres. This is particularly useful if you are unsure about the surface material or coating.

The Science of Why This Works

This isn’t just about being tidy. It’s about chemistry and physics.

- Dust & Debris: These are physical barriers. The tape sticks to the dust, not the wall. Since the dust isn’t bonded to the wall, the strip falls.

- Oils & Grease: These are chemical barriers. Oils from hands, cooking, or manufacturing processes create a low-surface-energy film. Adhesive cannot "wet out" or spread across this film to create a bond with the substrate underneath.

- Porousness: Materials like unsealed wood or matte paint act like a sponge. They can absorb the liquid part of the adhesive, weakening its holding power. This is why sealing a surface or using a mechanical fastener is sometimes necessary.

| Preparation Step | Purpose | Common Mistake to Avoid |

|---|---|---|

| 1. Clean with IPA | Removes oils, dust, and contaminants. Increases surface energy3. | Using household cleaners that leave a residue. |

| 2. Ensure Completely Dry | Prevents moisture from interfering with the adhesive cure. | Rushing the job and not allowing the solvent to fully evaporate. |

| 3. Firm Pressure | Activates the pressure-sensitive adhesive4 for a full bond. | Lightly pressing the strip on instead of applying firm, even pressure. |

| 4. Allow to Cure | Gives the adhesive time to build to its maximum bond strength. | Putting stress on the strip (e.g., hanging wires) immediately after mounting. |

What is the Best Way to Mount LED Strips on Wood, Drywayll, or Plaster?

Your client wants seamless accent lighting on a custom-built wooden bookshelf or in a painted drywall cove. The surface seems smooth, but you worry about the long-term hold of just using the adhesive tape.

For smooth, sealed, and painted surfaces, proper cleaning followed by the strip’s 3M adhesive is effective. For unsealed, porous, or rough surfaces like raw wood or textured plaster, it is essential to use an aluminum mounting channel for a secure, mechanical bond.

Wood and drywall are the bread and butter of interior installations. They are also the surfaces where I see the most variability in results. The key difference lies in the finish. A smooth, glossy, well-cured painted surface is an excellent candidate for direct adhesive mounting. However, a porous surface like raw pine or a dusty, chalky surface like matte-finish drywall is the enemy of adhesion. Using a mounting channel in these situations is not just an upgrade; it’s a requirement. It changes the mounting problem from a chemical bond (adhesive) to a mechanical one (screws), which is always more reliable.

Direct Adhesion Method (for Ideal Surfaces)

This method only works on ideal surfaces: sealed and stained wood, wood with a polyurethane coating, or drywall painted with a satin or semi-gloss finish that has had at least two weeks to fully cure.

- Prepare the Surface: Follow the "Clean, Dry, Test" protocol with isopropyl alcohol. This is non-negotiable.

- Plan Your Run: Lightly mark a guideline with a pencil to ensure your run is perfectly straight.

- Apply the Strip: Peel back only a small section of the adhesive liner at a time. This prevents the exposed adhesive from picking up dust from the air or sticking to your hands.

- Apply Firm, Even Pressure: This is a crucial step that many people miss. The "VHB5" in 3M VHB tape stands for "Very High Bond," and it is a pressure-sensitive adhesive. It needs firm pressure to achieve its maximum bond strength. After sticking the strip on, go back over the entire length with your thumb or a small roller to press it firmly into place.

- Allow Cure Time: The adhesive needs time to "set" and build to its full strength. Ideally, you should allow it to cure for 24 hours before putting any stress on it.

Aluminum Mounting Channels (The Professional Standard)

For any surface that is not perfectly smooth, sealed, and clean—or for any project where absolute long-term reliability is paramount—I recommend channels to all my clients.

- Mechanical Fastening6: The channel itself is mounted to the wood or drywall with small screws. This bond will never fail. The LED strip is then stuck inside the channel, which is a perfect surface for adhesion.

- Heat Dissipation7: The aluminum acts as a fantastic heat sink, pulling heat away from the LEDs. This can significantly extend the life of the LED strip, especially for high-power models. This is a huge value-add for clients.

- Light Diffusion8: Channels come with a frosted or opal diffuser cover. This cover eliminates the "hotspots" of individual LED dots, creating a smooth, linear, and continuous line of light. For any installation where the strip itself is visible, this is an aesthetic necessity. It elevates the look from a DIY project to a high-end architectural feature.

- Protection: The channel protects the strip from physical damage, dust, and debris.

How Do You Securely Mount LED Strips on Metal Surfaces?

You’re installing task lighting under steel cabinets or creating an accent on an aluminum frame. You know metal is a great surface for adhesion, but you’re concerned about short circuits and heat management.

Metal is an excellent surface for mounting. It provides a strong bond for adhesive and acts as a superior heat sink. The key is to ensure the metal is clean and that no exposed solder points on the strip can touch the conductive surface, preventing a short circuit.

Metal is, in many ways, the ideal mounting surface for an LED strip. It’s non-porous and, if clean, provides a perfect substrate for the adhesive to bond to. More importantly, as I’ve mentioned, the number one enemy of an LED is heat. Metal’s high thermal conductivity makes it a natural heat sink, actively pulling heat away from the strip’s PCB and dissipating it into the environment. This can have a measurable positive impact on the lifespan and lumen maintenance of your LEDs. However, its electrical conductivity requires a bit of extra care during installation.

The Risk of Short Circuits

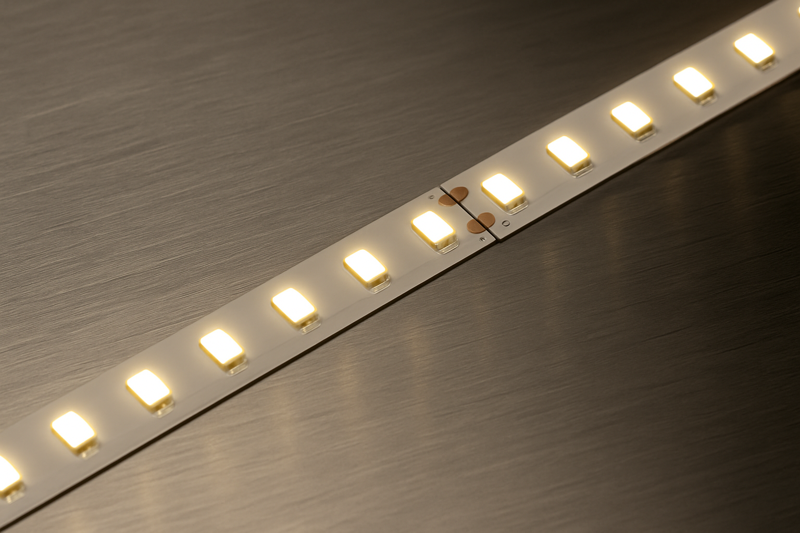

The back of a flexible LED strip is non-conductive, so you can safely stick it directly to a clean metal surface. The risk comes from the solder points9. Every half-meter or so, there are copper pads where sections are joined or where you might solder your own wires. If one of these exposed solder joints, especially the positive side, accidentally touches the metal surface, it will create a short circuit. This can either trip the power supply’s protection circuit, shutting everything down, or in a worst-case scenario with an unprotected power supply, it can permanently damage the strip.

To Mitigate This Risk:

- Inspect the Strip: Before mounting, run your finger along the strip. Make sure there are no sharp points of solder sticking out. If there are, they can be carefully filed down or re-melted to be smooth.

- Use Kapton Tape: For absolute peace of mind, especially near your own soldered connection points, you can place a small piece of Kapton tape10 (a high-temperature electrical insulation tape) on the metal surface directly underneath the solder joint.

- Mounting Channels: Once again, an aluminum channel provides a perfect solution. It offers all the heat-sinking benefits while creating a small air gap and a physical barrier between the strip’s solder points and the main metal surface.

Maximizing Thermal Performance

To take full advantage of metal’s heat-sinking properties, you want to ensure the best possible thermal contact between the strip’s PCB and the metal surface.

- Cleanliness is Key: Any dust or oil acts not just as a barrier to adhesion, but also as a thermal insulator. A thorough cleaning with isopropyl alcohol ensures good thermal transfer.

- Thermal Adhesive Tape: While the 3M tape on our strips has good thermal conductivity, for very high-power "spec-grade" strips (20W/m or more), you can use specialized double-sided thermal adhesive tape11s. These are engineered specifically to transfer heat efficiently.

- Avoid Air Gaps: When pressing the strip onto the surface, ensure you apply firm, even pressure to eliminate any tiny air gaps12. Air is a terrible conductor of heat, and a trapped air bubble will create a hot spot on the strip.

What are the Solutions for Mounting on Difficult Surfaces like Concrete or Plastic?

Your project involves a polished concrete floor accent, lighting up a brick feature wall, or adding light to a plastic (ABS or acrylic) display case. The standard peel-and-stick method is guaranteed to fail on these tricky materials.

For rough, porous surfaces like concrete and brick, aluminum channels with robust mechanical fasteners (screws and anchors) are the only reliable option. For low-energy plastics, an adhesion promoter or primer is necessary before applying the strip.

As an installer, facing a difficult surface is where you can truly show your value and expertise. Anyone can stick a light strip to a clean piece of aluminum. Making it work reliably on rough concrete or slick plastic requires a deeper level of knowledge. Trying to use the standard adhesive on these surfaces will lead to a callback, every single time. You must switch your strategy from relying on adhesion to using mechanical fastening or surface chemistry modification.

Mounting on Concrete, Brick, and Masonry

These surfaces are the ultimate challenge for adhesives. They are porous, dusty, and uneven.

- Abandon Adhesive-Only Methods: Do not even attempt to stick a strip directly to these surfaces. It will fail.

- Select a Robust Channel: Choose a suitable aluminum mounting channel.

- Drill and Anchor: Use a masonry drill bit to drill pilot holes for your mounting clips or directly through the channel base.

- Use Wall Anchors: Insert plastic or metal wall anchors into the drilled holes.

- Screw-Mount the Channel: Securely screw the channel’s mounting clips or the channel itself into the anchors. This creates a stable, permanent base.

- Install the Strip: Now you can install your LED strip inside the perfectly smooth, clean channel. The result is a bomb-proof installation that looks incredibly professional.

Mounting on Plastics (ABS, Polycarbonate, Acrylic)

Plastics present a different challenge. Many are "Low Surface Energy" (LSE) materials. This means they have a slick, chemically inert surface that adhesives have a very hard time gripping, similar to Teflon.

- Surface Preparation: As always, start by cleaning thoroughly with isopropyl alcohol.

- Light Abrasion: For some hard plastics, you can very lightly scuff the surface with fine-grit sandpaper (400 grit or higher). This creates microscopic peaks and valleys for the adhesive to grab onto. Be careful, as this will alter the finish of the plastic.

- Use an Adhesion Promoter: The truly professional solution is to use an adhesion promoter. A product like 3M Primer 94 is a liquid that you wipe onto the plastic surface before applying the strip. It acts as a chemical "bridge," changing the surface chemistry of the LSE plastic so that the VHB tape can form a powerful, permanent bond.

- Silicone Adhesive as an Alternative: In some cases, you can use a line of high-quality clear silicone adhesive in addition to the strip’s tape. Apply small dabs of silicone every few inches, then press the strip into place. The tape will hold it while the silicone cures to form a permanent, flexible bond. This is often a good solution for outdoor or high-vibration applications.

Conclusion

The quality of your mounting is a direct reflection of your professionalism. By properly preparing your surface and choosing the right method—whether direct adhesion, channels, or primers—you ensure your installations are built to last.

-

Learn how moisture can compromise adhesive bonds and why it’s crucial to ensure surfaces are dry before application. ↩

-

Explore the uses of Isopropyl Alcohol in adhesive applications to understand its importance in ensuring a strong bond. ↩

-

Discover the concept of surface energy and its critical role in achieving effective adhesive bonds. ↩

-

Find out how pressure-sensitive adhesives function and why proper application is essential for optimal performance. ↩

-

Understanding VHB can help you choose the right adhesive for your projects, ensuring maximum bond strength. ↩

-

Exploring mechanical fastening can enhance your knowledge of reliable construction methods, ensuring long-lasting results. ↩

-

Learning about heat dissipation can help you optimize your LED installations for better performance and lifespan. ↩

-

Discovering light diffusion techniques can elevate your lighting design, creating a professional and aesthetically pleasing environment. ↩

-

Understanding solder points is crucial for ensuring safe and effective LED strip installations. ↩

-

Explore the benefits of Kapton tape for electrical insulation and its applications in various projects. ↩

-

Learn how thermal adhesive tape can enhance the performance of high-power LED strips. ↩

-

Discover why eliminating air gaps is essential for optimal thermal management in electronic devices. ↩

Related Articles

High-End Architectural Lighting: How Do You Illuminate a Facade Without Ruining the Design?

You spend months perfecting the curves and lines of a building, only to have the lighting contractor stick visibly dotted,…

Does Your Patio Lighting Attract Customers or Drive Them Away?

You invest heavily in outdoor furniture, landscaping, and menus, yet the patio feels cold and uninviting. Harsh, flickering, or poorly…

Why Do Commercial Outdoor LED Strips Fail and Damage Your Business Image?

You spent thousands of dollars upgrading the exterior lighting of your hotel, restaurant, or retail store. It looked incredible for…