How Many LEDs Per Meter Do You Actually Need for Outdoor Projects?

You have just installed a beautiful linear lighting run under a patio capstone, but when you turn it on, it doesn’t look like a solid beam of light. It looks like a runway of landing dots reflecting off the polished stone below. The client hates it. You used the standard voltage and color, but you failed to calculate the density.

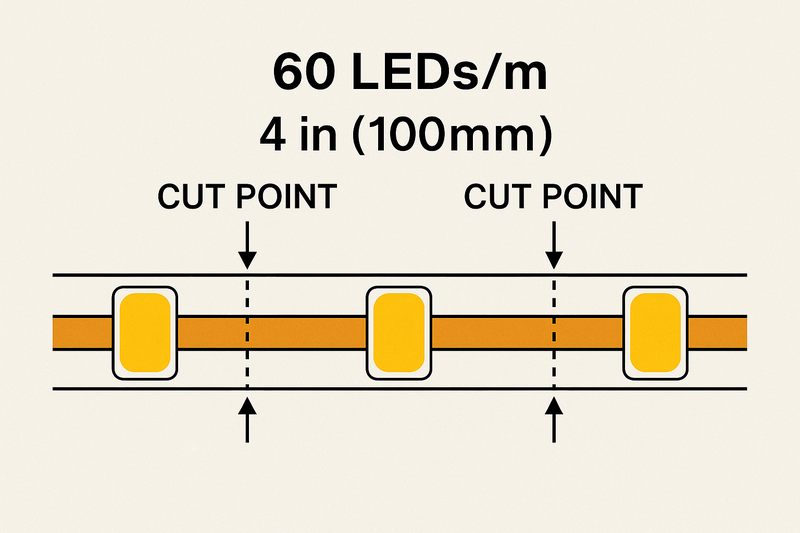

For most outdoor indirect lighting (coves, under-cap), 60 LEDs per meter is the industry standard balance of brightness and smoothness. Use 120 LEDs per meter only for direct-view applications where you need a "neon" effect without hotspots. Stick to 30 LEDs per meter solely for budget-conscious projects like tree wrapping or signage where the source is hidden.

In my experience running a factory here in Shenzhen, density is the specification that US buyers differ on the most. Some distributors think "more is better" and try to sell you 120 LEDs/m for everything. Others try to cut costs and push 30 LEDs/m. Both approaches are wrong. If you pick the wrong density, you either overpay for heat you don’t need, or you end up with the "dot effect." Let’s look at the physics behind the diode spacing so you can choose the right tool for the job.

Is 30 LEDs Per Meter Just a Cheap Trick or a Valid Tool?

You look at a roll of 30 LEDs/m, and it looks empty. There is so much PCB and so little light. It feels cheap. But if you are wrapping a massive Oak tree or backlighting a large metal sign, paying for more copper than silicon might actually be the smartest engineering move you can make.

30 LEDs/m is the ideal choice for "High-Distance" indirect lighting. If the strip is placed more than 6 inches away from the surface it is illuminating, the dots blend naturally before hitting the wall. This density creates less heat, allows for longer runs, and saves roughly 20-30% on material costs.

The Physics of Distance and Diffusion

When direct buyers from the US visit my factory, they often sneer at the 30 LEDs/m1 rolls. They call it "entry-level." I have to correct them. It is not about quality; it is about application.

Think of an LED like a flashlight. It emits light in a cone (usually 120 degrees). If you place two flashlights far apart but shine them on a wall 10 feet away, the beams overlap perfectly. You cannot see two distinct sources.

- The Math: With 30 LEDs/m, the pitch (distance between chips) is about 33mm.

- The Application: If you are lighting a cove that is 12 inches deep, that 33mm gap is irrelevant. The light spreads out before it bounces out of the cove.

- The Advantage: The biggest killer of outdoor lights is heat. A 30 LED/m strip generates half the heat of a 60 LED/m strip. Outdoors, where ventilation is poor (inside silicone tubes or sealed channels), this lower thermal footprint extends the lifespan significantly.

- Run Length: Because there are fewer resistors and diodes drawing current, voltage drop is much slower. You can often run 30 LED/m strips for 30 or 40 feet (using 24V) without needing to inject power. This saves you labor on wiring.

Use this for: Tree wrapping, very deep coves, and backlighting translucent stone where the diffuser is thick. Do not use this for shallow under-cap lighting; it will look like a connect-the-dots puzzle.

| Feature | 30 LEDs/m Specs | Contractor Benefit |

|---|---|---|

| Pitch (Spacing) | 33.3mm | Low heat generation2. |

| Max Run Length | Long (up to 15m/50ft) | Less wiring labor. |

| Cost | Lowest | Higher margin on labor. |

| Best Use | Tree Wrap, Deep Coves | Reliability in tight spaces. |

Why Is 60 LEDs Per Meter the "Goldilocks" Standard?

If you only want to stock one type of strip in your van, which one should it be? You need something that is bright enough for a barbecue area but not so hot that it melts the glue. This is where the industry settled on the number 60.

60 LEDs/m provides the perfect middle ground. With a pitch of roughly 16mm, it eliminates hotspots in any aluminum channel that is at least 0.5 inches deep. It fits 90% of residential architectural applications, balancing sufficient brightness (approx. 800-1000 lm/m) with manageable power consumption.

The Standard for Hardscape Lighting

In the B2B world, volume is king. We manufacture 60 LEDs/m3 strips at a ratio of 10:1 compared to other densities. Why? Because it aligns with the standard dimensions of American building materials.

- The Channel Ratio: To get a "line of light" without dots, the distance from the LED to the diffuser lens must be equal to or greater than the distance between the LEDs.

- The Math: With 60 LEDs/m, the gap between chips is ~16mm. Most standard aluminum profiles have a depth of 15mm to 20mm. This is a perfect match. The dots disappear just as they hit the lens.

- Brightness: A standard 5050 chip at 60 LEDs/m produces roughly 14.4 Watts per meter (at full power). This is bright enough to wash a 10-foot wall, but not so bright that it blinds people sitting on a patio.

- Inventory Safety: If you stock 60 LEDs/m, you are safe. If you use it in a "30 LED application" (like a tree), it is just brighter. If you use it in a "120 LED application," you might see faint dots, but it is usually acceptable to the average homeowner.

However, be careful with cheap 60 LED/m strips. Make sure the PCB (circuit board)4 is at least 2 ounces of copper (2oz). At 14 Watts, a thin PCB will overheat, and the voltage will drop, making the end of the strip look dim.

| Feature | 60 LEDs/m Specs | Contractor Benefit |

|---|---|---|

| Pitch (Spacing) | 16.6mm | Fits standard aluminum channels. |

| Brightness | High (~1000 lm/m) | Standard for wall washing. |

| Power Draw | ~4.4W per foot | Manageable for standard power supplies. |

| Spotting | Minimal (with diffuser) | Clean, professional look. |

When Should You Upgrade to 120 LEDs Per Meter?

Your client is a tech executive. They want their outdoor kitchen to look like a spaceship. They want that seamless, robotic, "Tron" line of light. If you put a 60/m strip in a shallow groove, they will reject it. You need density.

120 LEDs/m is required for "Direct View" applications or extremely shallow mounting depths (under 0.5 inches). This high density creates a spotless, neon-like effect even with clear or lightly frosted lenses. However, it generates significant heat and requires a dedicated aluminum heatsink to prevent premature failure.

The "Neon" Aesthetic

This is where lighting transitions from "illumination" to "decoration." When you jump to 120 LEDs/m (or even 140/m or COB), you are essentially painting with light.

- The Chip Change: Usually, with 60 LEDs/m, we use the big 5050 chips. But you cannot physically fit 120 of those big square chips on one meter of PCB. So, for 120 LEDs/m, we usually switch to the smaller 2835 chips5. They are rectangluar and can be packed tighter.

- The Pitch: The spacing drops to just 8mm. This is incredibly tight. Even a very thin diffuser lens will blur these dots together instantly.

- The Danger Zone: This is where I see contractors get burned.

- Heat: 120 LEDs generate heat. A lot of it. If you stick this directly onto wood or plastic without an aluminum channel, the adhesive will cook. The strip will detach and fall down in 3 months. You must use metal to dissipate the heat.

- Voltage Drop6: Twice the LEDs means twice the resistance points. A 24V strip at 120 LEDs/m might lose visible brightness after just 16 feet (5 meters). If you have a 30-foot run, you must inject power from both ends. If you don’t, one side will be bright white, and the other side will be dim yellow.

- The Cost: These strips are more expensive, not just because of the LED count, but because they require higher manufacturing precision. But for a high-end polished marble staircase, it is the only option that looks luxurious.

| Feature | 120 LEDs/m Specs | Contractor Benefit |

|---|---|---|

| Pitch (Spacing) | 8.3mm | Zero dots; looks like Neon. |

| Chip Type | Typically 2835 | Smaller chips, smoother line. |

| Heat Output | High | Requires aluminum channel. |

| Wiring | High Amperage | Needs power injection planning. |

What About COB Strips (Chip on Board)?

You have likely seen the new "COB" strips advertised on Instagram. They look like a continuous yellow line of phosphor. Is this the future, or just a gimmick?

COB (Chip on Board) essentially offers 300 to 500 LEDs per meter. It provides a flawlessly perfectly solid line of light with absolutely zero spotting, even with no diffuser. However, for outdoor use, COB technology is still maturing; water ingress protection (IP67) can sometimes cause color shift or yellowing of the phosphor over time.

The Ultimate Density

COB is technically the "end game" of the density war. Instead of packaging LEDs into plastic squares (SMD) and soldering them to a board, we print the die directly onto the PCB and cover the whole thing in a layer of phosphor.

- The Visual: It is flawless. You can look directly at it, and it looks like a glowing wire. For very reflective surfaces (like black granite countertops outdoors), this is a lifesaver. Standard strips reflect dots on granite; COB reflects a line.

- The Outdoor Risk: Here is the factory truth. The yellow phosphor coating on COB strips is sensitive to moisture and UV. To make it IP67 (waterproof) for outdoor use, we have to put it inside a silicone tube.

- Sometimes, the silicone reacts with the phosphor over 2-3 years, causing the white light to turn slightly green or yellow.

- Standard SMD chips (like 2835 or 5050) are encased in their own hard resin, so they are doubly protected inside the silicone tube.

- The Suggestion: Use COB for sheltered outdoor areas—like a covered lanai or a dry bar. For exposed areas pounded by rain and sun (like a fence line or pavers), stick to the proven reliability of standard 60 LEDs/m or 120 LEDs/m SMD strips. They are older technology, but sometimes "older" means "tougher."

| Feature | COB Strip | SMD 120 LEDs/m |

|---|---|---|

| Density | 300-500+ | 120 |

| Spotting | Zero (Perfect) | Very Low |

| Reflections | Solid Line | Faint Dots on Granite |

| Outdoor Life | Moderate Risk | Proven / High |

Conclusion

Stop guessing and start measuring the distance to the eye. If the light is hidden deep in a cove, save money and heat with 30 LEDs/m. If it is a standard installation in a channel, use 60 LEDs/m as your workhorse. If it is shallow, visible, or reflecting off granite, pay the premium for 120 LEDs/m or COB, but ensure you double your efforts on heat dissipation and power injection.

-

Explore this link to understand how 30 LEDs/m can enhance your lighting projects with lower heat and longer run lengths. ↩

-

Learn about heat generation in LED lighting and its impact on lifespan and efficiency, crucial for outdoor applications. ↩

-

Explore the advantages of 60 LEDs/m for optimal lighting solutions and how it enhances design and functionality. ↩

-

Learn why the thickness of the PCB is crucial for performance and longevity in LED strip lighting. ↩

-

Explore this link to understand the advantages of 2835 chips in LED applications, enhancing your lighting projects. ↩

-

Learn effective strategies to manage voltage drop in LED strips, ensuring consistent brightness and performance. ↩

Related Articles

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…