What Should You Look For in an Outdoor LED Strip Light?

You’re specifying LED strips for a high-stakes outdoor project. You need a product that will endure for years, but the market is flooded with options that look identical but have vastly different prices and hidden weaknesses.

A professional outdoor LED strip must have at least an IP67 rating, be protected by UV-resistant silicone (not PU or epoxy), run on 24V for long-run consistency, and be backed by a verifiable safety certification like UL.

As a manufacturer, I see the difference between "weather-resistant" and truly "weatherproof" every day. The right choice isn’t about one single feature. It’s about how the entire system—the coating, the electronics, and the safety approvals—works together to survive in the real world. This guide covers the four key areas you must scrutinize.

What IP Rating Do You Actually Need for Outdoor Use?

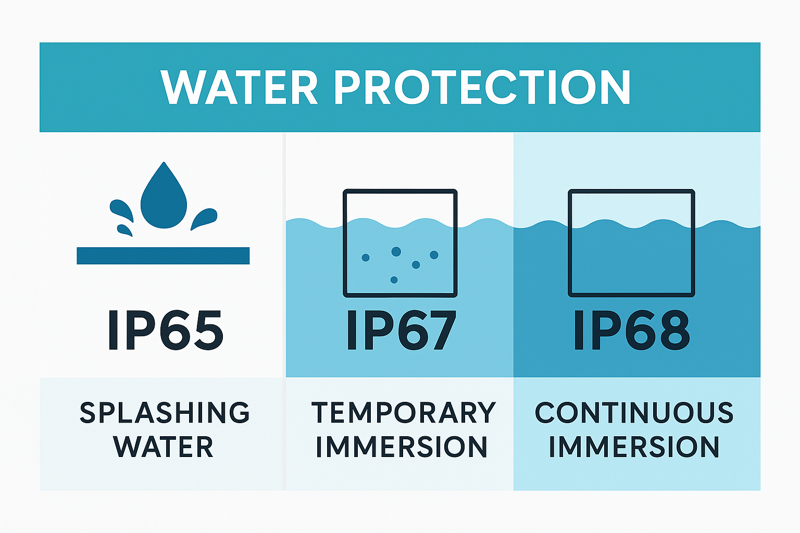

You’re looking at spec sheets and see IP65, IP67, and IP68. You know higher is better, but you’re not sure how much better. Choosing an underrated strip will lead to certain failure from water damage.

For reliable, professional outdoor use on decks, patios, or in landscaping, IP67 is the required minimum. It ensures protection against temporary water immersion like puddles or melting snow. IP65 is not sufficient for these applications.

I can’t stress this point enough with my clients. They often believe IP65 is fine because it’s rated against "water jets." But an outdoor environment isn’t about gentle jets; it’s about driving rain and pooling water. An IP67 rating means the product was literally tested to survive being submerged, providing the robust seal you need for long-term survival.

The Ingress Protection Code

The "IP" rating is a a global standard that defines how well a product is sealed against solids and liquids.

The Two Critical Numbers

- First Digit (Solids): For any outdoor strip, this should be a 6. This means it is 100% "dust-tight1." Dust and dirt can draw moisture and cause shorts, so a complete seal is essential.

- Second Digit (Liquids): This is the key differentiator for outdoor use.

- 5 (IP65): This means the strip is protected from water jets. It’s only suitable for locations that are well-sheltered and will never have standing water, like high up under a deep roof eave.

- 7 (IP672): This means the strip is protected from temporary immersion in up to one meter of water. This is the professional standard. It can handle heavy rain, puddles, and snowmelt without issue.

- 8 (IP68): This is for permanent, continuous submersion, like inside a swimming pool or fountain. It is overkill and often more expensive for standard landscape or architectural lighting.

| IP Rating | Real-World Meaning | Best Use Case |

|---|---|---|

| IP65 | Splash-proof | Sheltered vertical surfaces only; risky. |

| IP67 | Waterproof & Submersible (Temp) | The professional standard for all outdoor landscape & patio lighting. |

| IP68 | Continuous Underwater Use | For pools, ponds, and fountains specifically. |

Why Does the Coating Material Matter More Than You Think?

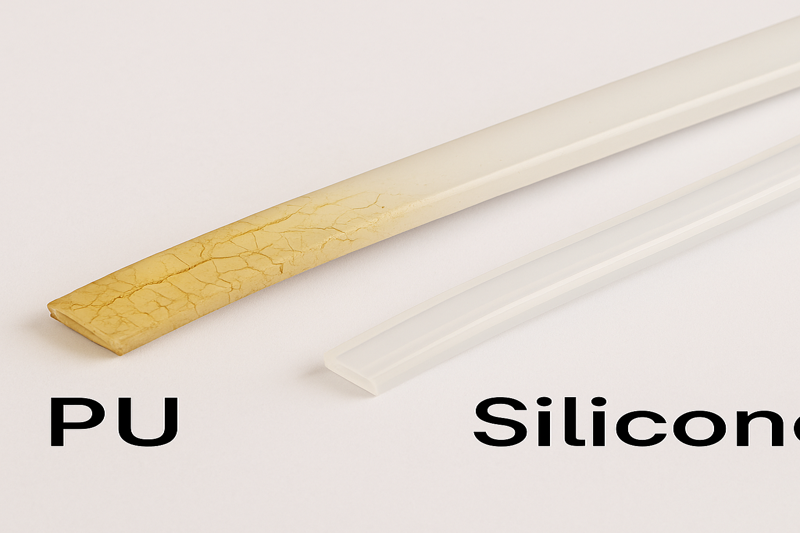

You install a beautiful, crystal-clear weatherproof strip. But just one year later, you get a callback. The strip has turned a sickly yellow color, become hard and brittle, and is cracking apart, exposing the LEDs to rain.

The protective coating must be made of high-quality silicone. Silicone is naturally resistant to UV radiation from the sun, so it will not yellow or crack. Cheaper strips use epoxy or polyurethane (PU) coatings, which will always fail under UV exposure.

In our factory’s quality control lab, we perform accelerated UV aging tests. The results are stark. After the equivalent of one year of sun exposure, the PU and epoxy samples look terrible, while the silicone samples look brand new. This isn’t a minor detail; it’s the primary factor in a strip’s physical lifespan. A failed coating means a failed IP rating.

The War Against Sunlight

The sun’s UV rays are a relentless force that breaks down plastics.

The Superiority of Silicone

Silicone3 is an inorganic material, making it fundamentally different from organic plastics like PU. Its chemical structure is incredibly stable and isn’t easily damaged by UV radiation. This allows it to remain flexible and optically clear for many years. This flexibility is crucial because it allows the strip to expand and contract with temperature changes without breaking the waterproof seal.

The Inevitable Failure of Epoxy and PU

Epoxy and polyurethane are cheaper materials, but they are a poor choice for outdoor lighting. Their organic chemical bonds are broken apart by UV rays, a process called photodegradation4. This is what causes the yellowing. As the material degrades, it loses its plasticizers, becomes rigid and brittle, and eventually cracks, often shrinking and pulling away from the circuit board. Once it cracks, the strip is no longer waterproof.

| Coating Material | UV Resistance | Long-Term Flexibility | Appearance Over Time |

|---|---|---|---|

| Epoxy / PU | Poor | Poor (Becomes Brittle) | Yellows and cracks. |

| Silicone | Excellent | Excellent | Remains clear & pliable. |

How Do You Ensure Consistent Brightness and Color on Long Runs?

There is nothing less professional than an LED installation where the light is bright at the start but visibly dimmer at the end. Or worse, the color shifts from a clean white to a muddy yellow over the length of the run.

For any outdoor run longer than 16 feet (5 meters), you must use a 24-volt LED strip. This minimizes voltage drop to ensure even brightness. For perfect color, you must also demand strips using LEDs from a tight, single bin for color consistency.

This is a technical point, but it’s one that my most successful clients, like Tom, understand deeply. It’s the difference between an amateur result and a professional one. Voltage drop is a predictable law of physics, and using a 24V system is the simplest way to overcome it. Likewise, inconsistent color is a sign of a manufacturer using cheap, unsorted LEDs.

The Physics of Flawless Light

Achieving a perfect line of light is about managing power and sourcing quality components.

Defeating Voltage Drop5 with 24V

Voltage drop is the gradual loss of electrical pressure as it moves along the strip. In a 12V system, this drop becomes visually apparent as dimming and color shift after about 5 meters. A 24V system delivers the same power with half the electrical current of a 12V system. Less current means significantly less voltage drop, allowing you to run strips twice as long (up to 10 meters) from a single power feed while maintaining perfect brightness from start to finish.

Guaranteeing Color with LED Binning6

When LEDs are made, there are tiny variations in their exact color output. The process of sorting them into batches with visually identical color is called binning. The highest-quality strips use LEDs from a single, tight bin (often defined by a "MacAdam ellipse"). Cheaper strips are made with LEDs from many different bins mixed together, which is why you see ugly shifts from white to green or pink along the strip.

| Feature | The Amateur Choice (Low-Cost) | The Professional Choice (High-Reliability) |

|---|---|---|

| Voltage | 12V | 24V for runs over 5 meters |

| Color Control | Unsorted LEDs (Wide Bin) | Single Bin / 3-Step MacAdam Ellipse |

| Result | Dim, inconsistent light | Bright, uniform, and color-pure light |

Are Safety Certifications Like UL Listing Really Necessary?

You’re comparing two options. One is extremely affordable but has no safety marks. The other is UL Listed and costs more. You wonder if the certification is just a marketing tactic or if it provides real, tangible value and protection.

Yes, a verifiable safety certification from a lab like UL or ETL is absolutely essential. It is independent, third-party proof that the product has been rigorously tested for electrical safety, fire risk, and that its waterproof rating is legitimate.

This directly addresses a core pain point for buyers: trust. Anyone can print "IP67" on a product, but a UL mark proves it was actually tested to that standard. For a business owner, using non-listed components is a massive liability. It can void property insurance and open you up to legal action if a failure causes damage or injury. It’s a corner no professional should ever cut.

Proof, Not Promises

A safety certification is your best defense against unreliable products.

What "UL Listed7" Actually Means

To earn a UL Listing, a product is not just inspected; it is tortured. Engineers try to make it fail.

- Electrical Safety: They subject it to power surges and attempt to create short circuits to ensure it fails safely without starting a fire.

- Durability and Construction: They test the physical enclosure for strength and ensure the materials are flame-retardant.

- Water Ingress Testing: For an outdoor product, they perform extensive, prolonged spray and submersion tests to verify the IP rating8 is accurate and not just a marketing claim.

How to Spot Fakes

This is a critical skill for buyers sourcing globally.

- Look for the Mark: The official UL or ETL logo should be on a permanent label on the product itself, not just on the box.

- Look for the File Number: A legitimate listing will have a file number printed near the mark.

- Verify Online: Go to the official UL Product iQ™ database online and search for that file number. If you can’t find it, the mark is likely fraudulent.

| Product Status | Safety Assurance | Liability for Installer | Performance Guarantee |

|---|---|---|---|

| No Certification | None | Very High | None |

| Verified UL/ETL Listing | Tested by 3rd Party | Low | IP Rating Verified |

Conclusion

To buy the right outdoor LED strip, you must look at it as a complete system. Insist on a minimum IP67 silicone body, use 24V for uniformity, and demand verifiable UL certification.

-

Exploring the concept of dust-tight can help you choose products that are fully protected against dirt and moisture, enhancing longevity. ↩

-

Understanding IP67 is crucial for selecting the right outdoor lighting, ensuring durability and performance in wet conditions. ↩

-

Explore the advantages of silicone, especially its UV resistance and long-term flexibility, making it ideal for outdoor applications. ↩

-

Understanding photodegradation is crucial for selecting durable materials, especially in outdoor settings where UV exposure is significant. ↩

-

Understanding voltage drop is crucial for optimizing lighting systems and ensuring consistent brightness over long distances. ↩

-

Exploring LED binning helps you grasp how color consistency is achieved in lighting, ensuring high-quality illumination. ↩

-

Understanding UL Listed products ensures safety and reliability, making it essential for informed purchasing decisions. ↩

-

Exploring IP ratings helps you choose products that withstand environmental conditions, ensuring durability and performance. ↩

Related Articles

High-End Architectural Lighting: How Do You Illuminate a Facade Without Ruining the Design?

You spend months perfecting the curves and lines of a building, only to have the lighting contractor stick visibly dotted,…

Does Your Patio Lighting Attract Customers or Drive Them Away?

You invest heavily in outdoor furniture, landscaping, and menus, yet the patio feels cold and uninviting. Harsh, flickering, or poorly…

Why Do Commercial Outdoor LED Strips Fail and Damage Your Business Image?

You spent thousands of dollars upgrading the exterior lighting of your hotel, restaurant, or retail store. It looked incredible for…