Why Do Commercial Outdoor LED Strips Fail and Damage Your Business Image?

You spent thousands of dollars upgrading the exterior lighting of your hotel, restaurant, or retail store. It looked incredible for the grand opening. But six months later, sections are dark, the white light has turned a sickly yellow, and the strips are peeling off the wall. Instead of attracting customers, your building looks neglected.

For commercial applications, you cannot rely on residential-grade products. You must specify commercial-grade IP68 Silicone LED neon flex or strips with "Constant Current" IC chips to ensure uniform brightness over long distances. Furthermore, prioritizing "3-Step MacAdam Ellipse" binning ensures that your brand colors remain consistent across every inch of the building.

In my years running a factory in China, I have seen shipping containers full of cheap PVC lights heading to the United States. I know exactly where they end up: in the trash after one winter. Commercial clients—architects, developers, and business owners—are not just buying lights; they are buying an asset. When you install lighting on a skyscraper or a shopping mall, the cost of the light is small. The cost of replacing that light (renting boom lifts, closing sidewalks, labor) is ten times higher. Here is how to choose specifications that save you money in the long run.

Why Is Silicone the Only Choice for Commercial Exteriors?

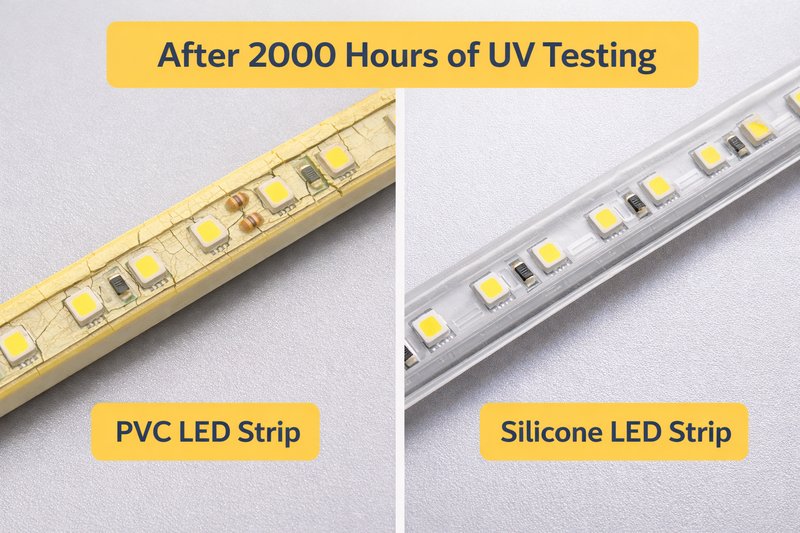

I often see tenders requesting "Outdoor Waterproof LED Strips" without specifying the material. This is the first mistake. If you use PVC (Polyvinyl Chloride) or PU (Polyurethane) on a building exterior, you are setting a timer for failure.

You must strictly demand UV-Stabilized Food-Grade Silicone extrusion. Unlike PVC, which relies on chemical plasticizers that evaporate and cause cracking under sunlight, silicone is an inorganic material that remains flexible and transparent for over five years, even in high-UV environments like Texas or Florida.

The Economics of Material Selection

When you are sourcing lights for a large project, the price difference between PVC and Silicone might seem significant on the spreadsheet. PVC is cheap. It is easy to mass-produce. But let’s look at the chemistry. PVC is a hard plastic that is made soft by adding chemicals called plasticizers. When the sun hits a PVC strip, those plasticizers "gas out" or evaporate. The material shrinks.

When the material shrinks, two disasters happen. First, the waterproof seal breaks, letting rain into the circuit board. Second, the clear casing turns yellow or brown. I have seen high-end retail stores with "Warm White" lighting that turned "Muddy Brown" in a year because they used PVC. It makes the merchandise look unappealing.

The Thermal Advantage of Silicone

There is another factor that contractors forget: Heat. Commercial lights run for 12 to 18 hours a day. PVC acts like a blanket; it traps heat inside. Heat is the number one killer of LED chips. Silicone, on the other hand, has much better thermal conductivity. It transfers heat away from the chip and into the air. By choosing silicone, you are not just buying weatherproofing; you are buying better heat management. We use a "Solid Silicone Extrusion1" process in my factory. We don’t just slide the strip into a tube; we fill the entire cavity with silicone. This eliminates air pockets where condensation can form. If you see fog inside your current lights, it is because they used a hollow tube, not solid extrusion.

| Feature | Standard PVC / PU | Commercial Silicone | Impact on Business |

|---|---|---|---|

| UV Resistance | Low (Yellows quickly) | Excellent (Stays Clear) | Maintains brand image. |

| Flexibility | Hardens/Cracks over time | Stays Soft forever | No water ingress cracks. |

| Thermal Mgmt2 | Traps Heat | Dissipates Heat | Longer LED life expectancy. |

| Cost | Low | Medium/High | Lowest Total Cost of Ownership. |

How Do You Light a Whole Building Without "Fading"?

Nothing looks less professional than a line of light that starts bright at the power source and fades to a dim glow at the end. This is called "Voltage Drop," and on large commercial buildings, it is a nightmare to manage.

For long commercial runs, you should abandon 12V and even standard 24V systems in favor of 48V LED strips or "Constant Current" designed strips. These technologies allow for continuous runs of up to 50 meters (165 feet) powered from a single end, reducing the need for expensive additional power supplies and complicated wiring labor.

The Hidden Cost of Voltage Drop

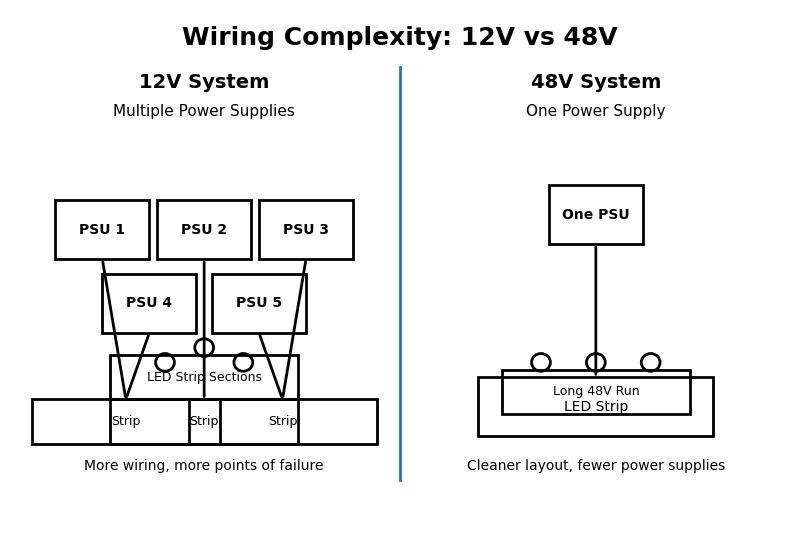

In a residential kitchen, a 5-meter (16-foot) run is fine. In a shopping mall or hotel facade, you might have straight lines that are 50 meters or 100 meters long. If you use standard 24V strips, you are limited to about 10 meters before the light starts to dim visibly. To fix this, electricians have to run "power injection3" wires every 10 meters. This requires more copper wire, more conduit, more junction boxes, and more labor hours.

The 48V Solution

In the commercial sector, we are moving heavily toward 48V Low Voltage4 systems.

- Physics: By doubling the voltage from 24V to 48V, we halve the current (Amps). Less current means less resistance in the copper traces.

- The Result: You can run a single strip for up to 50 meters (165 feet) with a single power connection at the start, and the brightness at the very end will be exactly the same as the start.

- The Installer’s Benefit: Think about the labor savings. Instead of installing five power supplies and hiding them in the ceiling, the electrician installs one heavy-duty driver in a maintenance closet and runs one wire. The system is cleaner, has fewer failure points, and is faster to install.

Constant Current IC Technology

If you cannot use 48V (perhaps safety codes restrict you to class-2 24V circuits), you must use Constant Current (CC)5 strips. These strips have a small transistor (IC) on every cut section. This chip regulates the flow of electricity. Even if the voltage drops from 24V to 21V at the end of the line, the chip opens the gate wider to ensure the LEDs get the same energy. It guarantees uniform brightness regardless of voltage fluctuation. As a factory owner, I tell my manufacturing team: "For commercial orders, CC is the default."

| System Voltage | Max Run (Single End Power) | Installation Complexity | Best Application |

|---|---|---|---|

| 12 Volt | 5 Meters (16 ft) | High (Needs many wires) | Small Signs / Vehicles |

| 24 Volt (Std) | 10 Meters (32 ft) | Medium | Retail Shelves / Interiors |

| 24 Volt (Constant Current) | 20 Meters (65 ft) | Low | Medium Facades |

| 48 Volt | 50 Meters (165 ft) | Lowest | Skyscrapers / Large Malls |

Why Is Color Consistency (Binning) Vital for Branding?

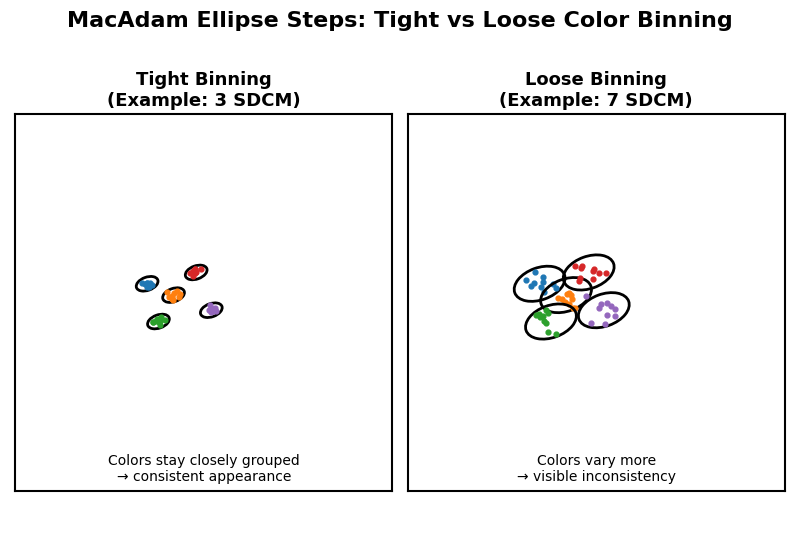

Imagine you are lighting a store for a famous brand, like Coca-Cola Red or Starbucks Green. You install the lights, and in one section, the red looks slightly orange. Or you install warm white cove lighting in a lobby, and one strip looks pinkish while the others look yellowish. This gets you fired.

Commercial projects demand strict "Binning" control, specifically within a "3-Step MacAdam Ellipse." This technical standard ensures that every single LED chip across thousands of meters emits a color indistinguishable to the human eye, preserving brand integrity and visual uniformity.

Understanding the "Bin"

LEDs are grown in a crystalline slurry. It is like baking cookies; even in the same batch, some are slightly darker, some are lighter. After we manufacture the LED chips (the light source itself), we have to sort them. This sorting process is called "Binning6."

- The Cheap Way: Low-end factories buy "Mixed Bins." They take all the leftovers—the slightly pink whites, the slightly blue whites—mix them up on a reel, and sell it cheap. To the naked eye, on the reel, it looks white. But when you shine it on a white wall, you see the rainbow of errors.

- The Commercial Way: We use a measurement standard called SDCM7 (Standard Deviation Colour Matching), often visualized as the MacAdam Ellipse8.

- 1-Step: Perfect match. Laboratory grade. Very expensive.

- 3-Step: The Commercial Standard. The human eye cannot see the difference between chips.

- 5-Step or 7-Step: Residential or Industrial grade. Noticeable differences.

The Replacement Nightmare

Here is a scenario I help clients with all the time: A year after installation, a delivery truck hits the wall and breaks 5 meters of light. The client calls you for a replacement. If you bought cheap lights, that "Bin" is gone forever. The new light you buy will not match the old light. You will have a patch of "Cool White" in the middle of a "Warm White" wall.

When you order commercial grade from a factory like mine, we record the Bin Code (CCT Rank)9. If you come back two years later, we can pull chips from that same specific coordinate on the color chart (or very close to it) to ensure the repair is invisible. This is the level of detail standard retailers on Amazon cannot provide.

| Standard | Visual Difference | Application | Cost |

|---|---|---|---|

| 3-Step MacAdam | Invisible to Human Eye | High-End Retail, Hotels, Art Galleries | High |

| 5-Step MacAdam | Slight Variation Visible | General Office, Warehouses | Medium |

| 7-Step MacAdam | Obvious Variation | Street Lights, Parking Lots | Low |

How Do You Ensure Professional Mounting and Heat Dissipation?

Adhesive tape is not a mounting system for a building. I don’t care how strong the tape is; humidity, gravity, and thermal expansion will eventually defeat it. "Sagging" lights are the hallmark of amateur work.

You must use aluminum mounting channels (profiles) for all commercial installations. These channels provide a perfectly straight mechanical fixation, protect the lights from physical impact, and significantly extend the lifespan of the LEDs by acting as a heat sink to draw thermal energy away from the board.

The Role of Aluminum

In commercial lighting, the aluminum channel is just as important as the light itself. It serves three critical functions that tape cannot perform.

- Aesthetics: A flexible strip is never perfectly straight. It waves. When you put it inside a rigid aluminum channel, it becomes a distinct architectural line. It looks deliberate and engineered.

- Protection: Cleaning crews use pressure washers. Hail storms hit facades. A bare silicone strip is tough, but a strip inside an aluminum housing with a polycarbonate cover is armor-plated.

- Heat Dissipation (The Silent Killer): As I mentioned earlier, heat kills LEDs. The aluminum channel acts as a radiator. It absorbs the heat from the back of the LED strip and releases it into the building structure or the air. Our testing shows that LEDs mounted in aluminum channels run 10°C to 15°C cooler than those mounted on wood or drywall. That temperature drop translates to an extra 10,000 to 20,000 hours of life.

Choosing the Right Diffuser

The cover (diffuser) you put on the channel changes the look completely.

- Clear Cover: Maximum brightness. Good for indirect lighting (cove lighting) where you don’t see the fixture.

- Frosted / Milky Cover: Creates a "Dotless" neon effect. If the light is visible to customers, you must use a milky cover. It absorbs about 10-15% of the light, but it eliminates the harsh glare of individual LED dots, creating a smooth, luxurious bar of light.

Installation Best Practices

When installing these channels for a business, do not just screw them in tight. Aluminum expands in the sun.

- Expansion Joints: Leave a small gap (2-3mm) between channel sections.

- countersunk Screws: Use flat-head screws so they don’t puncture the LED strip.

- End Caps: Always silicone the end caps on. Spiders and wasps love the warmth of LED lights. If you don’t seal the channel, your beautiful light bar will become a bug graveyard in a month.

Conclusion

Commercial lighting is about risk management. By investing in Silicone IP68 materials, solving voltage issues with 48V systems, and insisting on 3-Step Binning, you protect your client’s brand and your own reputation. Lighting should be an asset that generates business, not a liability that requires constant repair. Build it right the first time, and it will pay dividends for years.

-

Exploring solid silicone extrusion can reveal innovative solutions for better heat dissipation and durability in lighting. ↩

-

Understanding thermal management is crucial for maximizing LED lifespan and performance, ensuring your investment pays off. ↩

-

Understand the concept of power injection and its importance in maintaining brightness over long runs. ↩

-

Explore the advantages of 48V systems for efficiency and installation savings in commercial applications. ↩

-

Learn how CC technology ensures uniform brightness and overcomes voltage drop issues in LED lighting. ↩

-

Understanding LED Binning is crucial for ensuring color consistency in lighting, especially for long-term projects. ↩

-

Learn about SDCM to grasp how color consistency is measured in LED lighting, ensuring quality in your installations. ↩

-

Explore the MacAdam Ellipse to understand how it impacts color matching in LEDs, vital for high-quality lighting solutions. ↩

-

Discover the significance of Bin Code in LED manufacturing for maintaining color accuracy in replacements and repairs. ↩

Related Articles

High-End Architectural Lighting: How Do You Illuminate a Facade Without Ruining the Design?

You spend months perfecting the curves and lines of a building, only to have the lighting contractor stick visibly dotted,…

Does Your Patio Lighting Attract Customers or Drive Them Away?

You invest heavily in outdoor furniture, landscaping, and menus, yet the patio feels cold and uninviting. Harsh, flickering, or poorly…

Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone…