Why Do Most Marine LED Strips Fail After One Season?

You install a beautiful lighting package on a client’s yacht. Three months later, the lights are flickering, the white silicone has turned yellow, and the copper wires are black with corrosion. The ocean is relentless. If you treat a boat like a house, you will fail.

To survive the marine environment, you must use IP68 Fully Encased Silicone LED strips. Unlike PVC or Epoxy, silicone withstands saltwater and UV radiation without cracking. Furthermore, you must use "Tinned Copper" wiring to prevent "Black Wire Corrosion" and seal all connections with marine-grade glue-lined heat shrink.

At lighter deck parties, the lights look great. But in my factory, we have a machine that blasts saltwater mist onto our products for 200 hours straight. We do this because we know that salt is more corrosive than acid in the long run. A boat is constantly vibrating, flexing, and getting soaked. If you want to sell a lighting solution that lasts for years, not months, you need to understand the chemistry of materials. Let’s dive into how you can protect your reputation and your client’s vessel.

Why Is "Waterproof" (IP67) Not Enough for Saltwater?

Many installers buy "IP67" strips thinking they are safe. IP67 only means it can withstand temporary submersion in fresh water. It tells you nothing about salt, chlorine, or long-term pressure from crashing waves.

You must specify IP68 "Solid Injection" or "Hollow Extrusion" Silicone strips. Standard epoxy coatings (IP65) or PU sleeves (IP67) will chemically react with salt spray, turning brittle and yellow within months. Once the coating cracks, saltwater enters, causing immediate short circuits and galvanic corrosion.

In the LED manufacturing world, the material of the outer tube is the single most important decision you make. In the marine industry, you generally have three material choices: PVC, Polyurethane (PU), and Silicone.

The Chemistry of Material Failure

PVC and PU are cheap, which is why they are common on Amazon. However, they have a fatal flaw for marine use: plasticizers. PVC relies on chemical plasticizers to stay flexible. When the strong UV rays of the ocean sun hit PVC, the plasticizers evaporate. The tube shrinks and gets hard. When the boat hits a wave and the hull flexes, the now-rigid tube cracks. Once it cracks, water gets in, and the game is over.

Salt adds another layer of destruction. Salt crystals are abrasive and hygroscopic (they attract water). As water dries on the strip surface, salt crystals form. If the material is porous (like cheap PVC), the salt works its way into the micro-cracks, accelerating the breakdown.

The Superiority of Silicone

This is why I insist on Food-Grade Silicone1. High-quality silicone is an inorganic polymer. It does not rely on plasticizers to be flexible. This means it does not react to UV light. It does not react to salt. It stays soft and flexible whether it is 100 degrees in Florida or -10 degrees in Alaska.

We use a process called "Co-extrusion2." We push the silicone and the PCB (circuit board) through the machine at the same time. This means the silicone is not just a sleeve; it is physically bonded to the board. There is no air gap. If there is no air gap, there is no space for condensation to form when the temperature drops at night. This "Solid Silicone" approach is the only true way to prevent the "foggy lens" look that plagues cheap marine lights.

| Material | UV Resistance | Salt Resistance | Flexibility over Time | Verdict |

|---|---|---|---|---|

| Epoxy/PU | Poor (Yellows) | Low | Becomes Brittle | Avoid |

| PVC Tube | Medium | Medium | Hardens/Shrinks | Okay for Interiors |

| Silicone Extrusion | Excellent | High | Remains Flexible | Mandatory for Exterior |

Why Is Dual-Color (Red/White) Critical for Safety?

Boat lighting is not just about looking cool at the marina. It is about navigation safety. A captain who is blinded by his own deck lights cannot see a floating log or a channel marker, putting everyone on board at risk.

For cockpits, bridge decks, and helm stations, you should install Dual-Color Red/White LED strips. Red light (620-630nm) does not bleach the "Rhodopsin" in the human eye, allowing the captain to maintain night vision for scanning the horizon while still being able to read charts or move around the boat safely.

As a supplier, you need to differentiate yourself by explaining the biology of human vision to your client. The human eye takes about 20 to 30 minutes to fully adapt to true darkness. This adaptation is controlled by a chemical in the retina called Rhodopsin (often called visual purple).

The Danger of White Light

If you turn on a bright white LED to find your drink or check a gauge, that Rhodopsin3 is instantly destroyed (bleached) by the full-spectrum light. If you then look out at the ocean, you are effectively blind to the subtle contrast of waves and horizon for the next 20 minutes. At 20 knots, that is a dangerous window of time.

The Science of Red Light

Red light has a long wavelength and low energy. It is the only color that does not trigger the rapid breakdown of Rhodopsin. You can look at a red chart light, check your instruments, and then look instantly back at the dark water and see the horizon perfectly. This is why submarines and navy bridges run red.

Implementing the Solution

To sell this effectively, you need Dual-Color Strips4 (usually 3 wires or 4 wires). One channel is high-output White (6000K) for cleaning the boat, loading passengers, or docking procedures. The second channel is low-output Red (625nm) used exclusively while underway at night. You don’t need a fancy RGB controller that confuses the owner. A simple mechanical "On-Off-On" toggle switch works best for captains. Toggle up for White, Toggle down for Red, Middle for Off. It is simple, reliable, and functional.

| Light Color | Usage Scenario | Effect on Night Vision |

|---|---|---|

| Cool White (6000K) | Cleaning, Maintenance | Destroys Night Vision instantly. |

| Warm White (3000K) | Socializing, Dinner | Bad for Night Vision. |

| Blue (460nm) | Aesthetic / "Cool Factor" | Poor. Blue light focuses poorly on the retina (blurry). |

| Red (625nm) | Navigation, Chart Reading | Preserves Night Vision. Safest choice. |

What Is "Black Wire Corrosion" and How Do You Stop It?

You open a failed connection on a boat, and the copper wire isn’t copper-colored anymore. It is black powder. It crumbles in your hand. This is the plague of marine electronics, and it starts with the wrong wire choice.

You must strictly use "Tinned Copper" marine-grade wire, not standard bare copper auto wire. Salt air permeates standard insulation and oxidizes the copper, turning it black and increasing resistance until the light fails. All connections must be soldered and sealed with marine-grade heat shrink containing an adhesive liner.

In the marine world, we call this "Black Wire Disease." It is insidious because it creeps up the wire. You might cut the wire 6 inches back, and it is still black. You cut 2 feet back, and it is still black. Eventually, you have to rewire the whole boat.

The Mechanism of Failure

Salt air is humid and highly conductive. Standard PVC wire insulation (like the kind you use in cars) is actually slightly porous at a microscopic level. Over time, the aggressive salt ions penetrate the insulation. When salt meets bare copper, rapid oxidation occurs. The copper turns into copper oxide (the black powder).

Here is the physics problem: Copper is a great conductor. Copper oxide is a semiconductor. It resists the flow of electricity. As corrosion builds, resistance goes up. As resistance goes up, heat goes up. Eventually, the voltage drops so low the light turns off, or worse, the connection gets hot enough to melt.

The Tinned Copper5 Standard

If you cut open the wire I send you for a marine job, the strands look silver. That is not aluminum; that is pure copper coated in Tin. Tin is much more stable than copper and does not oxidize easily in salt air. It acts as a sacrificial shield. If you are sourcing lights for a boat, ask your supplier: "Are the lead wires tinned?" If they say no, walk away.

The Art of the Seal

Even with tinned wire, the connection point is vulnerable. Do not use "Wire Nuts" or cheap crimp connectors on a boat exterior. Moisture will get in. You must use a Western Union Splice6 (a mechanical twist) and solder it. The solder fills the gaps between strands, preventing air entry. Crucially, you must use Glue-Lined Heat Shrink. This is different from normal heat shrink. When you heat it, a layer of hot glue melts inside. It seals the wire insulation to the splice, creating a hermetic seal that is IP68 waterproof.

| Component | Automotive/Home Standard | Marine Standard |

|---|---|---|

| Conductor | Bare Copper strands | Tinned Copper strands |

| Insulation | Standard PVC | UV-Rated / Oil Resistant PVC |

| Connection | Wire Nuts / T-Taps | Butt Connectors with Heat Shrink |

| Protection | Electrical Tape | Self-Fusing Silicone Tape / Liquid Tape |

12V vs 24V: Which Voltage Should You Choose for Boats?

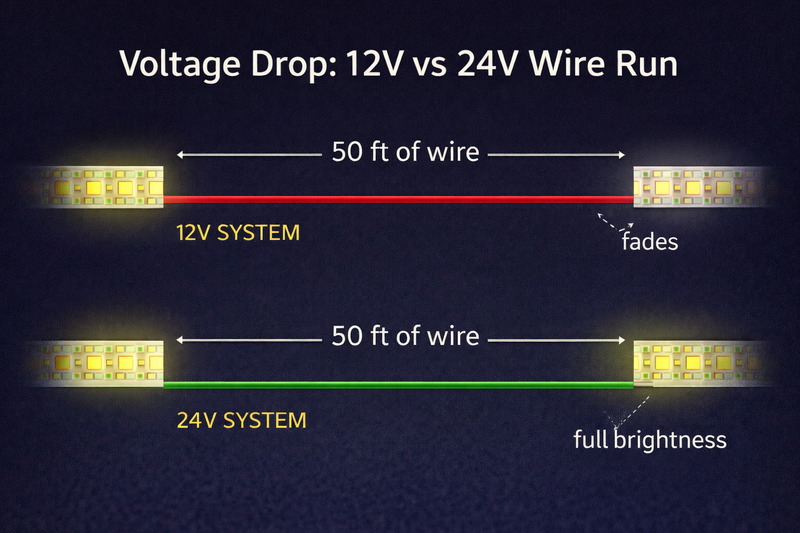

Boats are long. The batteries are often in the engine room, and the lights are 40 feet away on the bow. If you use 12V, the lights at the front will look dim and pathetic compared to the lights at the back.

For any vessel over 30 feet, specifically request 24V LED strips. Doubling the voltage halves the current (Amps), which significantly reduces "Voltage Drop" over long wire runs. This allows you to use thinner wires and ensures consistent brightness from the stern to the bow without complicated power injection.

Physics is the enemy of boat wiring. When you push electricity through a long wire, you lose pressure (Voltage) due to friction (Resistance). This is called Voltage Drop.

The Math of Efficiency

Let’s look at the numbers. Voltage Drop = Current x Resistance. The key variable here is Current (Amps).

- The 12V Scenario: Imagine you need to power 100 Watts of under-gunwale lighting. At 12 Volts, that requires roughly 8.3 Amps. Pushing 8.3 Amps through 50 feet of wire creates massive heat and resistance. You might lose 2 or 3 Volts along the way. Your lights end up receiving only 9V. They will look dim, yellow, and inconsistent.

- The 24V Scenario: To power that same 100 Watts at 24 Volts, you only need 4.1 Amps. You have cut the current in half. Less current means less friction. You might lose only 0.5 Volts. The lights receive 23.5V, which is plenty for full brightness.

System Integration

Most large yachts (50ft+) already utilize native 24V battery banks. It is a no-brainer to use 24V lights. However, even if you are working on a smaller boat with a 12V system, I often recommend using 24V lights. How is that possible?

You install a 12V-to-24V Step-Up Converter. This is a small, waterproof aluminum box. It takes the "dirty" power from the alternator (which fluctuates), cleans it, and boosts it to a perfectly steady 24V. This solves two problems at once: it fixes the voltage drop issue for long runs, and it acts as a firewall, protecting your sensitive LEDs from the alternator’s voltage spikes. This is the professional way to install lighting on a vessel.

| System Voltage | Max Run Length (approx) | Current (Example 100W) | Wire Size Required (Example) |

|---|---|---|---|

| 12 Volt | 5 Meters (16 ft) | ~8.3 Amps | Thick (10 AWG or 8 AWG) |

| 24 Volt | 10 Meters (32 ft) | ~4.1 Amps | Moderate (14 AWG or 12 AWG) |

| Advantage | Compatible with small boats | Less Voltage Drop, Cooler Run | Easier to hide wires |

Conclusion

The marine environment is unforgiving. If you use cheap materials, the salt will expose you. By choosing Silicone IP68 for the housing, Tinned Copper for the wiring, and considering Red Light for safety, you deliver a professional system. Build it to survive the ocean, and your client will trust you with their next refit.

-

Explore the advantages of Food-Grade Silicone for marine use, ensuring durability and flexibility in harsh conditions. ↩

-

Learn how co-extrusion enhances the performance of silicone products, preventing issues like condensation and fogging. ↩

-

Understanding Rhodopsin is crucial for grasping how light affects our vision, especially in low-light conditions. ↩

-

Exploring Dual-Color Strips can enhance your knowledge on effective lighting solutions for safe navigation at night. ↩

-

Explore the advantages of tinned copper for marine use, ensuring durability and resistance to corrosion. ↩

-

Learn the correct technique for a Western Union splice to ensure strong, waterproof electrical connections. ↩

Related Articles

How Do You Choose RV LED Strips That Won’t Peel Off or Flicker on the Highway?

You are upgrading a $100,000 motorhome for a client. They want underglow lighting and awning lights to be the envy…

How Can You Light Outdoor Stairs for Maximum Safety Without Blinding the Homeowner?

You have finished a beautiful tiered deck or a stone landscape staircase. The client wants lights. If you do this…

How Do You Install Driveway and Walkway LED Lights That Won’t Crack or Drown?

You want to give your client that high-end "runway" look for their driveway or a safe, glowing path to their…